IMPRESSIVELY STREAMLINED DATA ENTRY

While reliability prediction analysis is data intensive, Relyence Reliability Prediction was designed to maximize the efficiency of the data entry process. Well-designed part forms, data importing abilities, part number look up, Intelligent Part MappingTM, the Knowledge BankTM for data reusability, default data settings, an easy path from Parts Count to Part Stress analysis, and instant pi factors all enable you to tackle your reliability prediction tasks with ease.

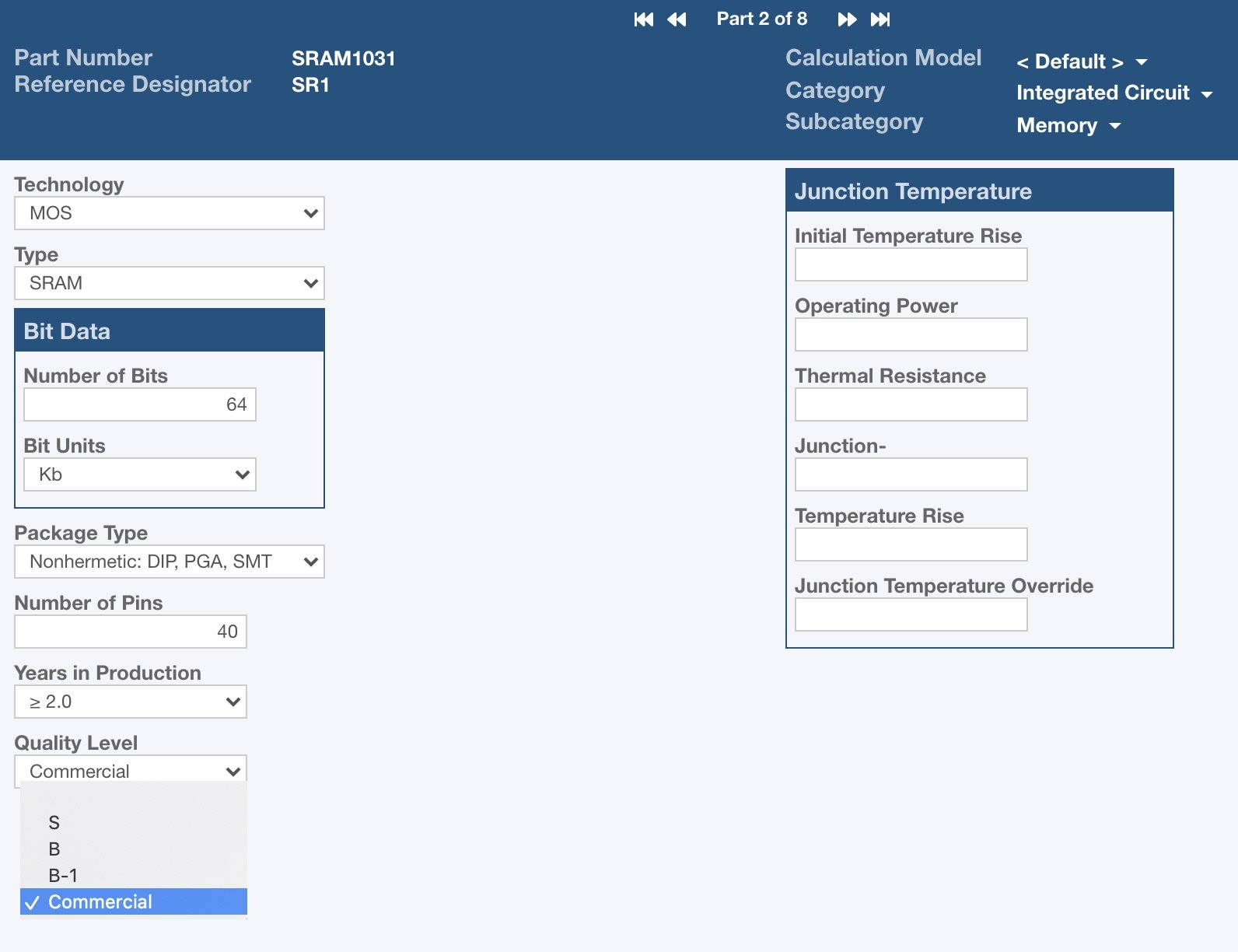

Streamlined Data Entry Forms

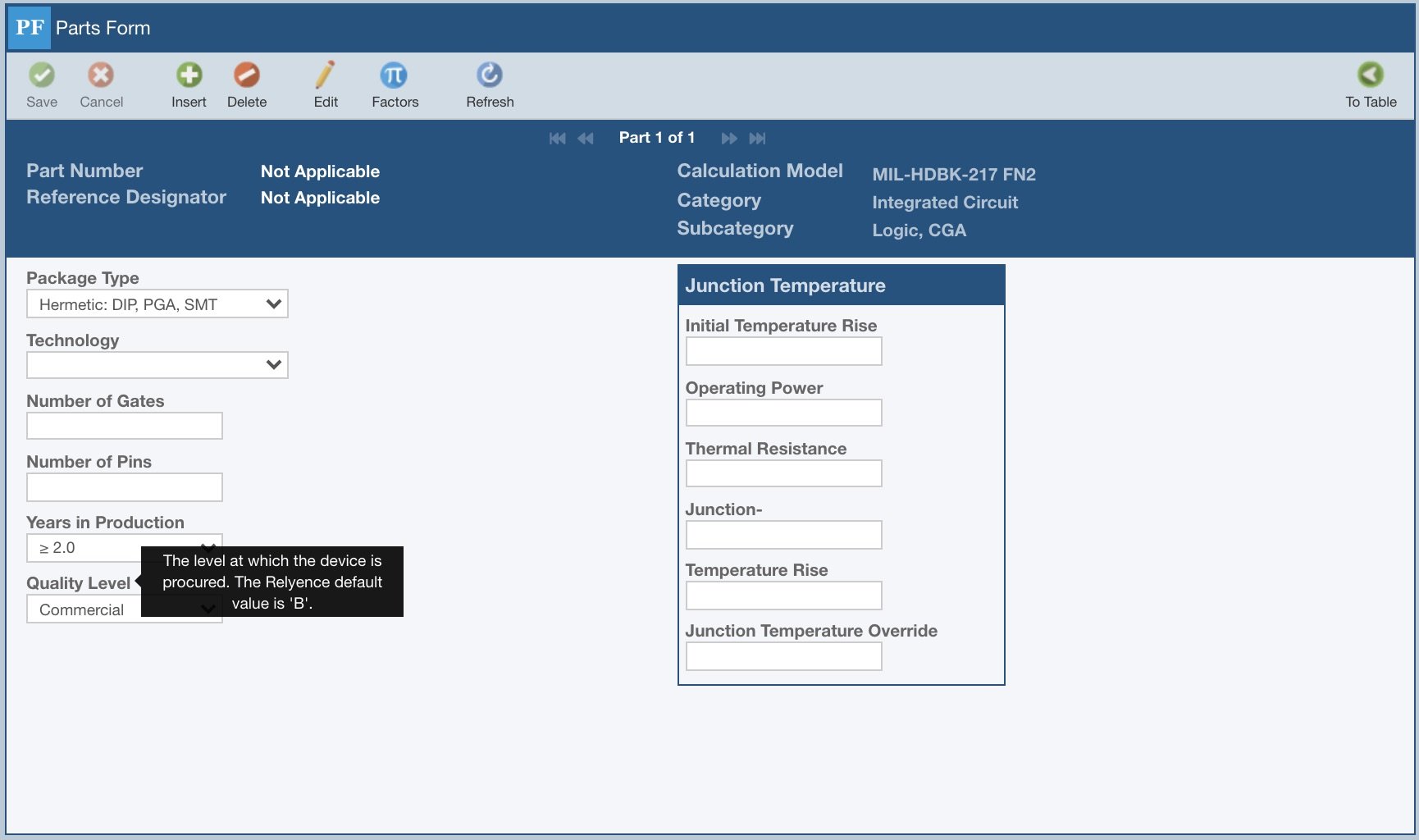

Recognizing that data entry can be a cumbersome task in performing reliability predictions, Relyence Reliability Prediction was designed to overcome this difficulty. As you add components, you are automatically prompted for the appropriate data parameters based on the standards you employ. When applicable, data entry values are presented in drop down choice lists, so you can be sure you are only entering valid parameters. However, if you are unsure of specific data values, Relyence allows you to leave the data blank and will utilize average acceptable values when performing calculations.

