Of all major industries, the oil and gas industry requires more predictability than any other to ensure its workers, consumers, and profit margins are sufficiently protected from equipment-related and human-induced failures. From catastrophic offshore oil rig disasters to the recent over-pressurized gas line ruptures and the subsequent explosions that ripped through multiple neighborhoods in Massachusetts, the oil and gas industry suffers more than profit losses when it fails to predict, analyze, and correct oil and gas equipment failures.

Fortunately, for everything from reliability prediction of offshore equipment to RAM analysis of production facilities, Relyence has the reliability and failure analysis products to help businesses throughout the industry maintain reliable, top-quality operations.

Oil & Gas Industry Professionals Consistently Recognize the Need for Reliability

Oil and gas producers know that reliability in operations is required to maintain production level requirements, to prevent unscheduled maintenance and repair work, as well as to avoid costly accidents and to prevent environmental damage.

Not only is safety a top concern for workers, consumers, and the community, but oil and gas professionals recognize that safety and reliability are intertwined and vitally important. And that both directly impact not only profitability, but also company standing and reputation.

Reliability Analysis Tools for Oil & Gas Companies

The oil and gas industry has a host of products available at their fingertips to make sure workers are kept safe and businesses comply with specific industry standards. Relyence offers many oil and gas reliability software tools to conduct better analysis of daily operations:

- Relyence FMEA (Failure Mode & Effects Analysis): Since oil refineries are such hazardous workspaces, effective risk analysis is needed to reduce the risk of harm to workers and the surrounding environment. Relyence FMEA breaks down failure modes into a risk profile, so organizations can then determine how to best eliminate the harmful effects of those failures.

- Relyence FRACAS (Failure Reporting, Analysis & Corrective Action System): This software records a business’ entire Corrective and Preventive Action (CAPA) process. Using Relyence FRACAS/CAPA, you can systematically view every issue reported at your refinery, so you can ensure no incident goes unresolved.

- Relyence Fault Tree Analysis: Relyence Fault Tree allows you to assess the likelihood of high-risk events that could affect your business operations and your customers. By determining the possibility of failures, you can decide how to best improve your business processes to reduce the chance of these complications.

- Relyence RCM (Reliability Centered Maintenance): Uptime, or availability, is of vital importance in the oil and gas sector. Repairs need to be managed efficiently to minimize downtime. Preventive maintenance is key to avoiding unexpected and costly failures. However, preventive maintenance needs to be done judiciously to avoid excessive costs and unnecessary use. Reliability Centered Maintenance analysis offers the most valuable approach to balancing all these objectives. Providing a platform to optimally develop your repair and maintenance strategies, RCM is an important tool in your RAM software platform.

- Relyence Maintainability Prediction: One of the most significant challenges facing the oil and gas industry today is optimizing performance for simplicity and dependability. With Relyence Maintainability Prediction software, you’ll view statistics specific to your maintenance and repair metrics. You can then determine how to maximize your maintenance procedures and facility uptime.

- Relyence RBD (Reliability Block Diagram): Oil and gas companies must constantly assess their underground pipelines’ reliability to ensure the substance can travel to its destination without leakage. Relyence RBD can track this reliability in each pipeline segment using diagrams and proven analytical techniques.

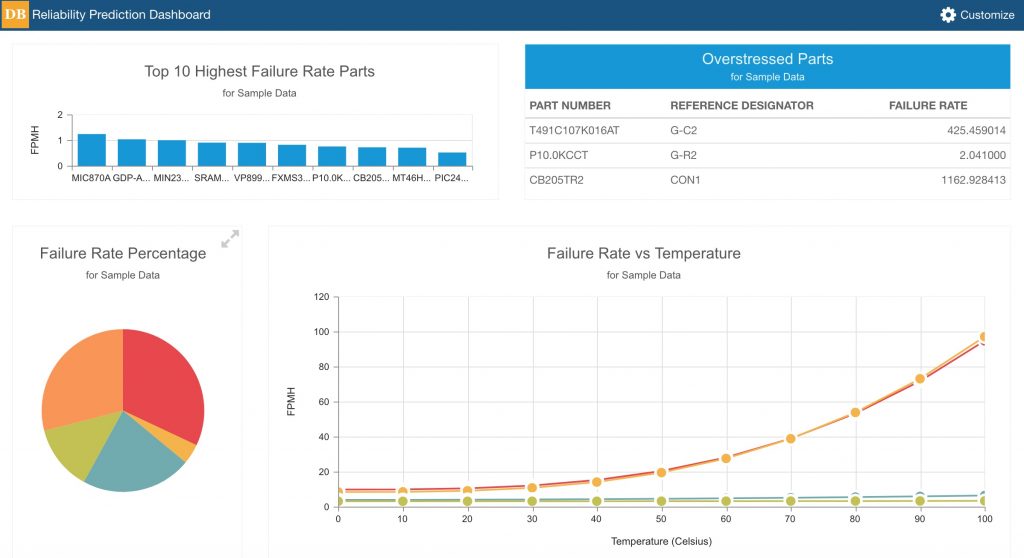

- Relyence Reliability Prediction: This cutting-edge tool helps reliability engineers and quality control managers more quickly and accurately predict instances of potential failure in the equipment, components, systems, processes, and services that the industry relies on to safely and efficiently serve consumers’ energy needs.

