Adjusting Failure Rates

There may be some instances where you do not want to use the methodology from a reliability prediction standard for failure rate calculations. For example, you may have a part with a known failure rate based on field data. Or, you may have a component that you procure at a known high quality level not accounted for in the standard you are using, and you want to adjust the calculated failure rate accordingly. These are just a few examples of reasons you may have for adjusting, modifying, or specifying a part failure rate.

Using the Specified Failure Rate

Specifying Part Failure Rates

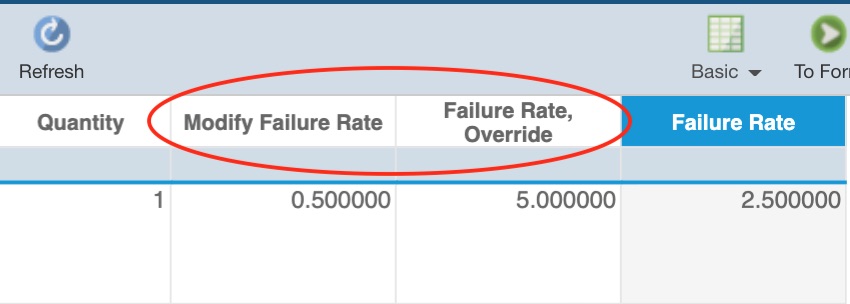

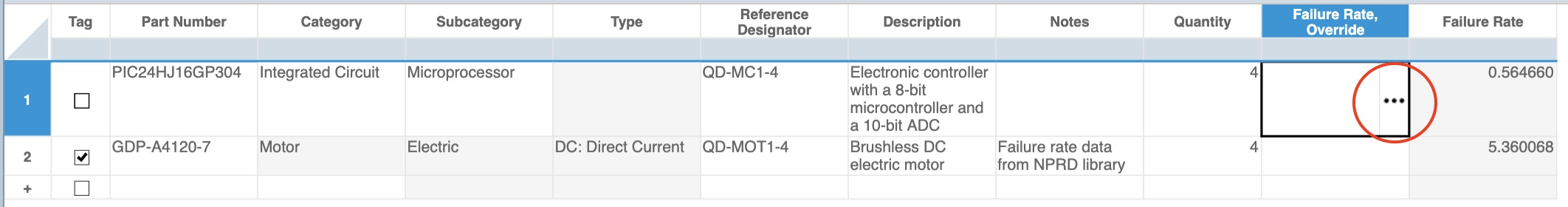

In the Parts Table, you can use the Failure Rate, Override field to set a failure rate value directly. Whatever value you enter is used as the failure rate and overrides any calculated value. Note that the value must be entered in the units as specified in the Failure Rate Multiplier setting.

Also, in the Parts Table, you can use the Modify Failure Rate field to set a multiplier for the computed failure rate value. For example, if you enter in 0.5 in the Modify Failure Rate field, the failure rate will be one-half of the computed value.

Note that your Parts Table may have to be modified to see these fields. For information on how to customize the Parts Table, refer to Customizing the Reliability Prediction Parts Table.