Additionally, part number look up and Intelligent Part Mapping features are employed for rapid retrieval of data parameters during the data entry process.

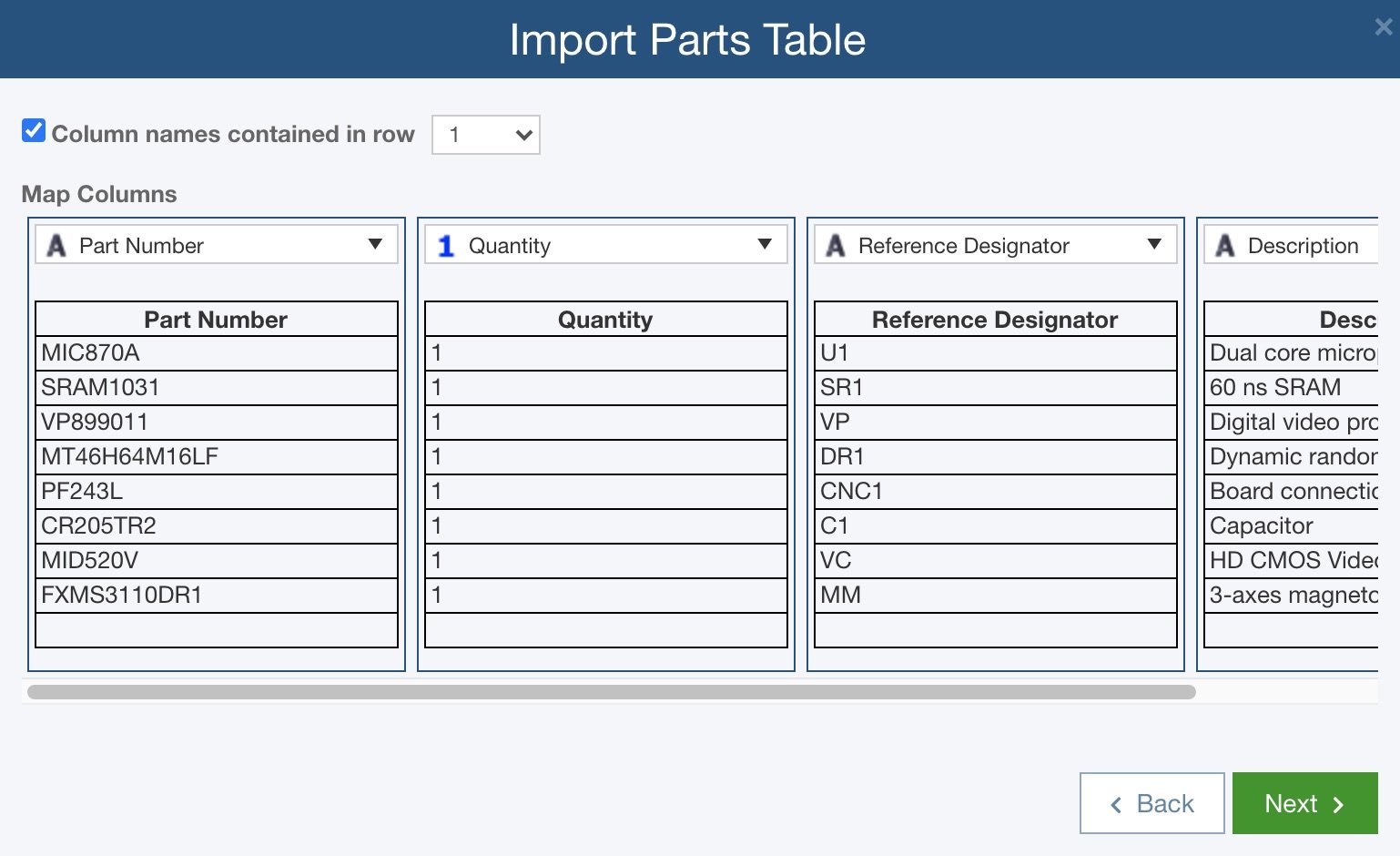

BOM (Bill of Materials) Importing