- Relyence Weibull: Relyence Weibull allows users to monitor product trends and predict when and how often a product will fail. This software is particularly useful in monitoring pump problems and pipeline failures.

- Relyence ALT: Relyence ALT allows users to effectively analyze data obtained during accelerated life testing. This analysis tool is key to assess component reliability when accelerated life testing is employed in order to assess performance using high stress conditions.

Reliability Standards and Requirements for Oil & Gas Producers

Several organizations set standards in the ongoing attempt to enhance reliability and safety in the oil and gas industry. From the American Petroleum Institute (API) to the International Association of Oil & Gas Producers (IOGP), the industry does a great deal to promote best practices and share advancements in the occupational safety of its workers.

When performing reliability analysis, taking industry standards and requirements into account is vital. In the oil and gas industry, some of the most important standards to consider include:

- ISO standards: The International Organization for Standardization, or ISO, issues hundreds of standards for the oil and gas industry. These standards provide guidance for everything from safety procedures to drilling equipment, and several impact reliability modeling, data, and design.

- API standards: API has more than 700 standards created to improve operational safety, sustainability, and environmental safety in the American oil and natural gas industry. Their standards also keep costs down and ensure product quality. Following API reliability standards is becoming increasingly important as they are adopted by a growing number of international regulators.

- Other international standards: International standards, such as those set by the IOGP, are particularly influential for companies engaged in offshore drilling. IOGP standards aim to improve safety, reduce environmental impact, and prevent damaging and potentially dangerous failures. However, in the absence of international standards, companies must still obey national and regional requirements.

Relyence reliability analysis software is designed for maximum compatibility with all oil and gas industry standards and requirements. The Relyence software tool is even capable of considering multiple standards in one analysis, so you’re able to produce customized reliability models that meet your organization’s specialized needs.

The Benefits of Using Relyence as Part of Your Reliability Toolset

For streamlined equipment, systems, and services reliability analysis, Relyence software comes complete with the following features and benefits:

- Rapid data entry: Thanks to a modern, intuitive user interface and customized default settings, Relyence reliability software allows you to enter data quickly and gain the risk insights your oil or gas business needs.

- Full system modeling: From drilling to production, oil and gas extraction is a complex process that is reliant on a number of connected systems. Relyence software manages this complexity using full system modeling, including visual block diagrams and mission profile calculations, to ensure accurate, useful results.

- A highly accurate calculation engine: Relyence software couples a simple user interface with a powerful and highly accurate back-end calculation engine. Our software takes all the factors that influence oil rig reliability analysis into account.

- A mobile-friendly platform: You can access Relyence software through your browser or mobile device. Our tools can be installed on-premise or hosted in a public or private cloud, depending on the level of security and flexibility your company requires.

- Trade-off analyses: With Relyence software, you can complete rapid “What If” trade-off analyses for quick assessments of design alternatives. This enables you to make data-backed decisions to improve or preserve the productivity of your oil or gas production.

- Easy integration: Oil and gas operations may have a variety of analysis tools aimed at evaluating failure and preventing future risk. All of Relyence’s analysis tools, including those for Reliability Prediction, FRACAS, and RBD, are designed to share data and work together to perform optimal analyses.

Plus, the complete Relyence suite of reliability and analysis tools is supported by our dedicated technical and training specialists. With Relyence, you’re assured of having a trusted partner in your business’s reliability prediction and quality control.

What to Look for in Oil and Gas Reliability Software

As oil and gas companies tackle challenges like resource shortages, operational difficulties, and technical risks, the need for accurate reliability software has grown significantly. As you search for the best reliability analysis tools, look for a product — like the Relyence Studio — that contains the following features:

- Core capabilities: The software you choose must be able to perform the core analysis functions you require — for example, incorporating compliance standards and completing calculations accurately and efficiently.

- Full suite: It’s wise to purchase reliability analysis software from a provider that offers a full suite. This gives your oil and gas company the tools and integration capability it will need to assess risk and maintain compliance, even as the business expands and evolves over time.

- Flexibility and customization: Your reliability analysis software should allow you to work how you want. The ability to customize your software and choose between on-premise and cloud installation gives you the flexibility you require.

- Ease-of-use: Reliability analysis software should give an oil and gas company the ability to gain critical insights quickly. The ideal tool is easy to use and automates the process of calculating reliability and quality-based metrics.

- Up-to-date technology: Ensure your software is prepared for the future by selecting a system built on up-to-date technology, including browser access and support for mobile devices.

- Continual product improvement: Finally, look for an oil and gas reliability software provider dedicated to continual product improvement. Find a team that can provide responsive technical support and that values customer suggestions for improvement.

What Our Customers Say About Us

Subscribe to Our eNewsletter

In addition to providing top-notch products, our dedication to delivering an outstanding customer experience is unparalleled. That’s why we encourage you to reach out to us with questions. And, please subscribe to out eNewsletter to keep up-to-date with what’s happening in quality and reliability in the oil & gas sector.

Relyence Advisor: Tools & Tips for the Reliability and Quality Professional

Note: You can unsubscribe at any time.

Request a Free, No-Obligation Trial

In addition to providing superior products, we also deliver an outstanding customer experience. That’s why we encourage you to contact us with any questions; sign up for a free, no obligation-trial; or request a free quote today. Remember: Relyence is committed to helping you meet your reliability goals.