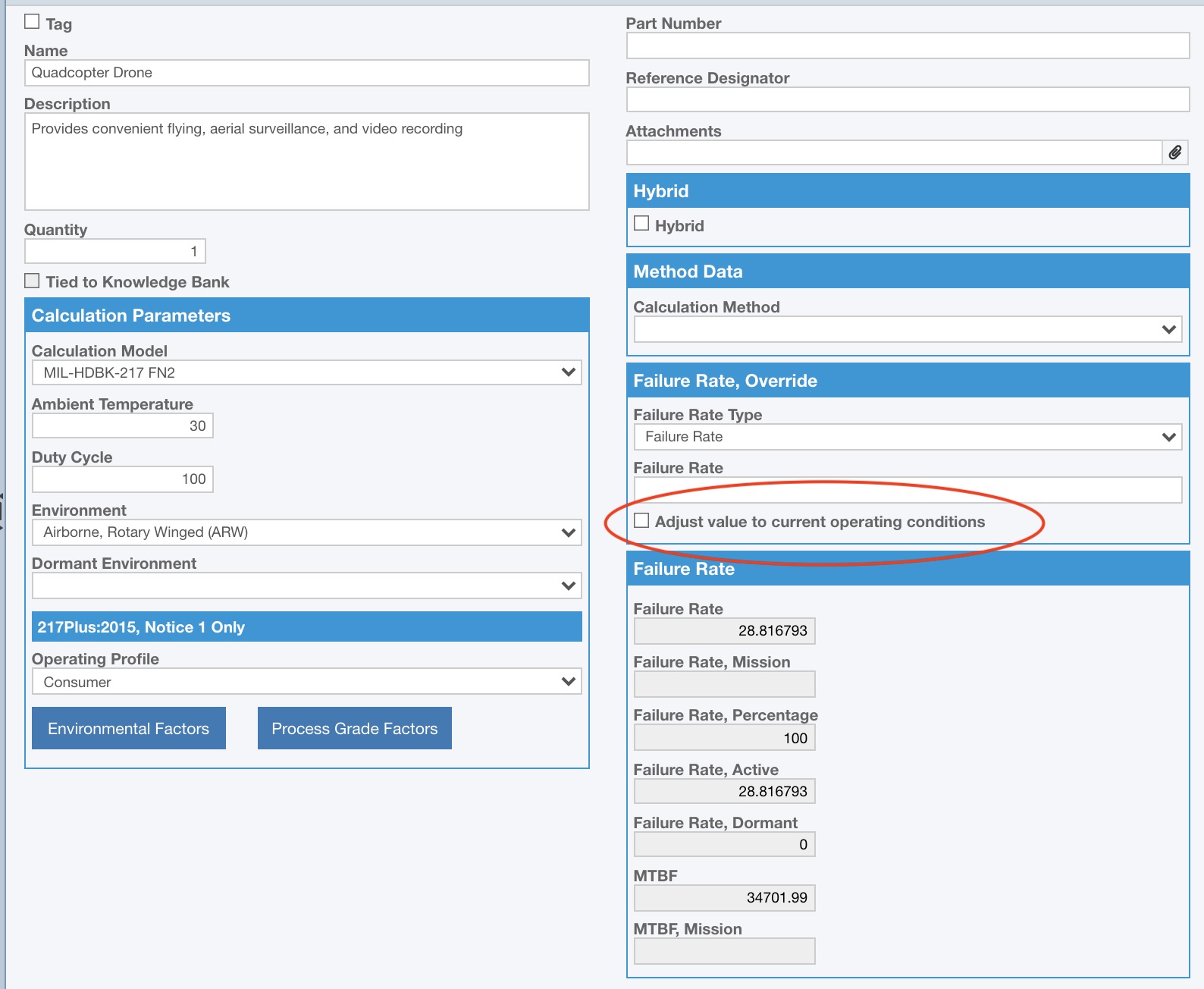

Specifying Subsystem Failure Rates

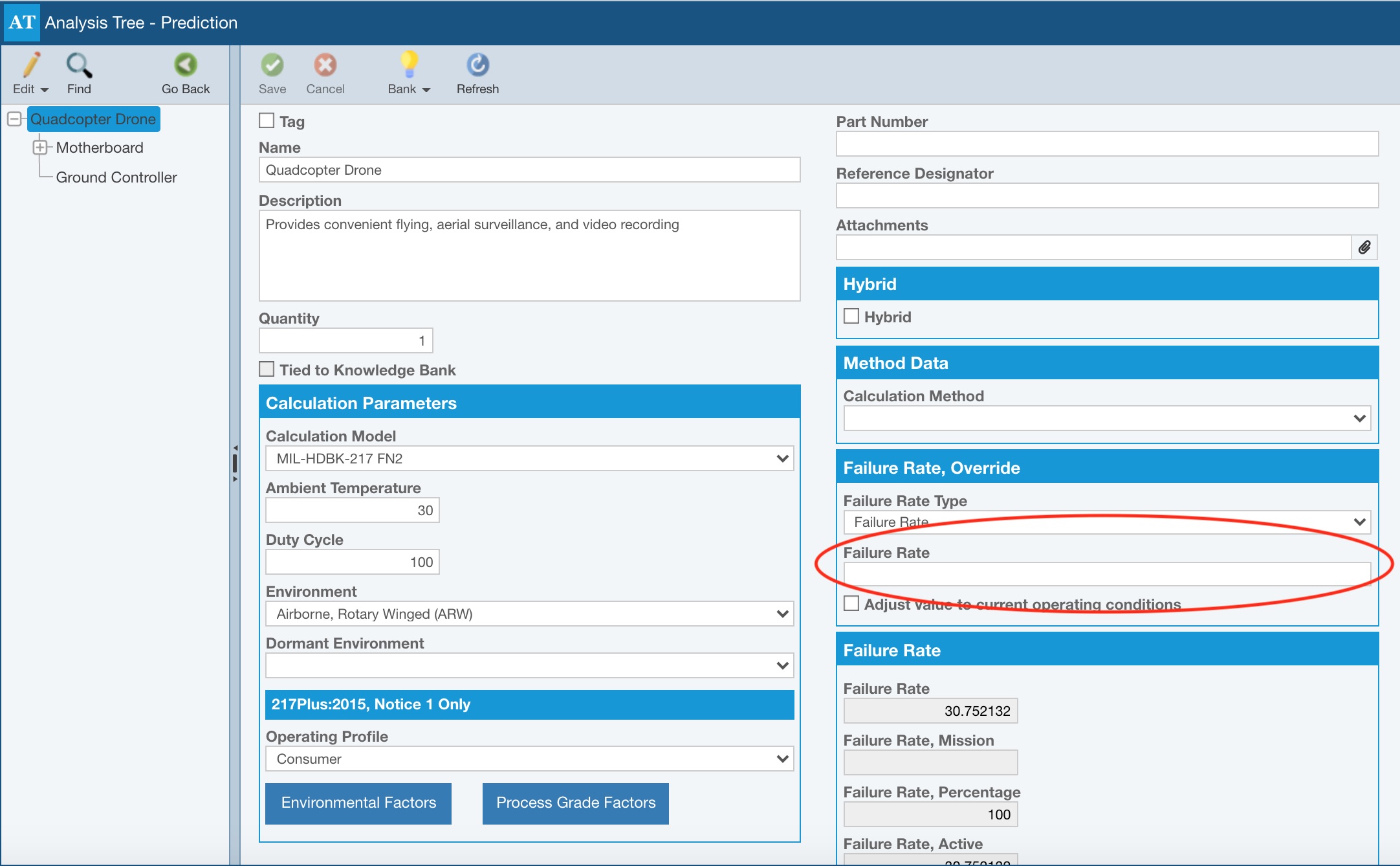

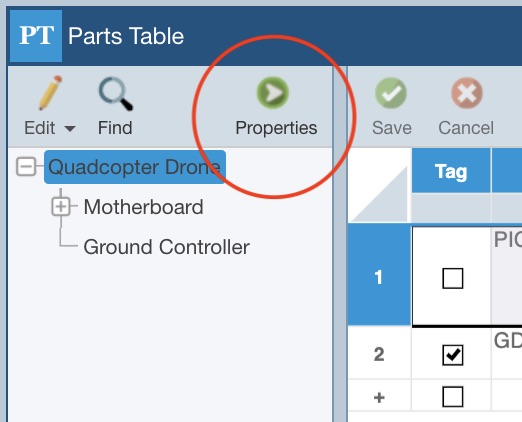

You can also adjust failure rates at the Subsystem level. In the Analysis Tree toolbar, click Properties to view the properties of the selected Analysis Tree item. On the Properties form, you can set the failure rate in the Failure Rate, Override field. The set value will override any computed value.

