Today’s commercial enterprises depend more than ever before on the quality of their products and consequently on their reputation for manufacturing such high-quality products. As a result, the risks associated with the cost of poor quality (COPQ) and its detrimental impact on a business’s performance must be eliminated as early in a product’s lifecycle as possible.

Relyence supplies reliability engineers, project managers, and quality control professionals with comprehensive software tools to effectively evaluate reliability standards for electronics, mechanical systems, processes, and services. With Relyence software, engineers are able to recognize and address failures and risk with speed and efficiency. As a result, they can take the necessary action to meet and exceed reliability and quality objectives.

Reliability Analysis Software for the Commercial Industry

The proliferation of smart technology, the Internet of Things (IoT), and rising consumer expectations mean that electronic component failure analysis must be carried out with more accuracy and ever-tighter deadlines. To meet the needs of the commercial industry, Relyence software is designed to be the preferred electronic component failure analysis software used by reliability and quality engineers.

With Relyence, you get complete mean time between failures (MTBF) analysis that’s supported by fast, efficient data importing and a powerful calculation engine so that your predictions are timely, accurate, and comprehensive. That way, problems are recognized early, preventative measures can be taken, and costly errors like product recalls and expensive warranty issues can be avoided.

Tools for All of Your Reliability Analysis Needs

All businesses in the commercial industry depend on reliability analysis software tools to ensure their production processes are as efficient, safe, and compliant as possible. Relyence offers products designed to work on their own or as an integrated suite — known as the Relyence Studio — to help you meet these goals and overcome common industry challenges. Our analytic tools include:

- Failure Mode and Effects Analysis (FMEA): Relyence FMEA software allows you to detect modes of failure in your products early in their life cycle. Since your business’ reputation lies in your products’ quality, FMEA is an invaluable tool in your manufacturing practices.

- Failure Reporting, Analysis and Corrective Action Software (FRACAS): With Relyence FRACAS/CAPA, you can track customer complaints, failure reports, safety and compliance crises, audit reports, and the corrective actions taken to address these issues in one easy-to-use program.

- Fault Tree Analysis (FTA): Every manufacturing process has many potential modes of failure. Using Relyence Fault Tree, you can model the probability of these high-risk events using a proven probability engine.

- Reliability Block Diagram Analysis (RBD): You can model complex systems — including ones that incorporate redundancy — using Relyence RBD’s powerful mathematics engine. With the software’s intuitive interface, it’s easy to discover how each component of your manufacturing processes contributes to the success of your entire system.

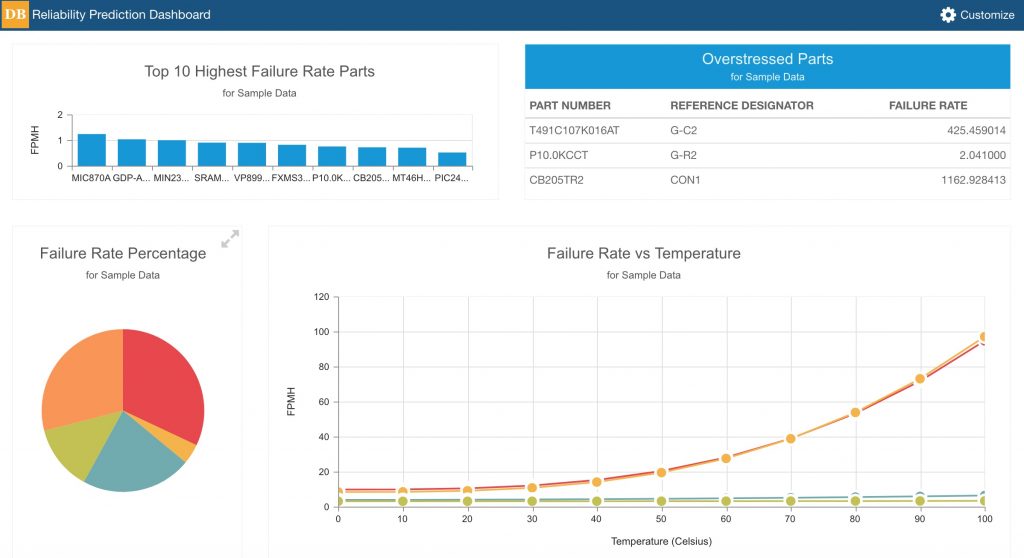

- Reliability Prediction: Analyze your equipment, products, and processes to predict their expected rates of failure using Relyence Reliability Prediction software. This highly precise tool supports many common MTBF analysis standards.

- Weibull Analysis: Uncover lifecycle trends and critical failure data with Relyence Weibull, a major player in determining your product warranty terms and other vital specifications.

- Accelerated Life Testing (ALT) Analysis: Fully evaluate stress data obtained from accelerated life tests with Relyence ALT in order to assess how your product will perform over its lifetime.

Commercial Reliability Standards and Requirements

In order for reliability analysis to be complete, the entire process must meet all applicable industry standards and requirements. For commercial enterprises, the following standards are some of the most important:

- Telcordia: Telcordia SR-332 provides hardware and electronic device reliability prediction procedures that were developed with support and input from major commercial organizations. Designed initially for use in the Telecom industry, this reliability prediction standard is used throughout an array of commercial industries due to its wide applicability.

