Failure Direct Connect

Relyence offers a completely new and innovative approach to integrate your FMEA and FRACAS tools: Relyence Failure Direct ConnectTM. Given our domain expertise, reliability knowledge, software design talents, and highly skilled development team, we recognized that we were perfectly suited to designing and delivering a solution sought after by reliability engineering professionals – integrating FMEA and FRACAS for utmost efficiency.

Failure Direct Connect Overview

Failure Mode and Effects Analyses (FMEAs) are typically done early in the product lifecycle, usually in the design stage. The goal of FMEA is to delineate all potential failure risks and then work to eliminate or mitigate those deemed most critical.

Failure Reporting, Analysis, and Corrective Action Systems (FRACAS), or any Corrective and Preventive Action (CAPA) system, tracks and manages failure reports from later in the product lifecycle – such as during testing, auditing, or when in use by the customer.

The core component of FMEA and FRACAS is failure data, and importantly, the analysis of that data in order to reach reliability and quality goals. Until now, these analyses have been independently managed without offering a way to efficiently connect the failure data they share.

This is where Relyence Failure Direct Connect steps in: offering an innovative and Relyence-only capability to easily and efficiently directly connect your failure data between your FMEA and FRACAS.

The Failure Direct Connect Process

Step 1: To begin, design engineers use FMEA to evaluate potential failures and the effects of those failures in a product design. By assessing the risk of the various identified failures, the design team works to ensure that actions are taken to eliminate, mitigate, or detect those failures in order to bring the design into accordance with risk profile goals.

Step 2: Once the product design is finalized, product development, manufacture, and deployment take place.

Step 3: The product is delivered to the customer. At this point, organizations adopt some type of corrective action management system, such as FRACAS, to track and manage reported issues. Information such as the failure mode, the cause of failure, and other failure related information is recorded in the corrective action system.

