Using Allocations

When developing a new product, most often, an overall reliability goal is established. Allocations enable you to determine how to best distribute that reliability goal over all the subsystems in your product. There are various established methods for allocating failure rate, MTBF, or reliability across your system. You can select the method that best fits your requirements.

The following procedure outlines how to perform an Allocation analysis in Relyence Reliability Prediction.

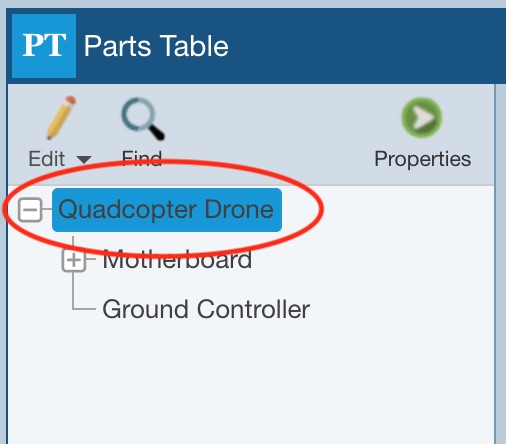

1. Select the Subsystem to be analyzed

First, make sure Relyence Reliability Prediction is active by clicking Reliability Prediction in the Sidebar menu if needed.

Select the Subsystem in your Analysis Tree for which you want to perform allocations.

If you want to perform allocations for your entire product, select the top-level, otherwise, select the Subsystem desired.

For this example, we will allocate across our entire System.

