Relyence Failure Mode, Effects, and Criticality Analysis Software

With Relyence Failure Mode Effects & Criticality Analysis (FMECA) software you get an all-in-one package supporting the worldwide-accepted standard for FMECA: MIL-STD-1629A. Whether you prefer to adhere strictly to MIL-STD-1629, or want to customize your analyses, Relyence FMECA enables you to work the way you choose and meet your compliance requirements.

FMECA Standard Calculation for MIL-STD-1629 & More

MIL-STD-1629-based FMECAs can be performed in either a qualitative or quantitative approach. In either case, the core principle remains the same: evaluate and assess all potential system failure modes, the resulting effects and possible causes of those failure modes, and ultimately eliminate, reduce, or mitigate the failures deemed most critical.

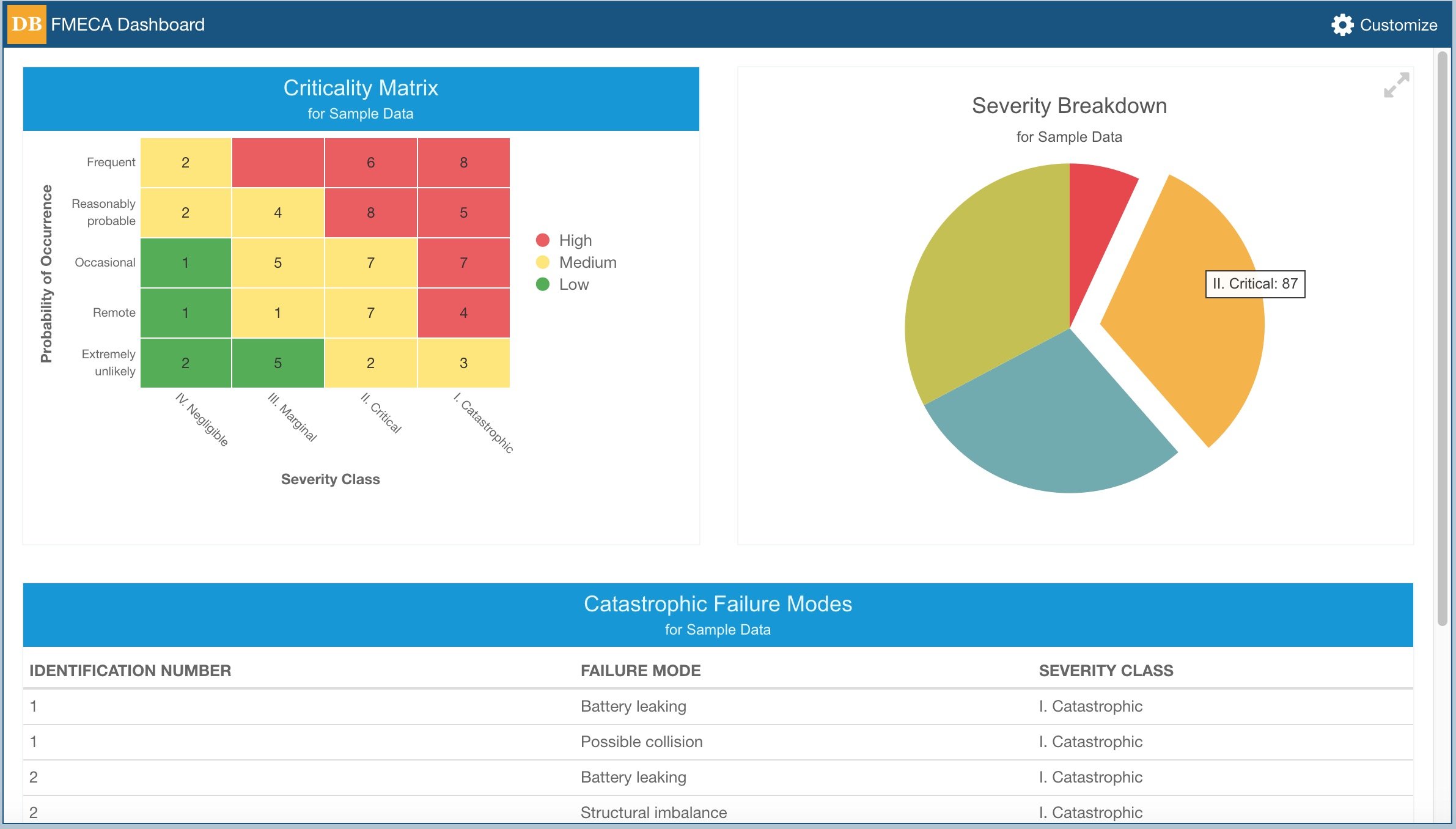

When using a qualitative approach, a criticality matrix is often employed. The criticality matrix is a visual grid of system failure modes categorized by the probability of occurrence and severity level. This data can then be used to organize failure modes by overall risk, providing a way to ensure you address your most critical issues first.