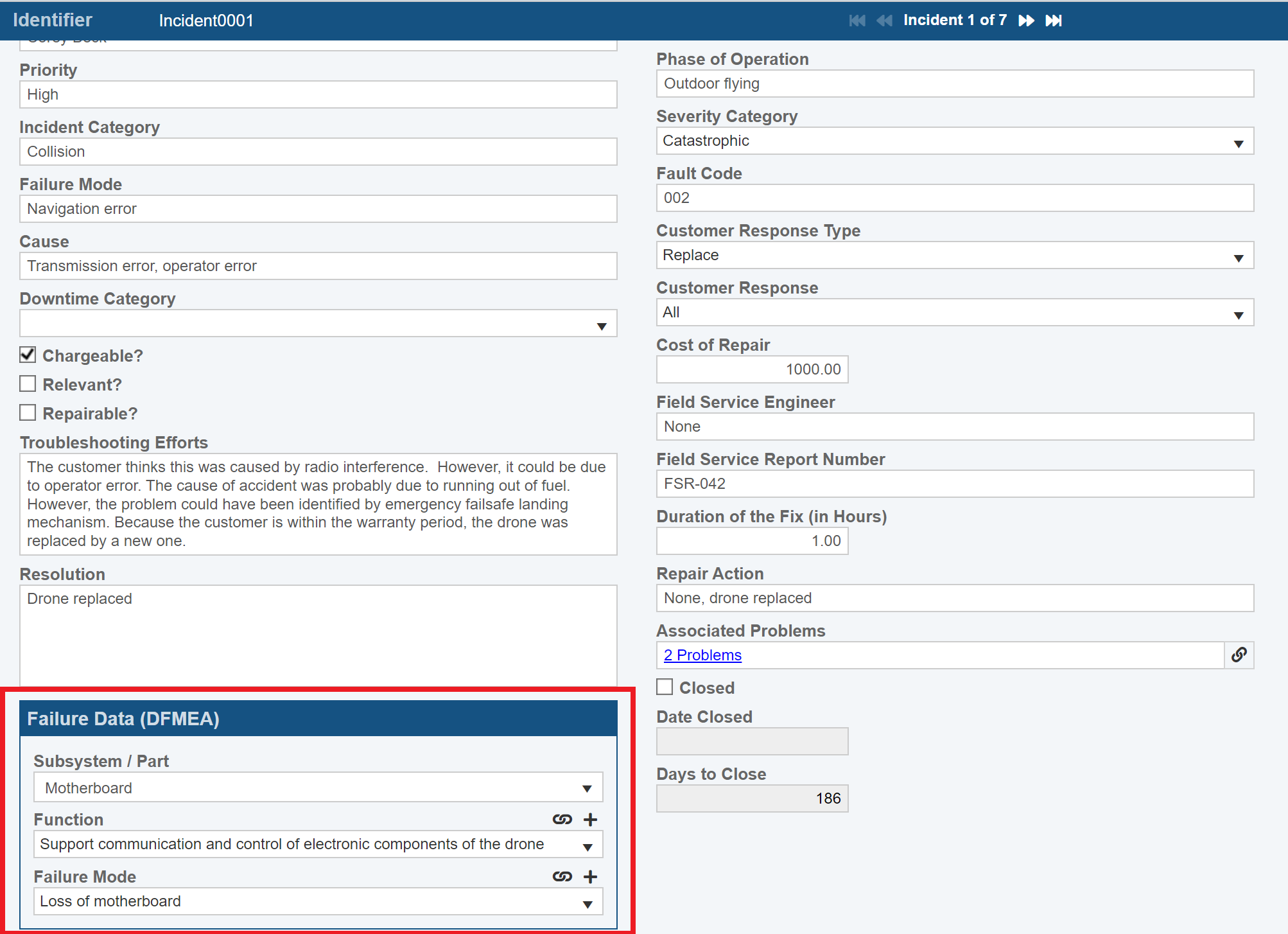

At this stage, it is obvious that the information recorded during both the FMEA process and the FRACAS process directly overlap. With Failure Direct Connect, the FRACAS analyst now has complete insight into the FMEA data. Instead of manually re-entering all the known information, the FRACAS failure data can be directly connected to the existing FMEA data.