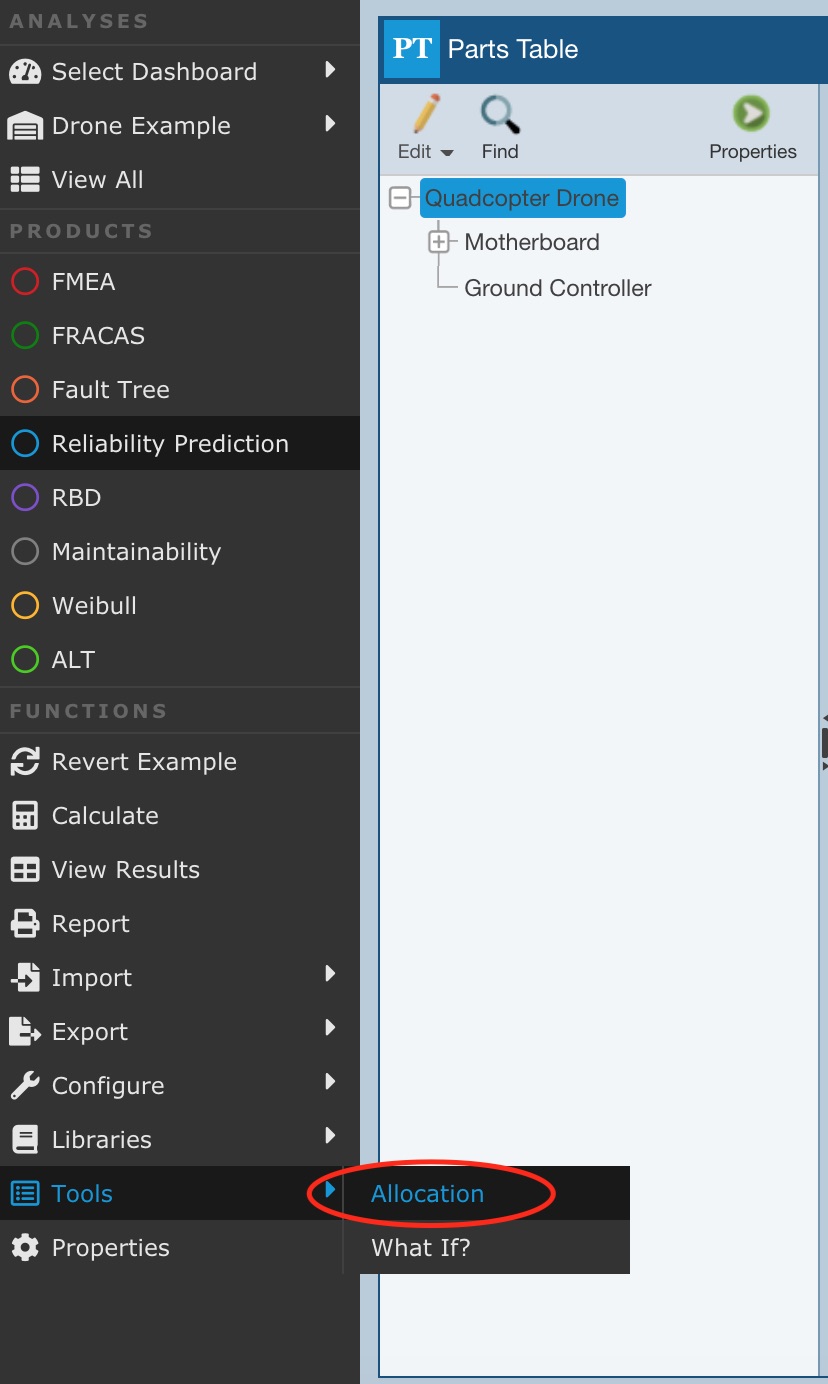

2. Select the Allocation Tool

Select Tools>Allocation from the Sidebar menu.

The Allocation dialog appears. Notice that the title of the dialog indicates the Subsystem for which you are performing allocations.

The current data and computed metrics from your Analysis are entered for a starting point for entering your parameters.

