Performing Optimal Replacement

Within Relyence RBD, for any RBD, you can perform Optimal Replacement analysis.

Replacement options for components represented by Blocks in RBD include:

- Preventive replacement - replacement prior to block failure

- Corrective replacement - replacement after a block failure

For some components, performing preventive replacement may be more cost-effective than performing corrective replacement. Optimal replacement analysis can help determine the best time for planned component replacement, or preventive replacement.

To set up and perform Optimal Replacement analysis in Relyence RBD, select your RBD in the All RBDs pane and make sure the RBD tab is selected showing the block diagram. Then, from the Sidebar, select Tools>Optimal Replacement.

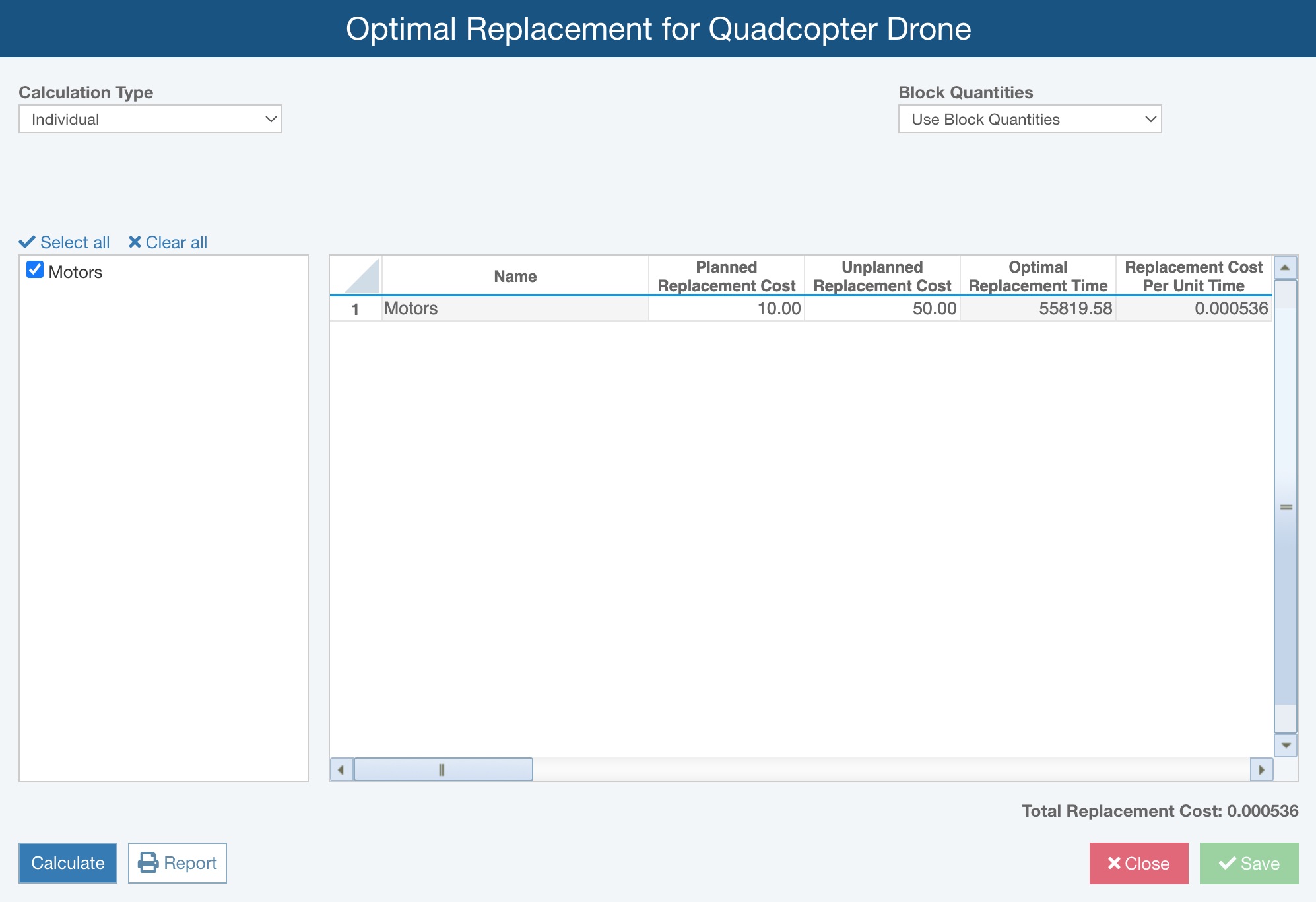

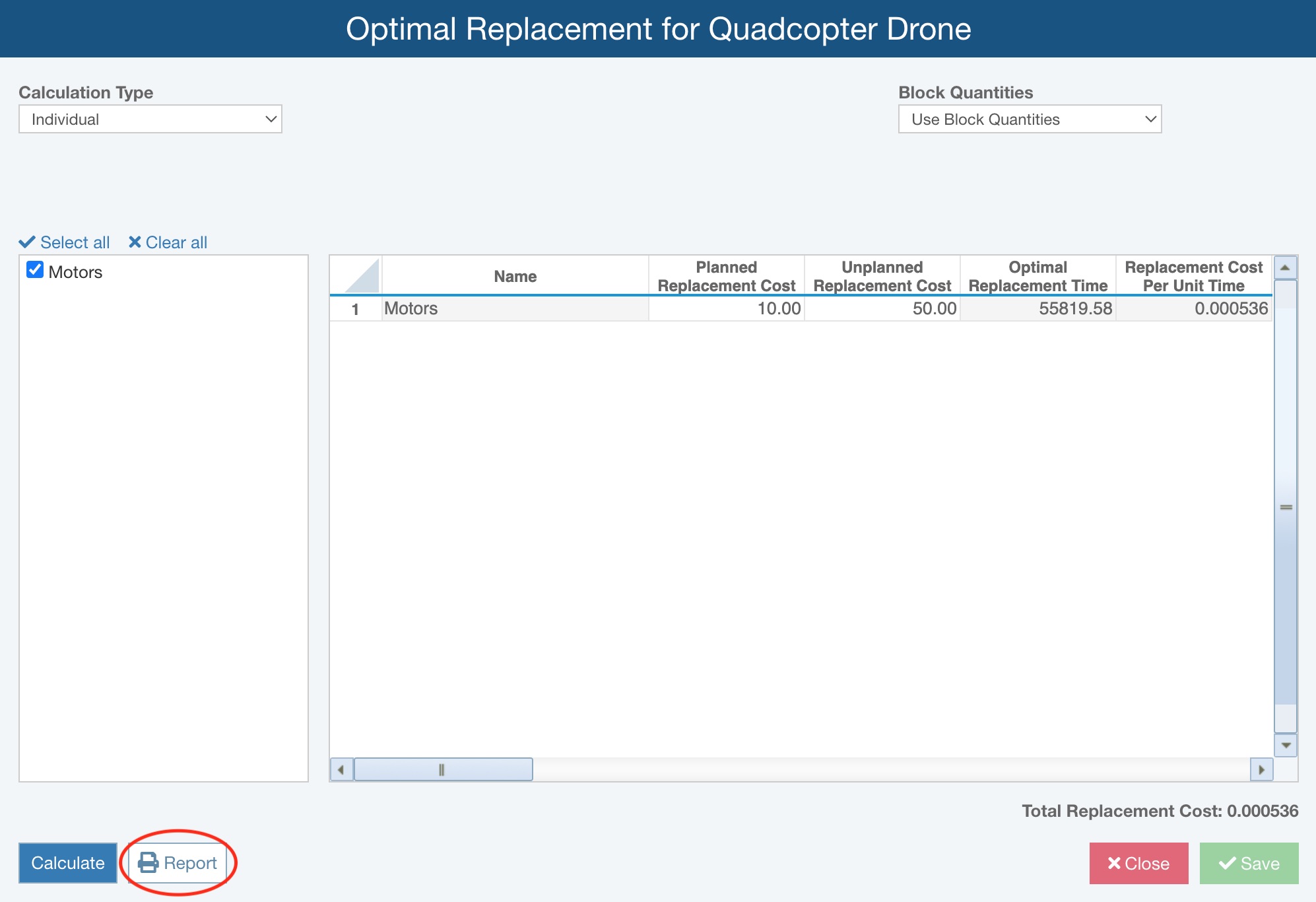

The Optimal Replacement dialog appears for the selected RBD, including the default or previous selections and results.