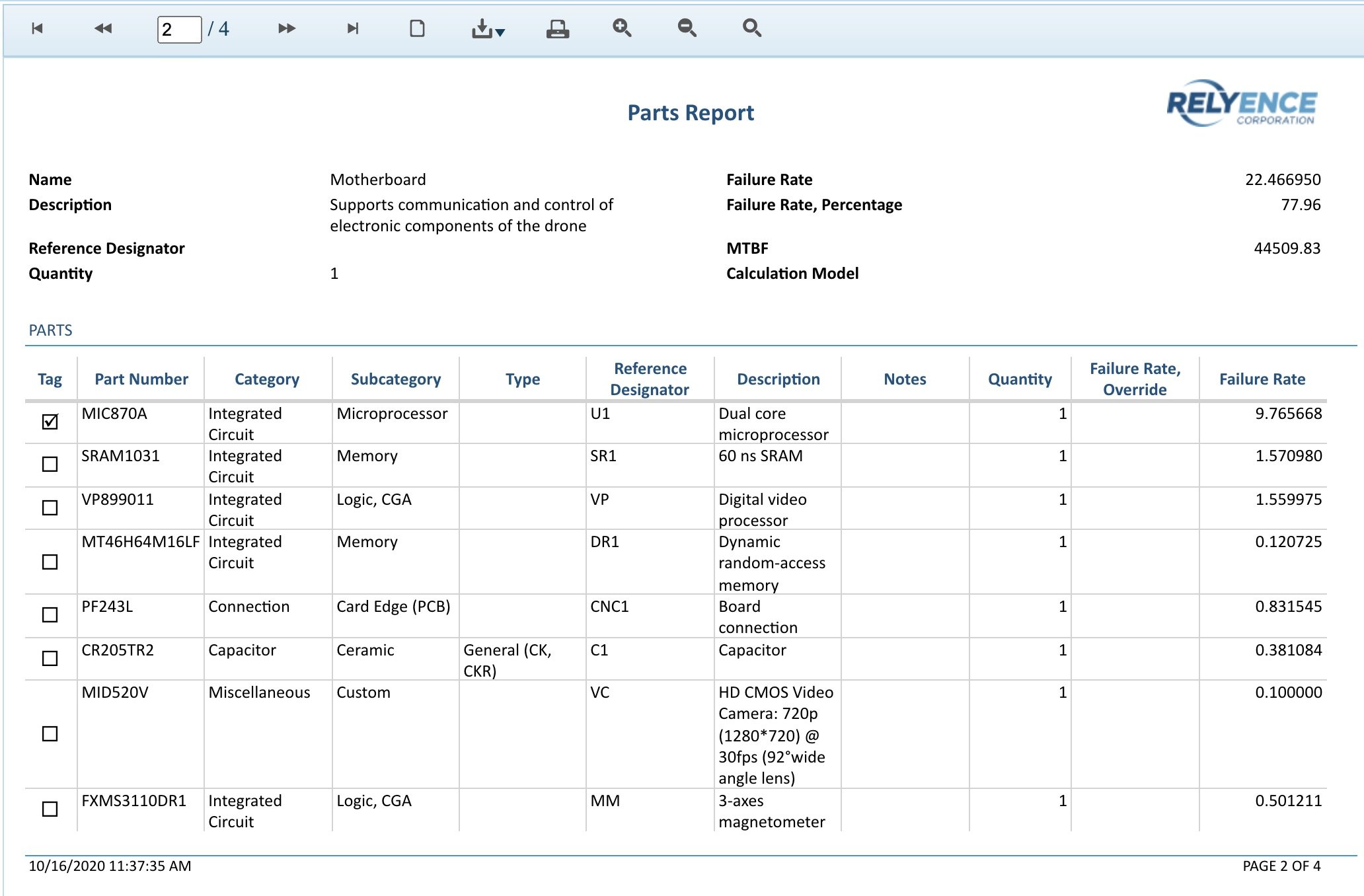

Oftentimes, parts lists are available in a BOM (Bill of Material) format. Using this data enables you to rapidly build up your parts list needed for reliability prediction analysis.