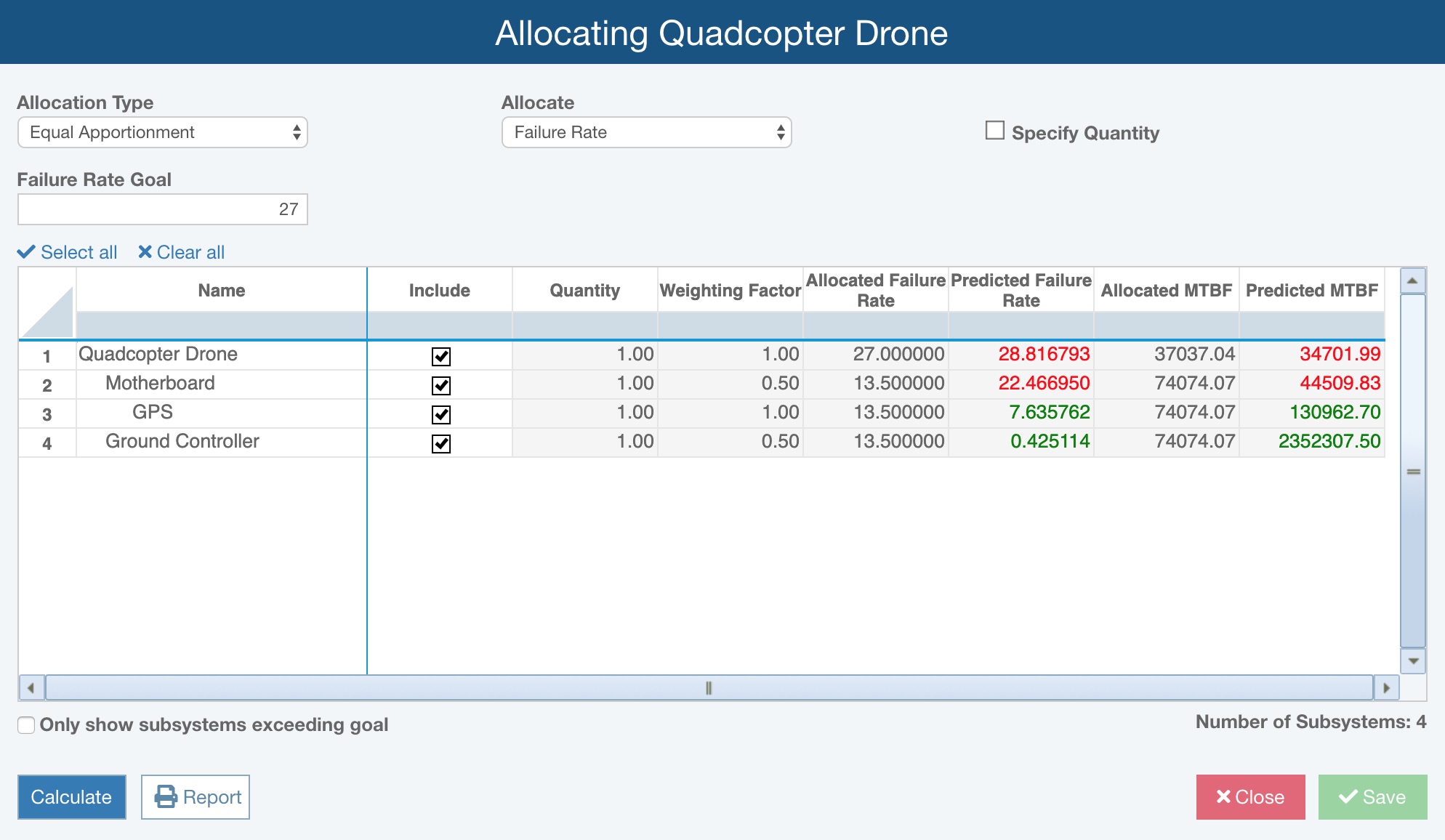

3. Set your Allocation parameters

Select the Allocation Method you want to use. You can choose from AGREE, ARINC, Equal Apportionment, Feasibility of Objectives, Repairable Systems, and Weighted. The parameters needed for analysis vary depending on the Method selected.

You can use the Select All and Clear All links, and the associated Include checkboxes to specify which Subsystems to use in the Allocation analysis.

To save your data at any time, click the Save button.

Allocation Methods and Data Parameters

- AGREE: The Advisory Group on Reliability of Electronic Equipment (AGREE) developed this allocation method. An Importance Factor is used as the basis for the weight factor for Allocation analysis. The Importance Factor accounts for the complexity of each Subsystem (based on number of components in the Subsystem), and its overall importance to the System.

- Enter your Reliability Goal and Mission Time.

- Select Specify Number of Parts to enter the number of Parts in each Subsystem, otherwise leave it clear to use the number of Parts in the Subsystems in your Analysis.

- Enter the Mission Time and Importance Factor for each Subsystem enabled for Allocation analysis.

- ARINC: The failure rate of each Subsystem is entered and used to determine the weighting factor for Allocation analysis. Typically, the predicted failure rates are used, but specified values can be entered. The allocation goal is distributed across Subsystems based on their associated portion of the overall predicted failure rate.

- Select the metric to use to Allocate: Failure Rate, MTBF, or Reliability.

- Enter the Failure Rate Goal, MTBF Goal, or Reliability Goal.

- Enter the Mission Time if Reliability is the selected metric to allocate.

- Select Specify Failure Rate if you want to enter the Failure Rate for your Subsystems, or clear it to use the default predicted values.

- Equal Apportionment: The goal is distributed equally across all Subsystems, therefore no weight factors are required. This allocation method is non-recursive.

- Select the metric to use to Allocate: Failure Rate, MTBF, or Reliability.

- Enter the Failure Rate Goal, MTBF Goal, or Reliability Goal.

- Enter the Mission Time if Reliability is the selected metric to allocate.

- Select Specify Quantity if you want to enter the Quantity of Subsystems, or clear it to use the default values from your Analysis.

- Feasibility of Objectives: The weight factors for allocation are determined based on four rating values (Intricacy, State of the Art, Performance, Environment), each set between 1-10 for each Subsystem.

