This article is an excerpt from our “How to Assess Risk Using FMEA” white paper.

FMEA, or Failure Mode and Effects Analysis, is a widely adopted approach for failure analysis and risk assessment. Originating in the 1940s for use in the U.S. military, FMEA is now one of the most commonly used techniques in engineering for failure analysis of products and processes. FMEA is an organized, step-by-step process for comprehensively evaluating a system or process to identify potential failure modes and eliminate or mitigate those deemed most critical.

The FMEA process begins by identifying all possible failure modes of a product or process. The second step is to determine the possible causes and resulting effects of those potential failures. You then assess the risk level associated with each of the failure modes based on a set of established criteria. Finally, you find ways to detect, mitigate, or prevent failures in order to bring your product or process into alignment with your overall quality and risk goals.

Our New to FMEA article is a helpful introductory overview of FMEA concepts.

FMEA Risk Assessment Strategy

While each step of the FMEA process is crucial for a successful analysis, the risk assessment element is key to zeroing in on the most risk sensitive areas that must be addressed in order to meet your quality and safety objectives. The risk assessment strategy you employ is vital in determining your action plan for product or process improvement. Essentially, ineffective risk assessment leads to an ineffective approach to risk reduction.

By utilizing a sound risk assessment strategy, you can easily determine the key areas to focus on for improvement. This ensures your team’s efforts will be focused on those failures that are most critical. By targeting the key areas of concern for risk mitigation tasks, you can be confident you will meet your overall reliability and safety objectives.

There are various ways to assess the risk of the failures identified during the FMEA process. Three of the most commonly used approaches for risk assessment are:

- RPN, or Risk Priority Number, defined in standards such as AIAG and SAE J1739

- AP, or Action Priority, as defined in the FMEA Handbook from AIAG & VDA

- Criticality as defined in MIL-STD-1629

To best suit their needs, organizations will choose to use one of the methods as defined in the handbooks, modify one of the methods, or create their own unique risk assessment method. By understanding the principles behind these assessment methodologies, you can decide which is the best approach for your organization.

Risk Assessment Factors

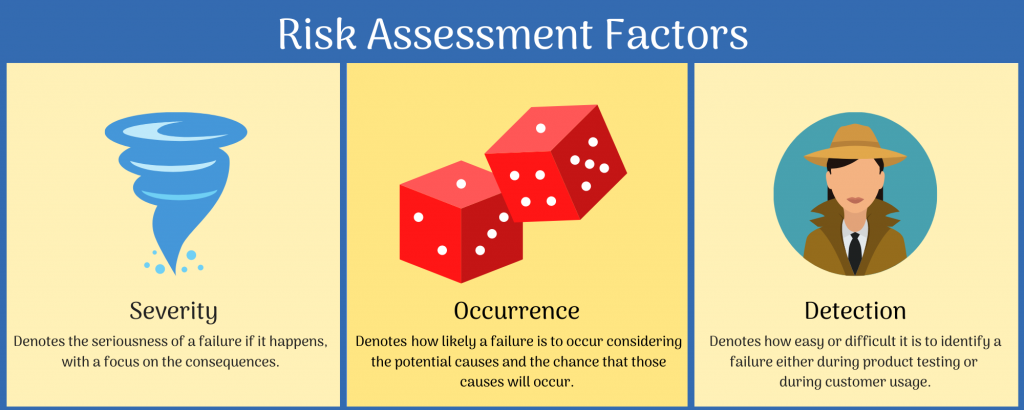

Three factors are often used to analyze the risk of the potential failures and resulting effects identified during FMEA:

- Severity: Denotes the seriousness of the problem if it happens, with a focus on the consequences. The higher the number, the greater the severity.

- Occurrence: Denotes how likely the issue is to occur. To determine the rate of occurrence, you’ll want to look at all the potential causes of a failure and the chance that those causes will occur. The higher the number, the greater the probability of occurrence.

- Detection: Denotes how easy or difficult it is to identify the problem. A higher rating means an issue is less likely to be detected either by engineers during the test phases of product development or by customers after product release. Therefore, the higher the number, the less likely the failure is detected.

Commonly used risk assessment factors: Severity, Occurrence, and Detection

There are Severity, Occurrence, and Detection scales provided in FMEA standards. However, organizations often customize the scales to better suit their needs.

For an in-depth look at the most commonly used risk assessment methodologies and examples of how they are used, download the white paper.

Learn More about FMEA Risk Assessment Methods

“How to Assess Risk Using FMEA” covers the following topics:

- FMEA: Failure Mode & Effect Analysis

- FMEA Risk Assessment Strategy

- Using RPN for Risk Assessment

- Example Using RPN

- Using the Risk Matrix

- Using AP for Risk Assessment

- Example Using AP

- Using Criticality for Risk Assessment

- Using the Criticality Matrix

- Example Using Criticality

- Using a Custom Risk Assessment Strategy

- Reassessing Risk After Recommended Actions Are Implemented

- Example Revised Risk Analysis

- Conclusion

Download the full white paper here. If you are interested in learning more about Relyence software, contact us or start your free trial today!