Establish the parameters for your optimal replacement analysis including the following:

- Calculation Type: methods to group blocks for calculations

- Individual: each selected block's optimal replacement time is calculated individually at its most cost-effective time

- Common: all selected blocks will have the same shared replacement time

- Clusters: selected blocks are grouped into clusters, where each cluster will have a replacement time for all blocks in that cluster

- Cluster By: options for how blocks are grouped into clusters

- Replacement Time: clusters are calculated to ensure that blocks with similar replacement times are grouped together in the same cluster

- Total Replacement Cost: clusters are calculated to minimize the overall replacement cost of all selected components

- Clusters: the number of clusters into which the blocks will be grouped

- Cluster By: options for how blocks are grouped into clusters

- Block Quantities: option to specify how to use block quantity values when performing optimal replacement calculations

- Use Block Quantities: quantity values assigned to blocks in the RBD are used

- Force Block Quantities to One: assumes quantity value for all blocks is 1

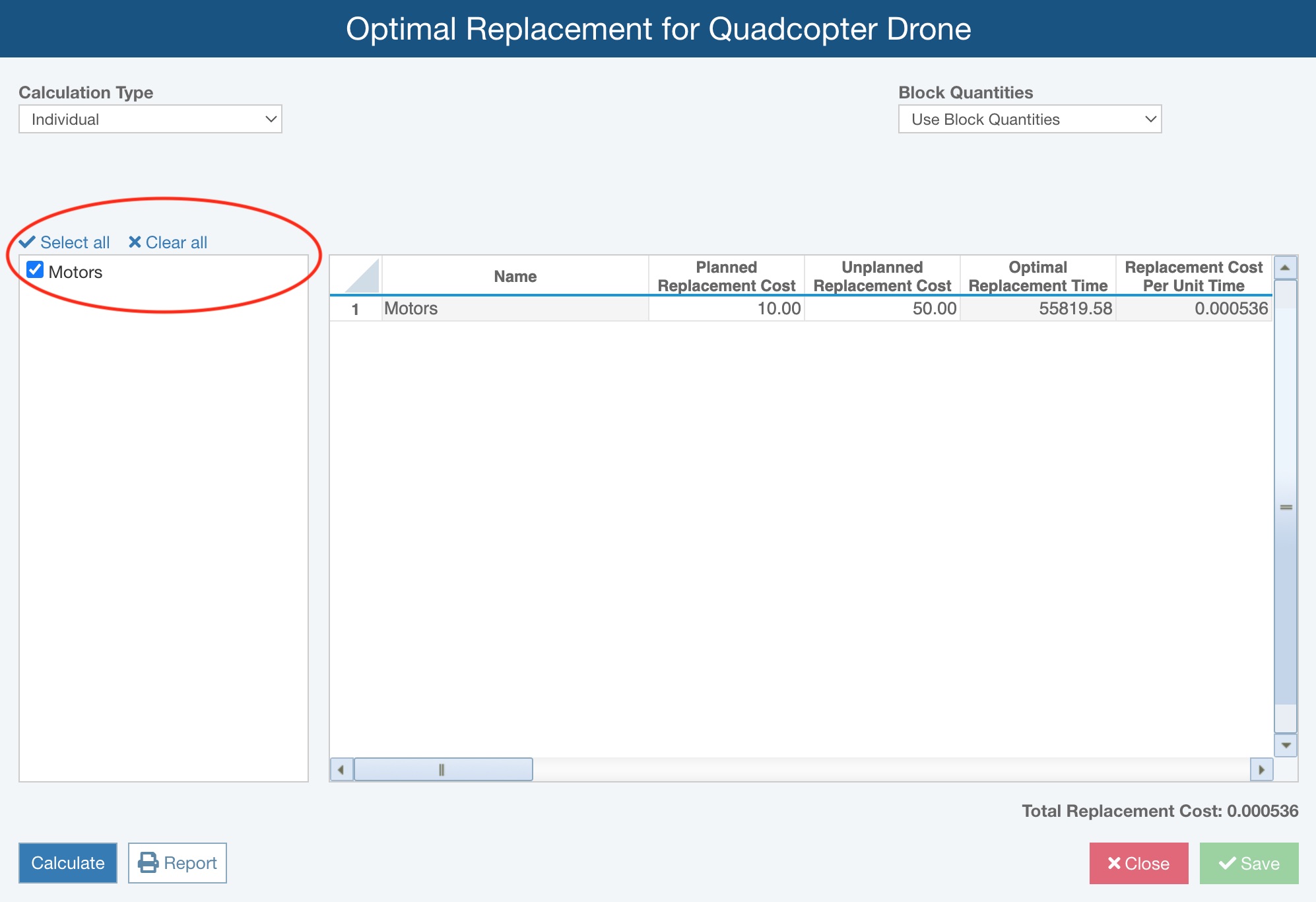

Then, select which blocks from your RBD you want to consider for optimal replacement.