- Select the metric to use to Allocate: Failure Rate, MTBF, or Reliability.

- Enter the Failure Rate Goal, MTBF Goal, or Reliability Goal.

- Enter the following for each Subsystem enabled for Allocation analysis:

- Intricacy - based on the number of Parts or complexity of the Subsystem. 1 is simple, 10 is complex.

- State of the Art - how advanced the technology is. 1 is mature, 10 is new technology.

- Performance - how long the Subsystem operates over the course of the Mission Time. 1 is low operating time, 10 is continuous operation over the mission

- Environment - the operating environment of the Subsystem. 1 is a benign environment, 10 is a severe environment.

- Repairable Systems: The Availability goal is distributed across all Subsystems using MTTR values as a weighting factor.

- Enter the Availability Goal.

- Enter the MTTR for each Subsystem enabled for Allocation analysis.

- Weighted: The goal is distributed equally across all Subsystems based on the weight factor entered.

- Select the metric to use to Allocate: Failure Rate or MTBF.

- Enter the Failure Rate Goal or MTBF Goal.

- Enter the Weight factor to use for each Subsystem enabled for Allocation analysis.

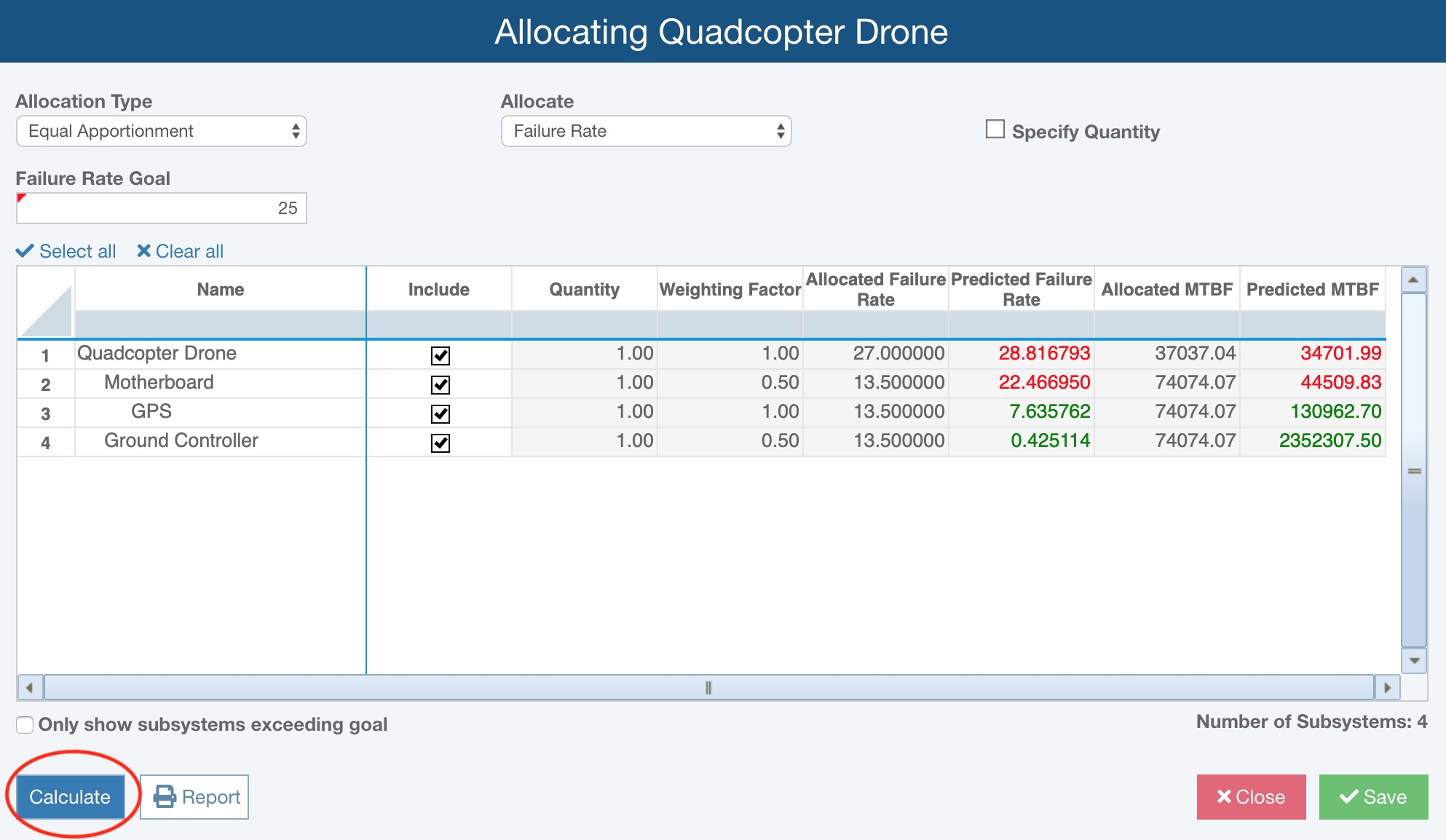

4. Perform the Allocation analysis

Once you have entered your allocation information, click the Calculate button to perform the analysis. Any unsaved data entered will be automatically saved, and the analysis will proceed.

The results will appear in the Allocation Table.

The resulting allocated values are shown compared to their associated predicted values.