Relyence offers an intuitive, step-by-step Import Wizard to quickly and easily import your BOM into Reliability Prediction. During import, part number look up and Intelligent Part Mapping are engaged, so the resulting import provides a well-defined parts list for analysis. The Import Wizard supports a wide range of import flexibility, allowing you to import not just BOM formats, but any format you have available.

Additionally, you can even copy and paste parts lists from other sources, such as an Excel worksheet for direct entry into Relyence Reliability Prediction.

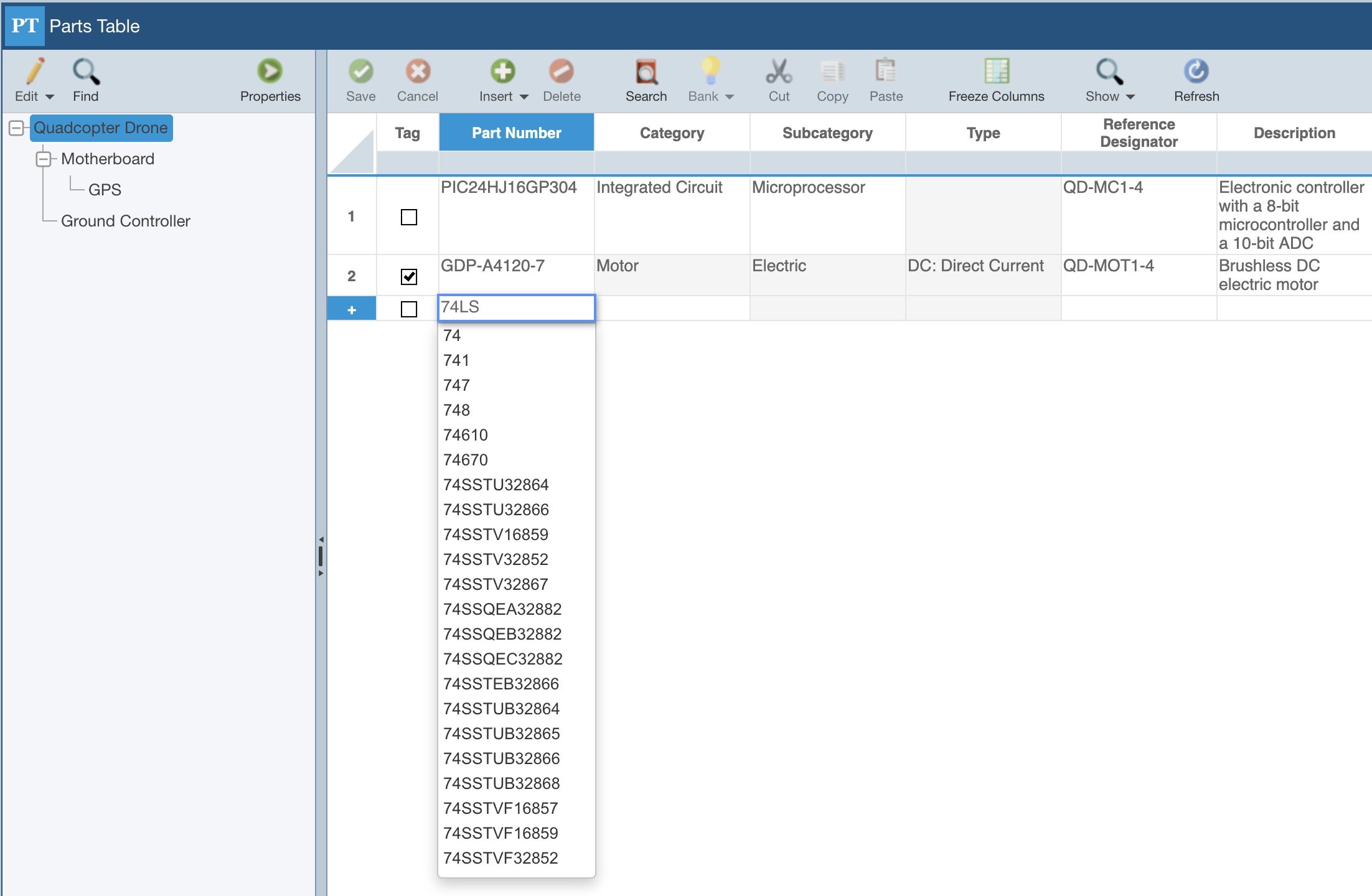

Part Number Look Up

As you enter a Part Number in your Parts Table, the Relyence supplied component parts libraries and your own custom libraries are searched on-the-fly for part number matches. As you continue to type the part number, the list is continually refined to the matching component part numbers, making it easy to find the exact part you are looking for. Once you have found the part number you desire, simply select it, and the associated data parameters are quickly retrieved and entered for you. Or, as you import your BOM into Relyence, the Relyence supplied component libraries and your own libraries are quickly searched for matches, and the corresponding data parameters are automatically retrieved during the import process.