To be eligible for inclusion in optimal replacement calculations, blocks must meet certain criteria:

To be eligible for inclusion in optimal replacement calculations, blocks must meet certain criteria:

- Unplanned, or corrective maintenance, costs must exceed planned, or preventive, maintenance costs

- Blocks must have a failure rate that increases over time

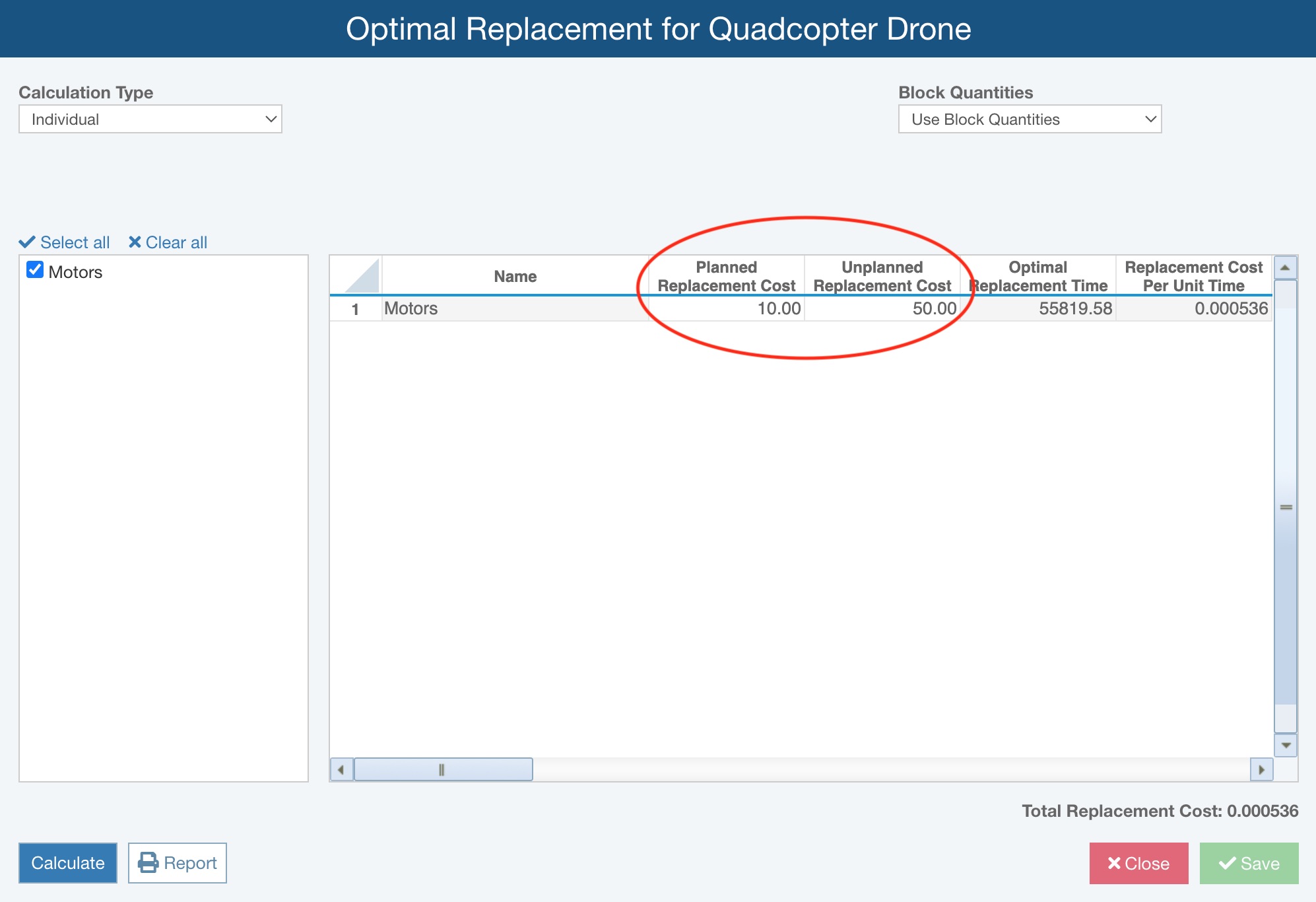

In the table, assign cost parameters, including:

- Planned Replacement Cost: cost associated with a planned replacement of this block

- Unplanned Replacement Cost: cost associated with an unplanned replacement of this block

Click Calculate.