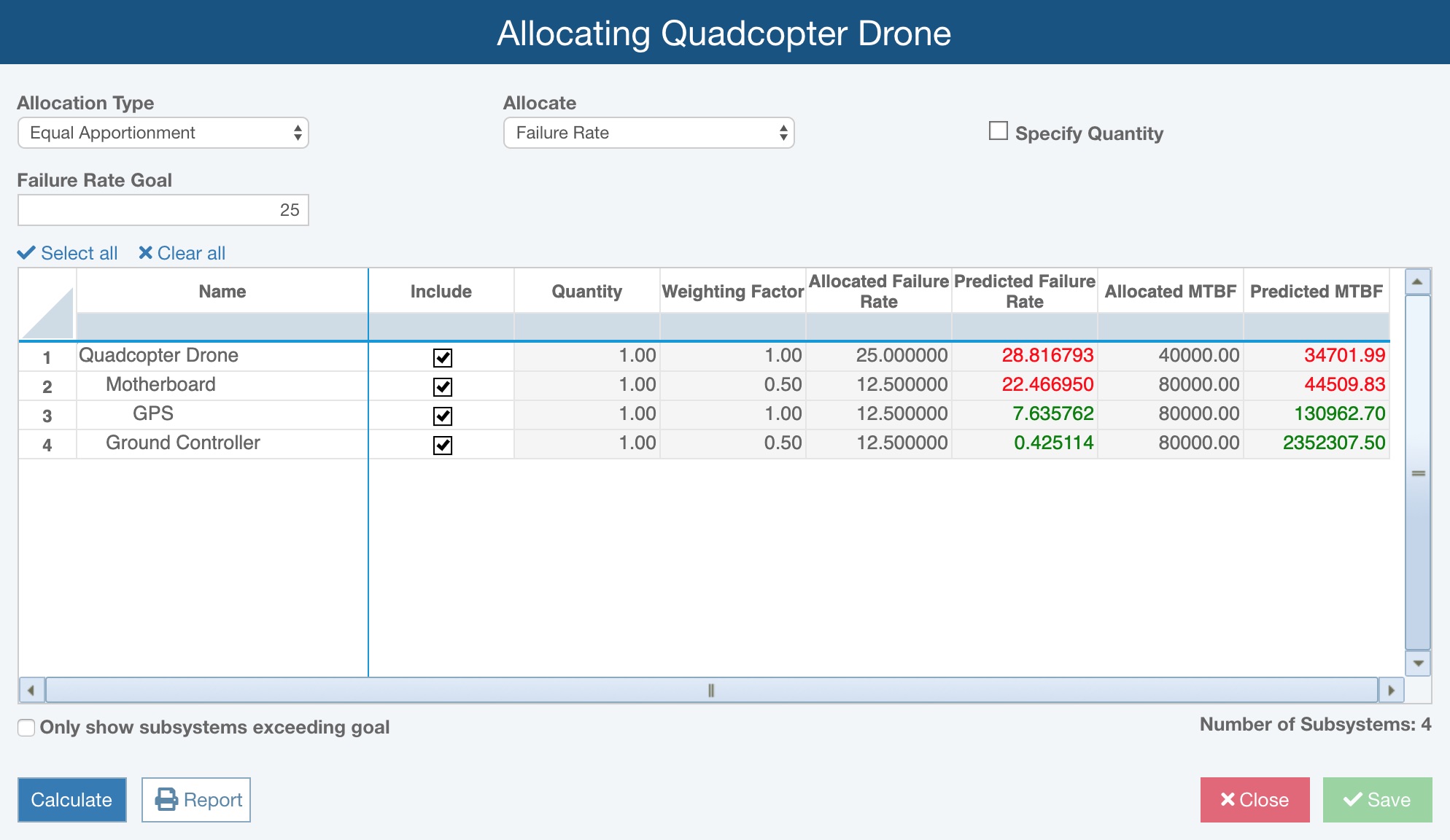

As an example, our Quadcopter Drone has a predicted failure rate of about 28 FPMH. However, suppose our Failure Rate Goal is actually 25 FMPH and we want to allocate that goal equally across all Subsystems of the Quadcopter Drone. In this case, for the Allocate parameter, select Failure Rate and enter 25 as the Failure Rate Goal.

In this simple example, shown in the screenshot above, you can see our Failure Rate Goal of 25 was equally distributed across the two Subsystems in our Quadcopter Drone: the Motherboard and Ground Controller each have an Allocated Failure Rate of 12.5 FPMH. The 12.5 FPMH allocated to the Motherboard is allocated to its single GPS Subsystem.

If you only want to see the Subsystems that exceed their allocated goals compared to their predicted metrics, select the Only show subsystems exceeding goal checkbox. Otherwise, clear it to show results for all Subsystems.

In this example shown above, if Only show subsystems exceeding goal is selected, the Ground Controller and GPS are not shown because their predicted Failure Rates are lower than the Allocated Failure Rates.

As another example, suppose I wanted to allocate the 25 FPMH goal across the Quadcopter Drone, but allow the Motherboard to have a double portion of the total goal compared to the Ground Controller. In this case, set Allocate to Weighted, and enter a Weight of 2 for the Motherboard and leave the other Weights as 1. The results will show an allocated Failure Rate of 16.67 FPMH for the Motherboard, and 8.33 FPMH for the Ground Controller.