Using a quantitative approach enables you to determine failure mode criticality and item criticality values. This metrics-based analysis allows you to easily rank failure modes in order to begin the important work of eliminating or mitigating the most critical items.

Though not required, MIL-STD-1629 FMECAs can be performed at the piece-part level. In this manner, you determine all the possible failure modes of each individual component in your system, down to the piece-part level. Due to the highly detailed and comprehensive nature of piece-part FMECAs, you can be assured that all potential failure modes are addressed.

Relyence MIL-STD-1629 Criticality Analysis: Tools Built to Meet Your Needs

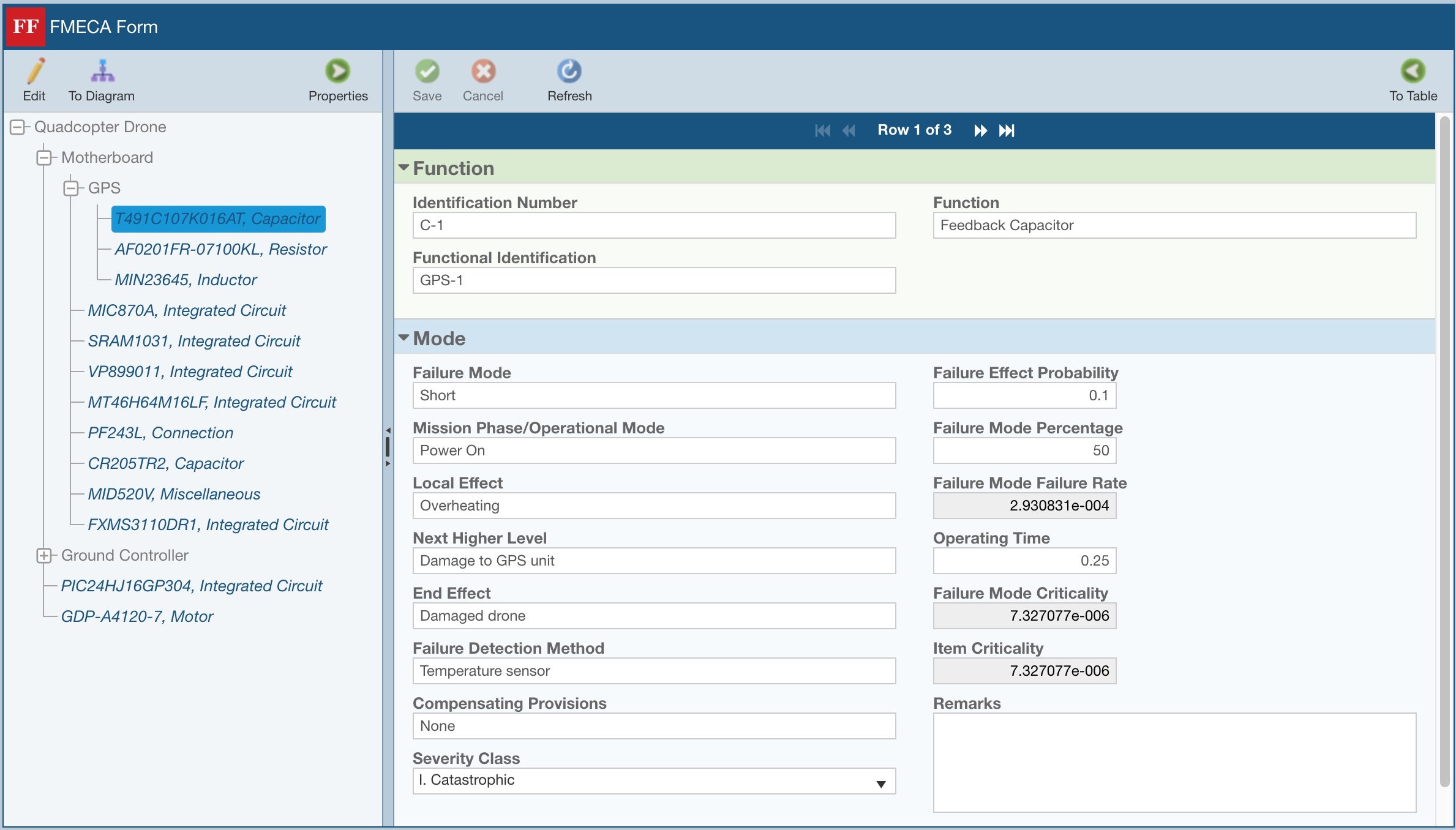

Relyence FMECA offers several built-in, out-of-the-box Worksheets for your MIL-STD-1629 analyses, as well as single item navigable form views.