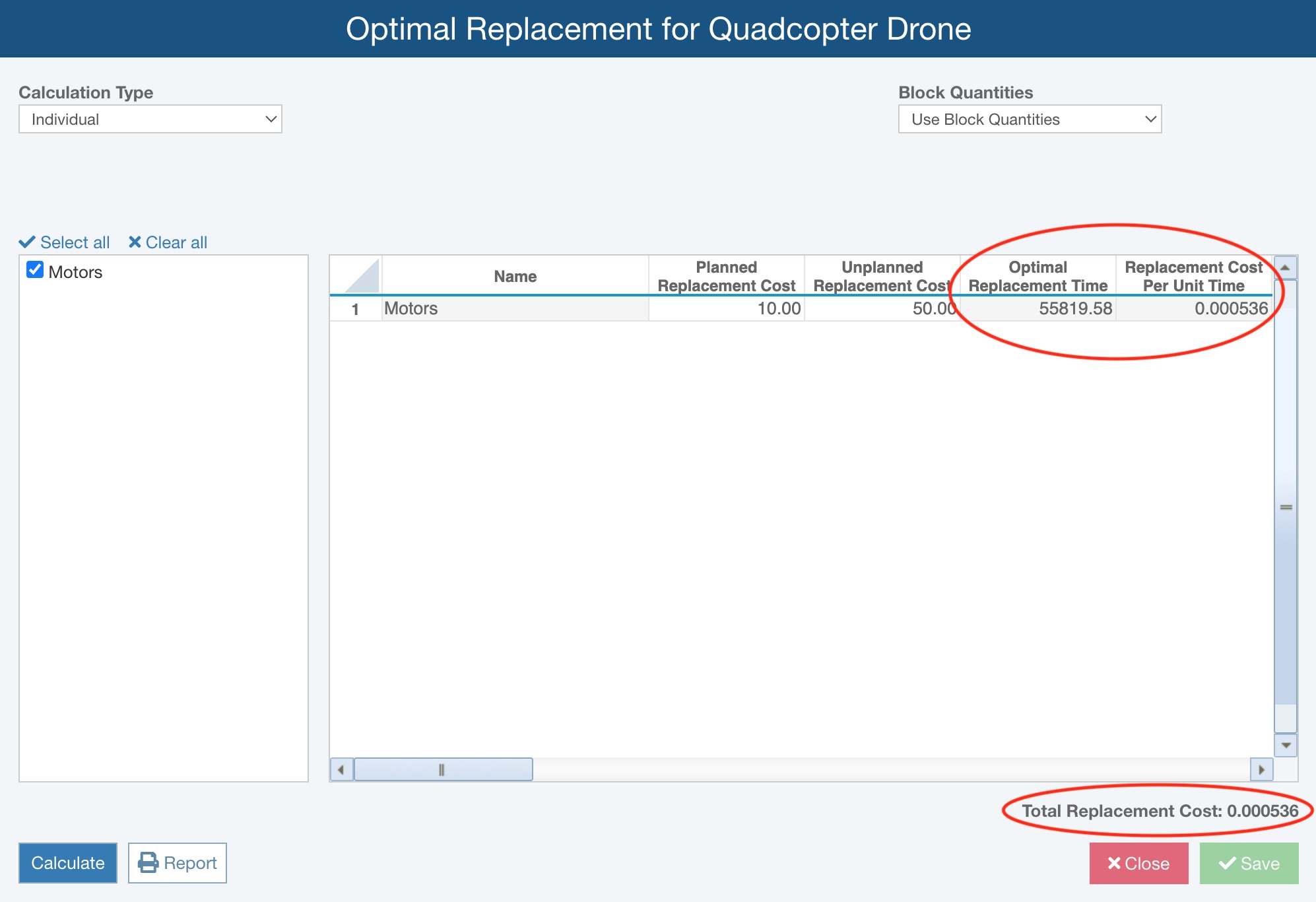

The optimal replacement analysis is performed and when complete, is noted by the green pop-up message in the bottom right corner, and then the results of the optimal replacement analysis appear in the table for each block.

The optimal replacement analysis results include:

- Optimal Replacement Time: the ideal time at which to replace the block

- Replacement Cost Per Unit Time: cost to maintain the component per unit time; it factors in planned replacement cost, unplanned replacement cost, and component reliability

- Total Replacement Cost: total replacement cost of all blocks considered for optimal replacement

Using the Report button, you can also generate a report including the optimal replacement analysis results.

After clicking Report, the Report Options dialog appears.

Enter a Report Title and click Report. The Optimal Replacement report appears in a new browser tab.

Close the browser tab to exit the report preview and return to Relyence.

When you have completed your optimal replacement analysis, use the Save and/or Close buttons to save the inputs if you prefer and close the Optimal Replacement dialog.