5. Generate an Allocation report

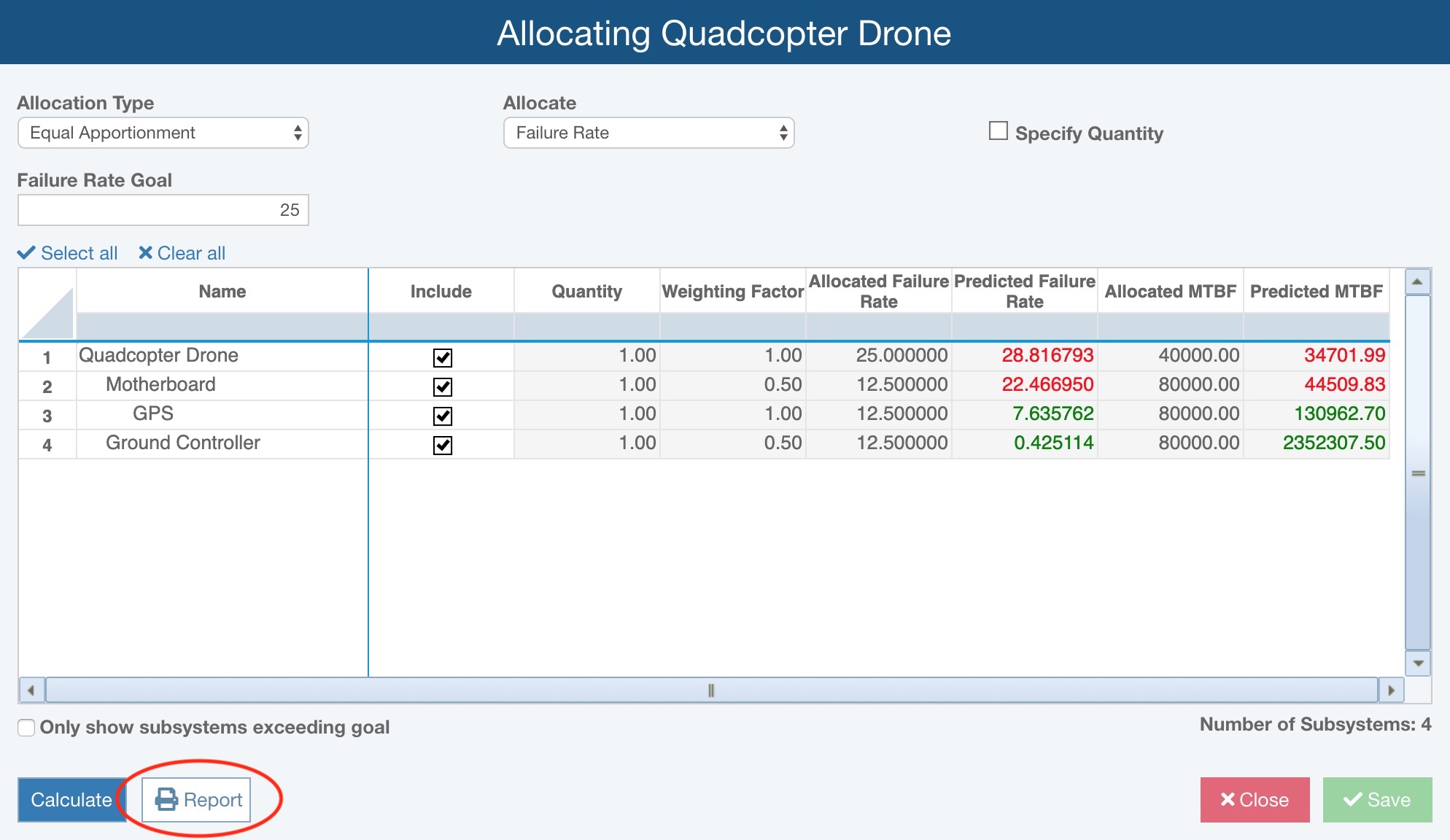

To generate a report of your Allocation analysis, click the Report button.

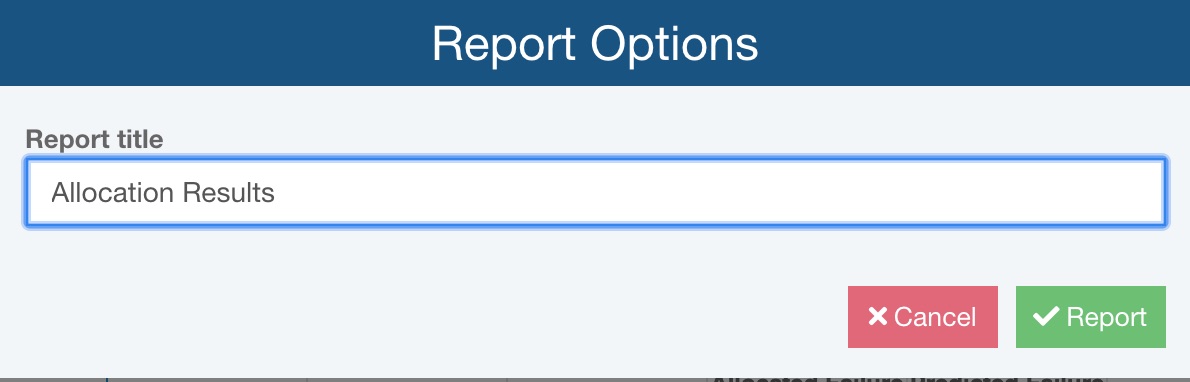

The Report Options dialog appears.