- MIL-HDBK-217: MIL-HDBK-217F Notice 2 and prior editions are broadly accepted and widely used standards for reliability prediction analysis. Through developed for use in the defense and military sectors, it is the most commonly used reliability prediction standard across all industries. Due to its long history and breadth of electronic devices supported, it remains the standard for MTBF and failure rate prediction analyses. Almost all other prediction standards available today are based on MIL-HDBK-217.

- SN 29500: SN 29500 is a European reliability prediction standard developed by Siemens that is actively maintained and widely accepted by European OEMs and regulatory agencies. It provides information to estimate failure rates for a wide range of electronic components, such as resistors, capacitors, ICs, and relays, in industrial and commercial environments. Its detailed models factor in key influences like temperature, electrical load, environmental conditions, and stress levels. It is especially suited for applications in commercial electronics and industrial manufacturing.

- SAE J1739 & ARP5580: These Society of Automotive Engineers (SAE) FMEA guidelines were developed for the automotive industry in conjunction with DaimlerChrysler Corporation, Ford Motor Company, and General Motors Corporation. The SAE FMEA standard and its RPN (Risk Priority Number) approach to risk assessment is accepted across many commercial industries conducting failure mode and effects analyses.

- AIAG & VDA: The FMEA Handbook, published by the AIAG (Automotive Industry Action Group) and VDA (Verband der Automobilindustrie, or the German Association of the Automotive Industry), defines the Action Priority approach for risk assessment and is accepted throughout commercial industries worldwide.

- ISO and ANSI: ISO 9001 and related quality standards such as ISO/TS 16949, and ISO 14001 are some of the standards most commonly accepted and adhered to in the commercial industry sector. ANSI standards, such as ANSI/VITA 51.1, provide guidelines for reliability and quality measures.

- Six Sigma: Six Sigma quality practices and procedures are often used in commercial organizations to provide effective and proven quality control measures.

Designed to work across all of the above standards, Relyence’s reliability analysis software can consider multiple standards simultaneously so that your analysis models are always accurate and fully compliant with your commercial organization’s specific needs.

Benefits of Using Relyence as Part of Your Reliability Toolset

For trustworthy reliability analysis of electronic components and devices, Relyence Reliability Prediction software comes packed with the following features and benefits:

- Streamlined data entry: With an intuitive user interface, data importing abilities, built-in default values, and well-designed forms, Relyence makes it faster and easier to enter data for analysis, so you can get the insights you need without hassle.

- Custom reports: Generate reports that contain only the data sets you require and export them to a file format of your choosing. The ability to generate custom reports makes it easier to transmit information to stakeholders and convey data in company presentations and meetings.

- An advanced calculation engine: All Relyence software features an advanced mathematics engine capable of performing complex calculations quickly and accurately.

- Built-in component libraries: Relyence Reliability Predication provides built-in access to a component library, which contains data on tens of thousands of parts. Commercial businesses can use this library to make quick reliability prediction analyses for new product designs.

- What-If? analysis: Our What If analysis system allows commercial users to evaluate the trade-offs of different designs, which can help you make better business decisions.

- A customizable dashboard: Completely customize the layout and appearance of your software’s dashboard for more convenient and relevant viewing.

- Easy integration: Commercial businesses may rely on a number of analysis tools. All Relyence software is built to integrate seamlessly with other tools in the suite, so you can use shared data to calculate the most accurate results.

What Commercial Businesses Should Look for in Reliability Analysis Software

Businesses in the commercial industry face incredible pressure from competitors, regulatory bodies, and rising customer expectations. So, deciding on commercial reliability analysis software tools that will help you meet high expectations is crucial. To make this decision with confidence, here are some features you should look for in your reliability analysis tools for manufacturing:

- Core capabilities: Your reliability analysis software needs to perform a number of core tasks, including integrating industry-specific compliance standards and completing calculations accurately. In the Relyence suite, you can find individual software tools that are capable of meeting your company’s core requirements.

- Up-to-date technology: You want your reliability analysis software to feature up-to-date technology to ensure convenience and longevity. With browser accessibility and support for mobile devices, Relyence software is equipped for the present and future of reliability analysis.

- Knowledgeable and responsive support: To ensure you get the most out of your software, look for a product that comes with strong support services. The complete Relyence suite of reliability and analysis tools is supported by our skilled training and technical specialists. With Relyence, you get a partner in reliability.

- Continual product improvement: Your reliability analysis software should continue to innovate and provide improved features over time. At Relyence, we listen closely to customers’ suggestions for improvement.

- A full software suite: Though you may only use one type of reliability analysis now, it’s important to leave room for development. When you choose software from a provider that offers a full software suite, you can expand the tools you use as your business grows.

What Our Customers Say About Us

Subscribe to Our eNewsletter

In addition to providing top-notch products, our dedication to delivering an outstanding customer experience is unparalleled. That’s why we encourage you to reach out to us with questions. And, please subscribe to our eNewsletter to keep up-to-date with what’s happening in quality and reliability in the commercial sector.

Relyence Advisor: Tools & Tips for the Reliability and Quality Professional

Note: You can unsubscribe at any time.

Request a Free, No-Obligation Trial

In addition to providing superior products, we also deliver an outstanding customer experience. That’s why we encourage you to contact us with any questions; sign up for a free, no obligation-trial; or request a free quote today. Remember: Relyence is committed to helping you meet your reliability goals.