MAINTENANCE METRICS

Relyence Maintainability Prediction calculates all your most critical metrics for evaluating your repair and maintenance related activities: MTTR (Mean Time to Repair), MCMT (Mean Corrective Maintenance Time), MPMT (Mean Preventive Maintenance Time), and much more. Based on the MIL-HDBK-472 standard, Relyence Maintainability Prediction enables you to optimally design your maintenance procedures.

Metrics

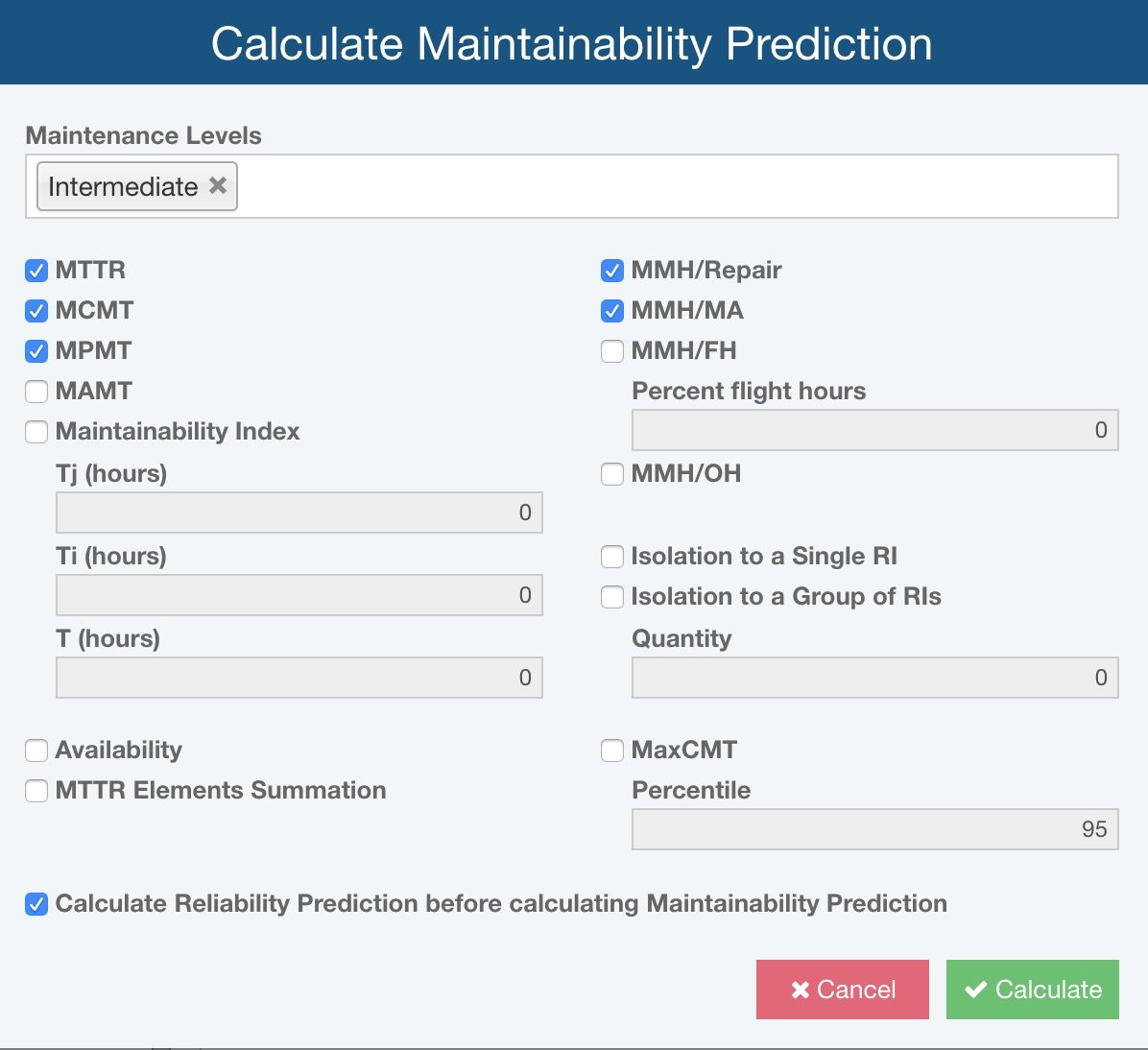

Relyence Maintainability Prediction calculates an array maintenance metrics, any and all of which can be optionally enabled according to your needs. Available Relyence Maintainability Prediction metrics include:

- MTTR: Mean Time to Repair

- MCMT: Mean Corrective Maintenance Time

- MPMT: Mean Preventive Maintenance Time

- MAMT: Mean Active Maintenance Time

- MMH/Repair: Mean Maintenance Hours per Repair

- MMH/MA: Mean Maintenance Hours per Maintenance Action

- MMH/FH: Mean Maintenance Hours per Flight Hour

- MMH/OH: Mean Maintenance Hours per Operating Hour

- Isolation to a Single RI: Percent isolation to a single replaceable item

- Isolation to a Group of RIs: Percent isolation to a group of replaceable items

- MaxCMT: Maximum Corrective Maintenance Time

- Maintainability Index

- Availability

- Individual MTTR Element Values: The summation of the results associated with Preparation, Fault Isolation, Disassembly, Interchange, Reassembly, Alignment, Checkout, and Start Up.

MIL-HDBK-472 Procedures 2, 5A, and 5B

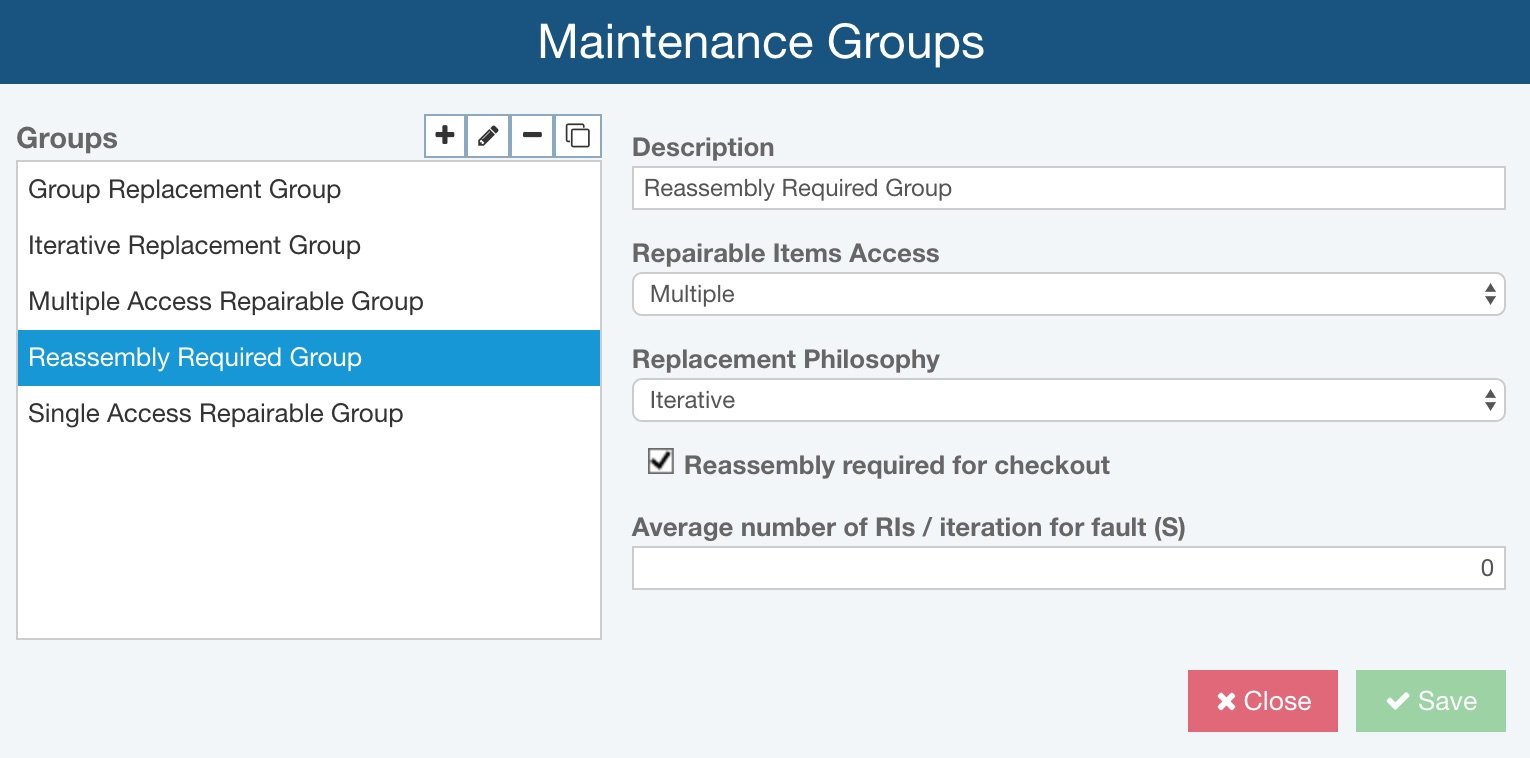