Relyence Reliability Prediction includes a component library containing hundreds of thousands of parts from known manufacturers. The library allows you to quickly and automatically pull in the appropriate component parameter data for quick prediction analyses. You can augment this built-in library by creating and adding components to your own parts library.

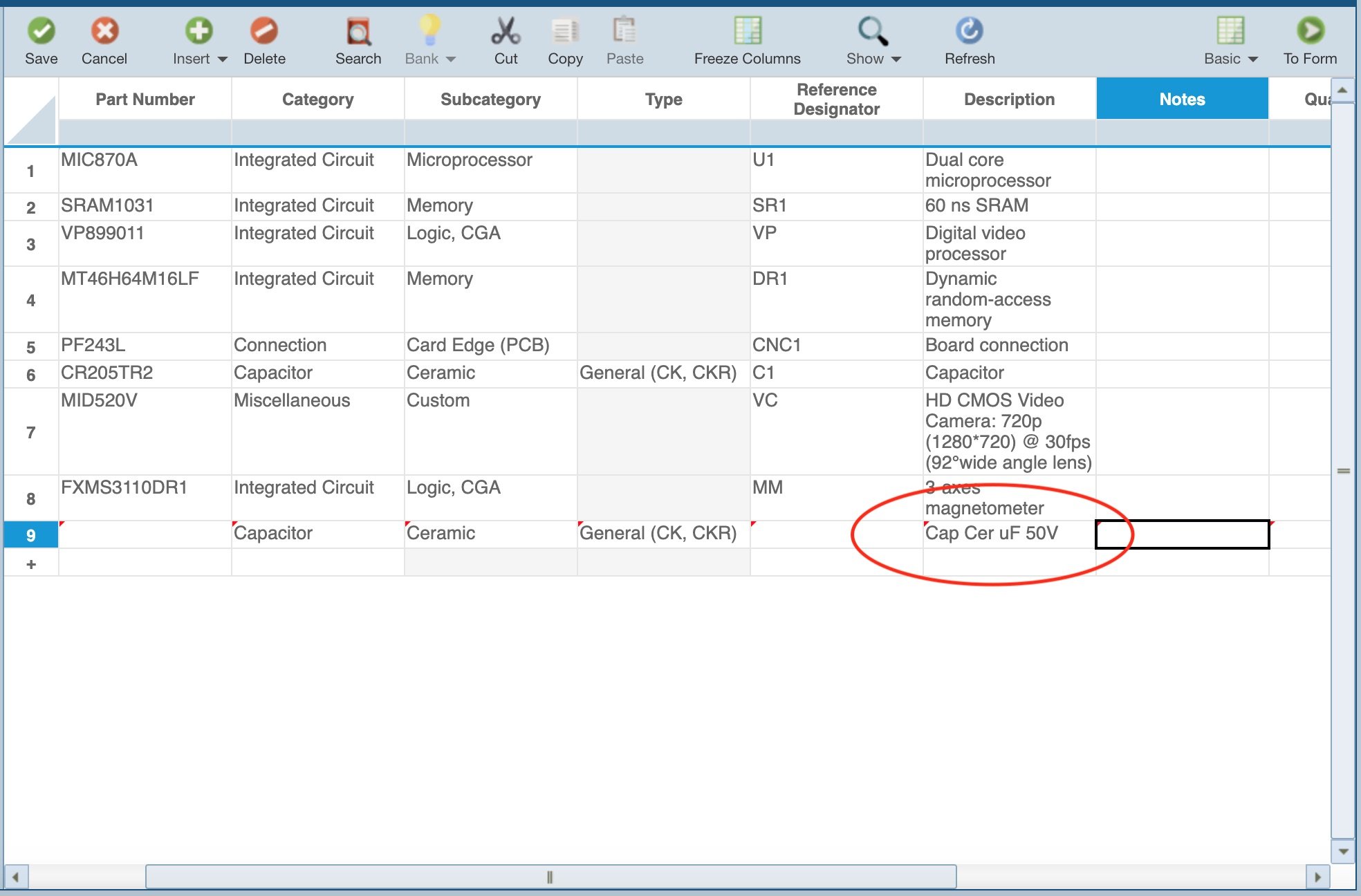

Intelligent Part MappingTM

Relyence Reliability Prediction offers an innovative approach to parts entry: Intelligent Part Mapping. Intelligent Part Mapping reviews your part Description, determines the matching component information, and extracts as much part specific data as possible. Intelligent Part Mapping can be used during data entry and also during importing. Some examples of Descriptions that Intelligent Part Mapping will recognize include:

- CAP CER 10uF 50V

- IC Logic

- RES Thick Film

- CAP 50 nF

- RCR 5W

- Zener

- DIODE

- EEPROM

- FPGA

- CERM 0.2 pF

This unique-to-Relyence capability is continually being updated as more information is gathered and learned. This feature greatly improves the efficiency of part data entry!

Data Reuse with Knowledge BanksTM

The Relyence-only Knowledge Bank feature allows you to expertly reuse your reliability prediction data for the most efficient analyses.

For example, you may have a subassembly used across multiple product lines. Or, you may use subassemblies from prior designs in next generation designs. The Relyence Knowledge Bank replaces the cumbersome and error prone copy and paste method of managing reused subassemblies. You store the component information once in the Knowledge Bank and then reference it where needed. Additionally, modifications made to the reused assembly are automatically kept in sync.

Using the Knowledge Bank in Reliability Prediction for the management and control of reusable components is a simple process:

- Add the subassembly to the Knowledge Bank.

- Reference the stored subassembly in all Analyses where it is used.

- Keep changes made to the subassembly in sync across all Analyses by using the Knowledge Bank Push feature.

Your Knowledge Bank grows over time and becomes a powerful resource for future analyses, enabling you to leverage your data for maximum efficiency.

Default Data Parameters

