Reliability Prediction analysis is one of the core techniques used in the reliability engineering field. So, what exactly are Reliability Predictions? What is Reliability Prediction software? Why are Reliability Predictions done? This article will review the fundamentals of reliability predictions to help answer some of these central questions.

What are Reliability Predictions?

Reliability Predictions are one of the most widely used techniques in reliability analysis. The core function of a reliability prediction is to evaluate an electro-mechanical system to estimate or predict its failure rate. The methods used to assess failure rate are described in reliability prediction standards. Reliability prediction standards have a long history in the reliability engineering field.

Reliability engineering has roots from long ago, but the 1950s saw key work being done throughout military and commercial groups, including the Department of Defense, NASA, and other industries. Looking back at the history of reliability engineering, the decade of 1960’s was key in the evolution of the field. Along with other notable events, the initial release of MIL-HDBK-217 occurred. This standard remains as one of the most widely used and accepted reliability prediction standards in use today. There are number of additional reliability prediction standards currently used, including Telcordia (formerly Bellcore), 217Plus, IEC 61709, SN 29500, and China’s GJB/z 299.

The basis of reliability prediction standards is statistical analysis of a wide range of component data gathered in the field over a long time period. This data is then analyzed to develop a series of equations that can be used to model the underlying failure characteristics of devices. The equations developed include a number of variables that affect reliability, such as operating environments, temperatures, quality levels, and stress factors.

To perform a reliability prediction, you begin by listing all the components in your system design. You then compute the estimated failure rates of your components using the equations from the standard you choose to use. The summation of all the components’ failure rates is the predicted failure rate of your system.

How Reliability Prediction Failure Rates are Calculated Using Equations

To delve more deeply into the details of reliability prediction standards, it is helpful to look at an equation for a specific component type. For example, the equation for modeling the failure rate of Microcircuits, Gate/Logic Array and Microprocessors from the widely used MIL-HDBK-217 standard is:

λp = (C1 * πT + C2 * πE) * πQ * πL

where λp is the failure rate in failures/million hours (or failures/1,000,000 hours, or FPMH)

The factors in the equation are various operating, rated, temperature, and environmental conditions of the device in the system. For the above equation, the following list describes the variables:

- C1 factors in the complexity of the device, such as the number of gates or transistors

- πT factors in the ambient temperature and any temperature rise associated with the device

- C2 factors in the package of the device, or how it is manufactured and placed in the system, such as surface mounted and/or hermetically sealed

- πE factors in the environment that the device is operating in, such as in space, in an aircraft, in the sea, on the ground, etc.

- πQ factors in the quality of the device based on how it is procured

- πL factors in how long the device has been manufactured

The equations, the variables, and the data parameters needed vary across device types. Also, the failure rate models differ across the various standards.

Example Reliability Prediction Failure Rate Calculation

So, for example if one of my components is a hermetically sealed, quad 2-input NAND gate with 14 pins, has been in field use for many years, is operating in a typical “ground” environment at 30 degrees C, and is procured at commercial level quality, I can evaluate its failure rate using the example above. Using the MIL-HDBK-217 standard, I evaluate the contributing elements, referred to as pi factors:

- C1 = .0025

- πT = 0.137893

- C2 = .004841

- πE = 0.5

- πQ = 10.0

- πL = 1.0

The resulting failure rate, λp = (.0025 * 0.137893 + .004841 * 0.5) * 10.0 * 1.0, or 0.027655. This indicates that this part is estimated to fail 0.027655 times over a million hours. Failure rate units when using MIL-HDBK-217 are typically expressed in failures/million hours. Other units of measure are also used in reliability predictions. Another common one is FIT, which stands for Failures In Time, or failures/billion hours. FIT is commonly used in the Telcordia standard.

What is the Bathtub Curve?

To understand some of the foundation behind the reliability predictions standards, a discussion of the bathtub curve is helpful.

The bathtub curve is a graphical representation of failure characteristics of components over their lifetime. The name is derived from the shape of the curve, which looks like a bathtub when shown plotted on a time axis:

- A descending curve in the first part of the graph

- A flat area in the central part of the graph

- An ascending curve in the last part of the graph

The first section indicates early failures, or infant mortality failures – those failures that occur during product release or introduction.

The center section indicates the longest time frame – during the useful life phase of the product. In this time frame, product failures tend to be random, and occur at more or less a constant rate.

The final section indicates the end of the product lifecycle – when wear out failures occur.

In general, many products follow the bathtub curve through their lifecycle. Early failures are addressed by fixing defects. Then, the product remains in operation for a long time with a random, but low and constant failure rate. Lastly, if the product remains in use after a long time period, age will take its toll and the wear out failures occur.

Reliability Predictions are used to estimate the failure rate of products in the constant failure rate portion of the bathtub curve. Some standards include additional factors to address the early life and wear out portions of the bathtub curve. These values can be used in addition to the constant failure rate predictions for additional product assessment if desired.

What is Reliability Prediction software?

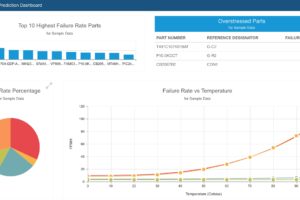

From the prior example, you can see how performing a reliability prediction analysis manually can be tedious and error prone. Also, you can see how a simple change, such as a temperature change, would ripple through the analysis and require a complete recalculation. For this reason, reliability prediction software packages are typically used to perform reliability prediction analysis.

Reliability Prediction software automates the computational tasks, and also provides a wealth of additional features to make reliability analysis more effective and comprehensive.

Why are Reliability Predictions done?

Reliability Predictions can be done at any phase of the product lifecycle, but are most commonly used during the product design stage. During this time, it is helpful to use reliability predictions to evaluate your proposed design for reliability concerns. If reliability issues can be addressed early on, and especially prior to manufacturing, the cost savings are significant.

Reliability Predictions can be used at any other point in the product lifecycle: during prototyping, testing, manufacturing, and deployment. Essentially, any time when you would like a more in-depth review of the reliability of your product, reliability predictions are a useful tool for that purpose.

Armed with a reliability profile of your product, this knowledge can then be used to assess, improve, and track the reliability of your product or system. You can see how the information from a reliability prediction assessment can be used to further your reliability improvement objectives, including:

- Helping to assess the feasibility of a proposed design

- Comparing design alternatives for the most reliable option

- Identifying potential reliability areas of concern

- Performing What-If? analyses to determine the effects of specific design modifications

- Tracking reliability improvement

- Addressing product quality issues in early design before they become problematic

- Decreasing the Cost of Poor Quality (COPQ)

- Meeting contractual compliance requirements

By using reliability predictions as part of your overall reliability program, you can proactively address reliability issues. This enables you to ensure your products meet your reliability and quality requirements, and keep your continual improvement goals at the forefront of your organization.