Relyence Maintainability Prediction supports the MIL-HDBK-472 standard including procedures 2, 5A, and 5B. Procedure 2 predictions evaluate the corrective, preventive, and active maintenance parameters of electromechanical systems. Procedures 5A and 5B also analyze these critical maintenance metrics, and additionally incorporates Maintenance Groups to define your replacement and reassembly process.

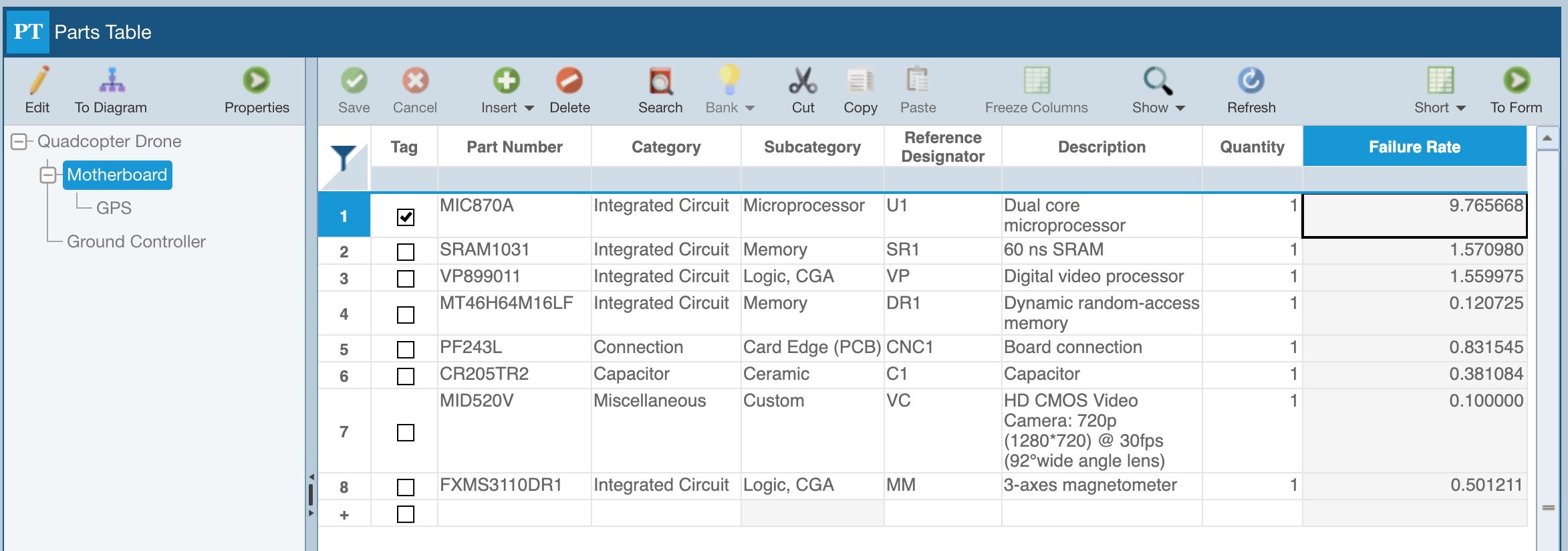

Integration with Relyence Reliability Prediction

Two metrics that are taken into account when performing Maintainability Prediction calculations are repair times and failure rates. You can specify your items’ failure rates directly from within Relyence Maintainability Prediction, or you can use the failure rates calculated in your Relyence Reliability Prediction analysis. If you are using both Relyence Reliability Prediction and Relyence Maintainability Prediction, the failure rates are seamlessly integrated into your Maintainability Prediction analysis. This integration means that your prediction analyses are more efficient, as well as more accurate.