Enter a Report title for your report. Click the Report button to generate the report.

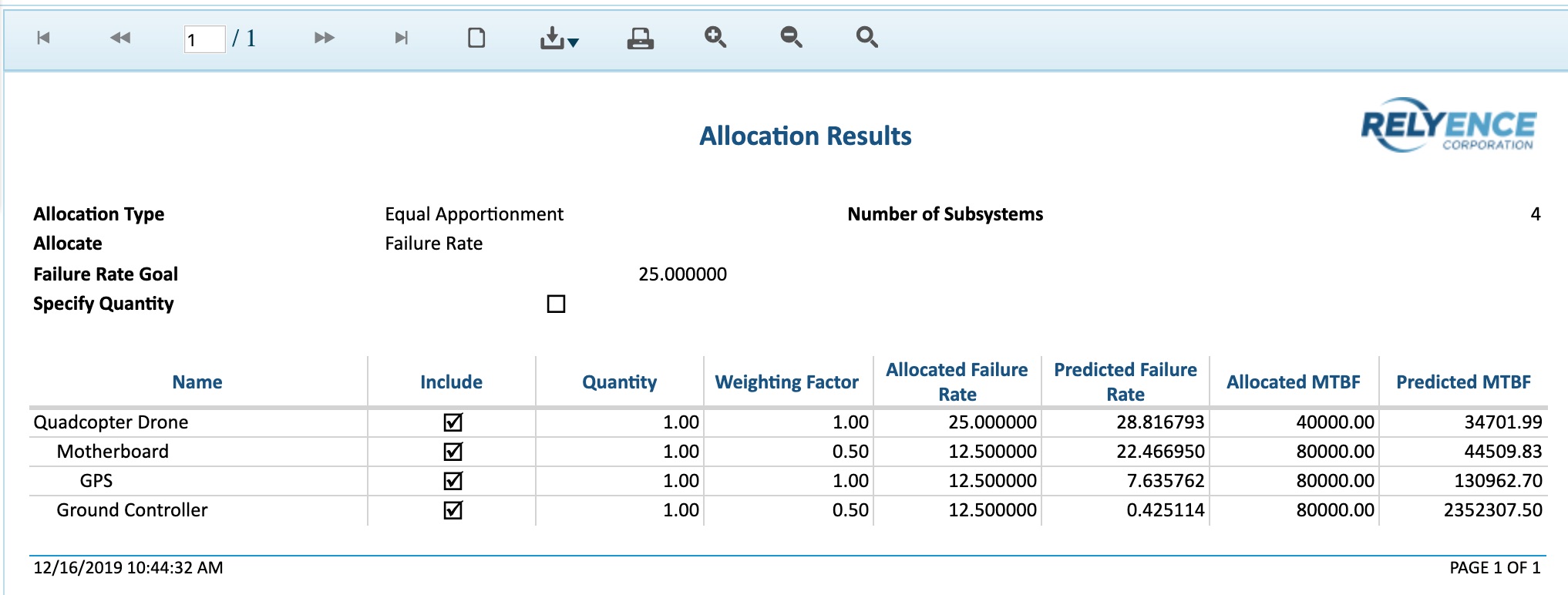

The report appears in a new browser window.

You can print your report, or download it to a PDF, Excel, PowerPoint, TIFF, or Word document.

Close the report browser window when you have completed viewing the report.

Click Close when you are finished performing the allocation analysis.