If you are performing qualitative analyses, you can select the “FMEA” view for your Worksheet. This less complex Worksheet provides the core data fields required for MIL-STD-1629 FMECAs: Function, Failure Mode, Failure Effects (Local, Next, and End), Severity, and other related fields. The FMEA view provides the most basic set of data fields needed to perform a complete FMEA, and meets the requirements for MIL-STD-1629A Task 101.

When performing quantitative analyses, you can choose between the Criticality Analysis Worksheet or FMECA Worksheet. These Worksheets add on the measurement data fields required, such as failure effect probability, failure mode percentage, failure mode criticality, and item criticality. The Criticality Worksheet meets the requirements of MIL-STD-1629A Task 102. The FMECA Worksheet includes all data elements found in MIL-STD-1629A, including part failure rates.

Additionally, you can customize any of these built-in Worksheets, or even create an entirely new one suited to your needs. You can use one of our supplied Worksheets as a starting point and customize it with a few mouse clicks. Also, you can change and modify your Worksheet layout on-the-fly, at any time with no data loss. Different teams or different team members can use their own Worksheet views while all data is automatically shared.

Lastly, no matter what Worksheet view you use, the Relyence FMECA Form views are always available. The Form view allows you to see a single line item in a mobile or small-display friendly way. Navigation buttons enable you to quickly move through the various items in your FMECA Worksheet. In some cases, Relyence FMECA users prefer the Form view over the Worksheet view. Or you can use both – with a simple mouse click you can switch between the Form view and Worksheet view at any time. The choice is yours!

Relyence FMECA Software: Browser-based and Feature-rich

Relyence FMECA combines all the elements needed to support full MIL-STD-1629A FMECAs along with an array of features and functions to make your job easier than ever before.

Relyence FMECA integrates seamlessly with Relyence Reliability Prediction so failure rates needed to perform criticality calculations are automatically retrieved. As with all Relyence products, Relyence FMECA can be part of the Relyence Studio framework to combine any or all reliability analysis tools in one integrated package: FMECA, FRACAS (Failure Reporting, Analysis, and Corrective Action System), Fault Tree, Reliability Prediction, RBD (Reliability Block Diagram), Maintainability Prediction, Weibull Analysis, and ALT (Accelerated Life Testing).

Relyence FMECA incorporates all the unique innovative capabilities developed by the Relyence team:

- Support for the Knowledge BankTM which enables you to capture your lessons learned for reusable data for more automated FMECAs.

- The Relyence-only FMEA Data AutoflowTM capability which offers an automated and customizable approach for handling FMECA data – such as automatically filling in Local, Next & End Effects and Severity up and down your FMECA hierarchy.

- Full Dashboards for a visually impactful, at-a-glance overview, and insight into your most important FMECA metrics.

- Built-in FMD-2016 (Failure Modes Distributions) database for automated retrieval of electromechanical component failure modes.

- Browser-based design for no-installation ease of access across the globe.

- Mobile-friendly design for device independence and wide-reaching accessibility.

These features, along with a host of others, make Relyence FMECA the tool of choice for analysts in a broad range of industries across the world.

Benefits of FMECA: Criticality Analysis Software vs. Excel Templates

Oftentimes, FMECAs are initially performed using an Excel-based approach. While at first glance this approach seems simple, its inherent problems for FMECA tasks quickly become apparent. Some of the features that are central to Relyence FMECA are simply not able to be matched using Excel:

- With color-coded fully-featured Worksheets, the user interface is far more intuitive for FMECA work.

- The availability of a form-based interface for single line item expansion cannot be duplicated in Excel.

- Built-in calculations for criticality metrics, especially those linked to Reliability Prediction failure rates, are difficult, and in some cases, not feasible to implement in Excel.

- The support for a Knowledge BankTM for FMECA data reusability is unmatched in Excel.

- Text-based phrases and searching capabilities in Relyence FMECA keep FMECAs consistent and accurate.

- Built-in support for FMD-2016 enables fast FMECA data entry and builds a solid foundation on which to start your FMECA tasks.

- Available on the cloud for team centered collaboration, device independence, global access, and data sharing.

- Importing and exporting functions supported.

- Customizable dashboards for task management and insight into critical metrics.

- Relyence-only innovations such as FMEA Data AutoflowTM and Failure Direct ConnectTM which cannot be duplicated using simple Excel FMECA templates.

- And more!

Read more on the benefits of FMECA software tools vs. Excel templates.

Start Your FMECA Software Free Trial

Sign up today for your FMECA software free trial – no download required – and see the power of Relyence FMECA in action!

Or feel free to contact us to schedule a free interactive webinar to view Relyence FMECA, ask questions, or get advice on how Relyence FMECA can work for you.

Also, feel free to contact us at any time for questions, concerns, insights, or advice. Our Relyence team is proud of our long track record and experience with failure mode, effects & criticality analyses. We are happy to help!