Generating Reports

Relyence Maintainability Prediction has a fully customizable and flexible report generator for viewing your maintenance and repair metrics. You can also generate reports of all your repair input data. Both the analytical result outputs and input data reports can be exported to a variety of formats if needed.

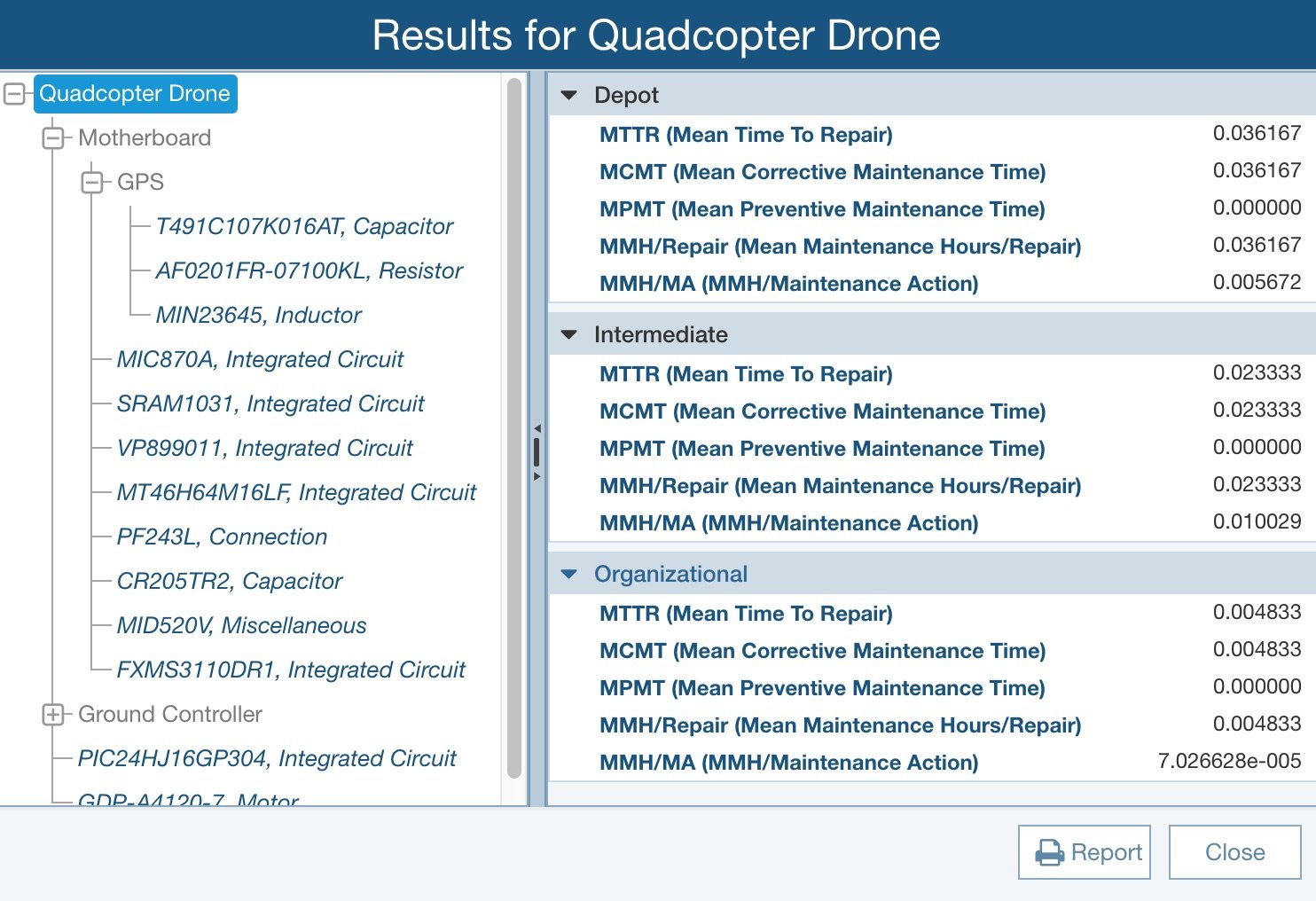

Additionally, Relyence Maintainability Prediction displays all results in a Results dialog once calculations have been completed. You can review all your metrics in the easy-to-navigate viewer and generate a report directly from this view.