Connecting FMEA and FRACAS Failure Data

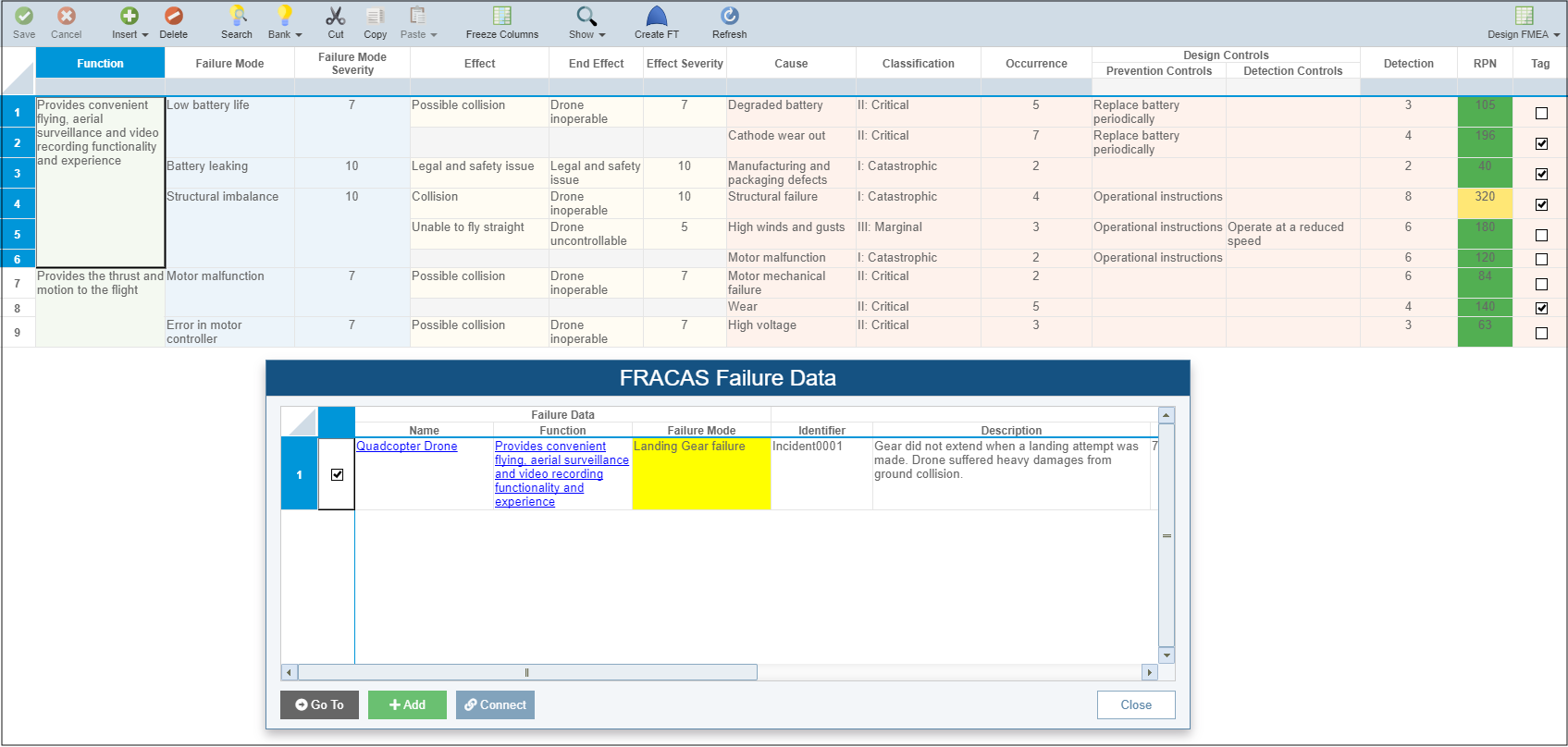

The objective of Failure Direct Connect is to ensure that a failure recorded during the FRACAS process aligns with the failure discovered during your FMEA process. Essentially, you want to know that your FMEA is thorough: your failure analysis covered all potential failure risks. If a new failure is uncovered during failure reporting in FRACAS, it is vital that information is transmitted back to the FMEA team for full analysis.

There are several ways this data connection is kept intact using Failure Direct Connect:

- During FRACAS failure reporting, all FMEA failure information is available to the FRACAS team member. If the failure matches that in FMEA, the FRACAS report is connected to the FMEA information.

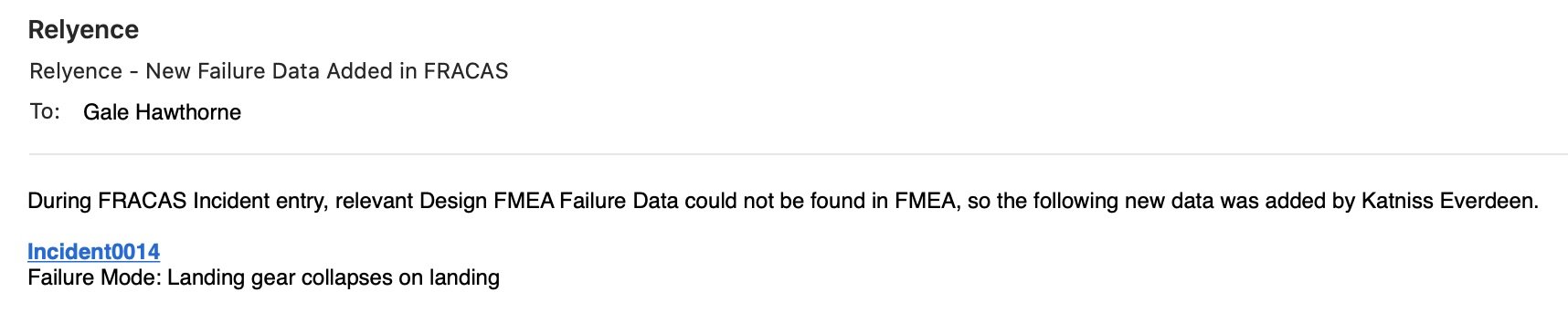

- If a new failure mode has been uncovered during FRACAS reporting, the FRACAS team member can add it and a request is sent to the FMEA team to review and incorporate this new item.

- New failure mode requests from the FRACAS team are reviewed by the FMEA team. Several options are available to the FMEA team to handle the request: the item can be added to the FMEA, connected to an existing FMEA failure mode, or simply disconnected from FMEA.

Advantages of Failure Direct Connect

With Relyence Failure Direct Connect, your FMEA and FRACAS teams can work together to ensure that your failure analysis coverage is complete.

FRACAS team members have complete insight into the FMEA and can directly connect to the FMEA data to leverage already captured failure information.

Newly discovered failure information by the FRACAS team can be sent back to the FMEA team for further review and evaluation if required.

With this innovative new ability to directly connect your FMEA and FRACAS processes, you can see how your overall quality management system becomes fully integrated for maximum effectiveness. Your design engineers and field personnel are now communicating directly. You are not only ensuring all failures are identified, but also that they are properly addressed.

By using Relyence Failure Direct Connect, you can be confident that lessons learned are not lost. Failure Direct Connect provides yet another Relyence-only powerful capability for more expansive and thorough failure control, tracking, and management.