Using the Duty Cycle to Adjust Failure Rate

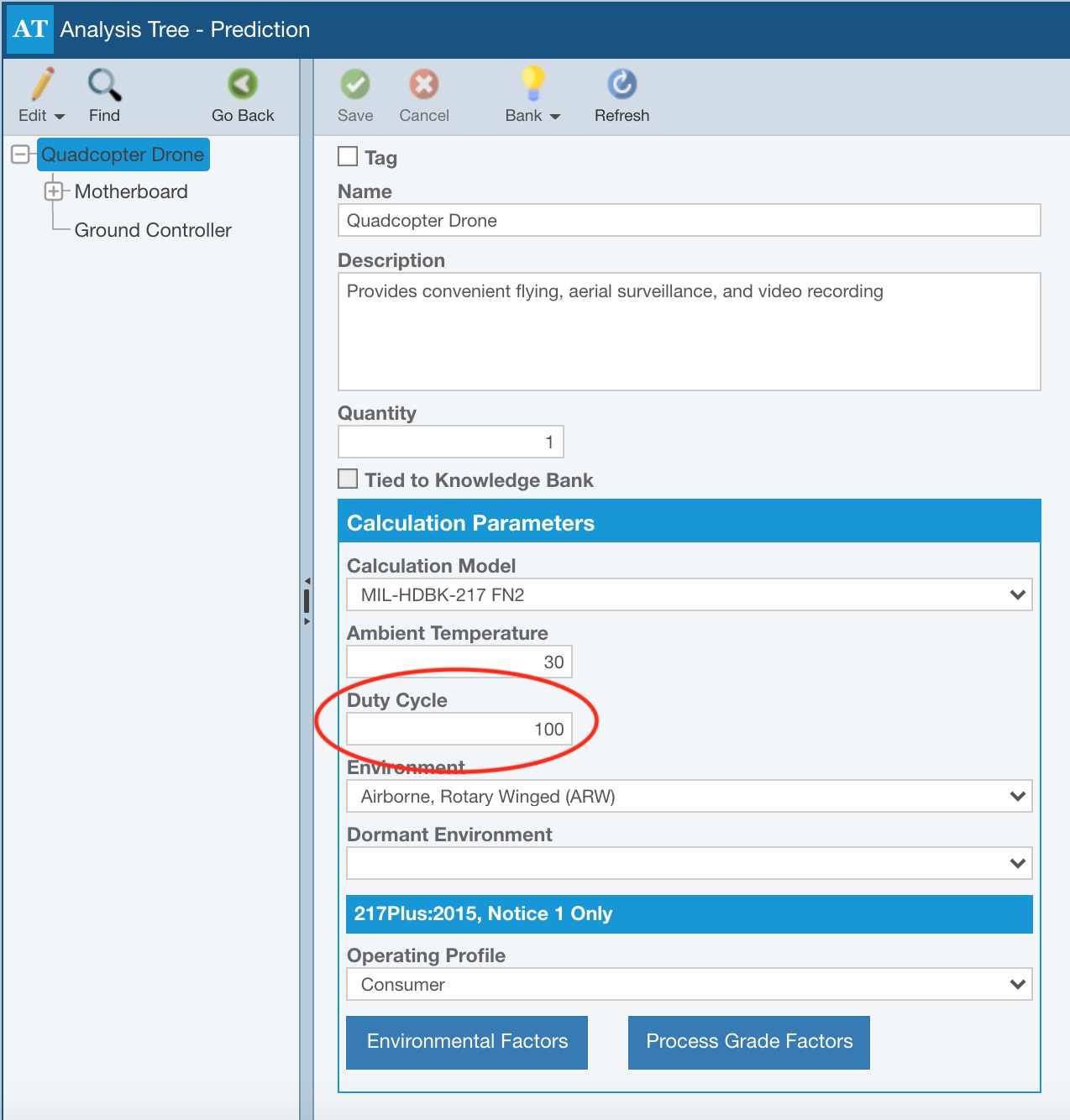

You can also use the Duty Cycle field to adjust the failure rate. For example, if the Subassembly is only operational 50% of the time, enter in 50 in the Duty Cycle field and the Subsystem failure rate will be adjusted to half the calculated value.

Adjusting Failure Rates Based on Known Failure Rates at Referenced Environmental Conditions

You can adjust a failure rate computed based on a known environment and temperature to a different environment and temperature. The adjustment is based on a table of conversion factors defined in the Rome Laboratory Reliability Engineer’s Toolkit publication.

For example, you may know the failure rate of a component when in use in a Ground Fixed environment at 30° C. However, your current operating conditions are Ground Mobile at 35° C. In this case, you can specify the failure rate along with the reference environment and temperature (Ground Fixed, 30° C) and Relyence will automatically adjust the failure rate to the operating conditions.

Adjusting Subsystem Failure Rates

To use the Failure Rate Adjust by Environment Conditions feature, select the Subsystem to adjust in the Analysis Tree pane and click the Properties button in the toolbar.

In the Properties Pane, select Adjust value to current operating conditions.

Fill in the information in the Failure Rate, Override section of the Properties pane.

Enter the known failure rate in the Failure Rate field. Note that if you want to specify by MTBF rather than failure rate, select MTBF for the Failure Rate Type and enter the MTBF value. Enter the Reference Environment and Reference Temperature values at which the failure rate was computed.

When performing calculations, the Subsystem failure rate will be adjusted to the Environment and Temperature values specified in the Calculation Parameters section of the Properties Pane.

Adjusting Part Failure Rates

To adjust Part failure rates, click the [...] button in the Failure Rate, Override field in the Parts Table. If this column is not on your Parts Table, see the Customizing the Reliability Prediction Parts Table topic for details on how to customize it. Note also that the name of the Failure Rate, Override field may have been customized.

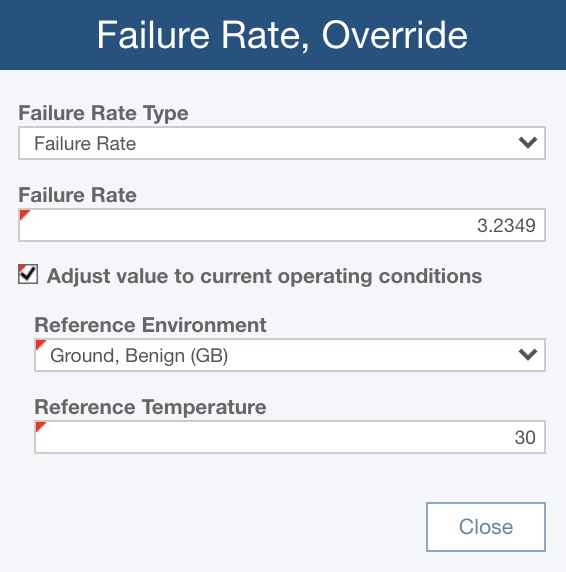

The Failure Rate Override dialog appears.

Enter the known failure rate in the Failure Rate field. Note that if you want to specify by MTBF rather than failure rate, select MTBF for the Failure Rate Type and enter the MTBF value. Enter the Reference Environment and Reference Temperature values at which the failure rate was computed.

Click Close to close the dialog. Click Save on the toolbar to save your changes.

When performing calculations, the Part failure rate will be adjusted based on the operating environment and temperature of the Part.