When entering your parts in Relyence Reliability Prediction, you are not required to enter every data parameter. For any data values not filled in, the Relyence Reliability Prediction calculation engine automatically uses average default values to compute failure rates to provide you with a median assessment of failure rate. As you acquire more information, you can continually update the part data parameters for more accurate failure rate calculations. Relyence makes it easy to view the default value for any data parameter – hover your mouse over the label to bring up the tooltip to display the default value. Also, if you prefer to use your own default values, you can set your own default values for particular parameters. You can choose your own defaults for each and every value, or just for a few if you desire. When calculating, Relyence will first check for your own custom default values, and then check for the Relyence built-in defaults.

Parts Count to Part Stress

Oftentimes, reliability predictions are a process. As your design evolves, you have more design parameters and operating values defined. Relyence Reliability Prediction is built to handle this ongoing evolution: start with as much or as little information as you have. Then continually augment your prediction with known parameters as your design solidifies. One way this can be accomplished is by starting your reliability predictions using the Parts Count methodology. Using Parts Count models, minimal information is required and average operational values are assumed to complete failure rate calculations. When ready, you can then move to the Part Stress methodology which requires more data parameter inputs and results in a more accurate prediction analysis. With Relyence Reliability Prediction, this evolution is easy accomplished: simply select the Parts Count model to start your analysis, then switch to Part Stress and enter your more detailed part data.

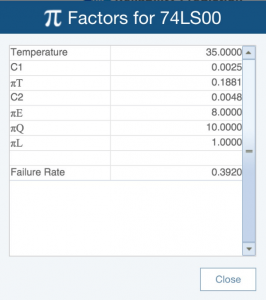

Instant Pi Factors

When evaluating the reliability of your components, sometimes you want to see what factors more heavily influence your failure rate values. Relyence Reliability Prediction’s instant pi factors feature provides that insight. As you are entering your data, you can check the resulting effects on the pi factors, which ultimately reflect in your failure rate and MTBF values. You can also generate output reports with full pi factor details so you can effectively assess those areas that most impact your reliability metrics.