New Year, New Decade, New Release from Relyence! The latest and greatest from Relyence is now available! Relyence 2020 Release 1 introduces a brand-new module and offers a list of impressive new capabilities that further cement the Relyence name as the best-in-class reliability analysis software tool. We take our mission of continual improvement and ongoing advancement extremely seriously. We strive to remain not only best-in-class in our tool suite, but also in our service and support. If you have not yet seen our tools in action, please consider our no-hassle, completely free trial. Or contact us for a personal tour. Your journey to reliability excellence begins with Relyence!

Introducing Relyence ALT

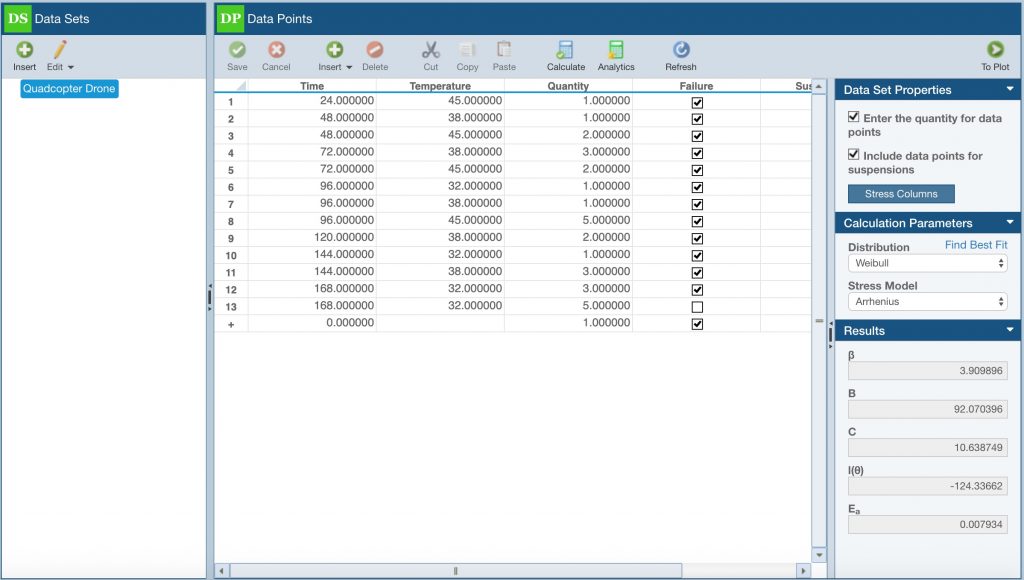

Accelerated Life Testing, or ALT, analysis is a methodology for analyzing various types of life data in order to predict failure trends. ALT analysis is based on high-powered statistical analysis using different distributions for probability assessment.

Just recently, Consumer Reports performed a review on roof shingles. When testing a product whose intended lifespan is 50 years, you can envision why labs such as Consumer Reports need to find a way to test that lifespan in a reasonable time frame – rather than waiting 50 years to see what happens! How do testing labs verify a product’s intended lifespan? Or, how do you, as a product designer, determine with a level of certainty that your product’s lifespan goals will be achieved? That is where accelerated life testing and analysis is vital.

The first step in accelerated life testing is to gather data. For example, to test roof shingles, or other products that are exposed to varying weather conditions over a long period of time, a device such as an accelerated weather tester may be used. Weather testing devices can simulate long-term effects of exposure to weather elements such as light, water, and temperature. Gathering data from devices such as this provides a wealth of life data which can then be used for lifetime analysis.

Once a sample set of life data is gathered, ALT analysis can be performed. ALT analysis uses mathematical and statistical techniques to fit the data to a distribution. Using this information, you can then extrapolate to evaluate trends, assess the probability of a system operating over a time interval, analyze the mean life of a system, predict failure rate, or even determine a warranty period.

Relyence ALT allows you to enhance the capabilities of your reliability software toolset by taking advantage of ALT techniques in your analyses. Relyence ALT supports complete life data analysis, including all the most widely used distributions, such as Exponential, Lognormal, Rayleigh, and Weibull.

Relyence ALT offers a comprehensive tool for accelerated life testing analysis.

Best Fit Distribution Analysis

Relyence ALT includes a Best Fit feature that automatically assesses the best fit distribution for your failure data. The Best Fit feature is a useful tool when you are unsure of which distribution to use. Or, you can also select a distribution and the Best Fit analysis will help you see how close your selected distribution matches the best fit choice.

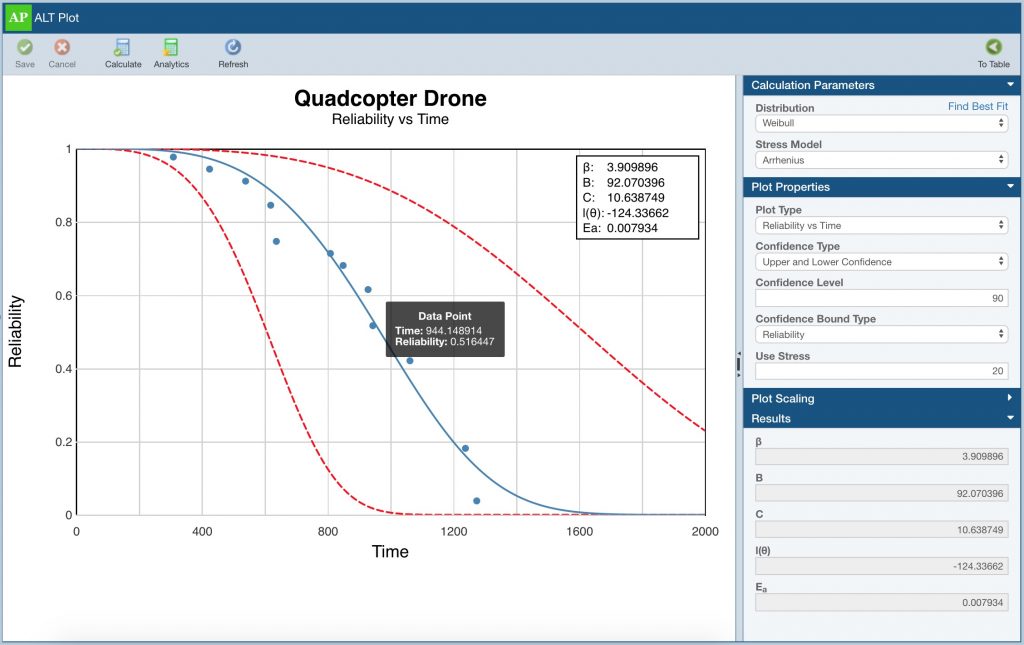

ALT Plots

A central component of ALT analyses are ALT plots, or the resulting graphical representation of your failure data along with the distribution curve. ALT plots are an important element of ALT tools, allowing you to visually see your life data along with the distribution line for full understanding of trends and future performance.

Relyence ALT supports a number of plot types including Acceleration Factor vs Stress, PDF (Probability Density Function) Plot, Probability, Reliability vs Time, Standard Deviation vs Stress, and Unreliability vs Time. You can also add upper and/or lower confidence bounds to your plots, as well customize the legend and plot headings.

Relyence ALT plots are visually impactful and customizable.

As with all Relyence products, Relyence ALT is an integral part of the Relyence platform and is a component of our Relyence Studio integrated tool suite. It exhibits all the unique design elements and powerful capabilities that you expect from the Relyence brand.

Reliability Prediction

Relyence Reliability Prediction now supports two new major feature additions: Allocations and Derating analyses. Both of these capabilities advance your reliability predictions by offering new capabilities to augment your prediction analyses.

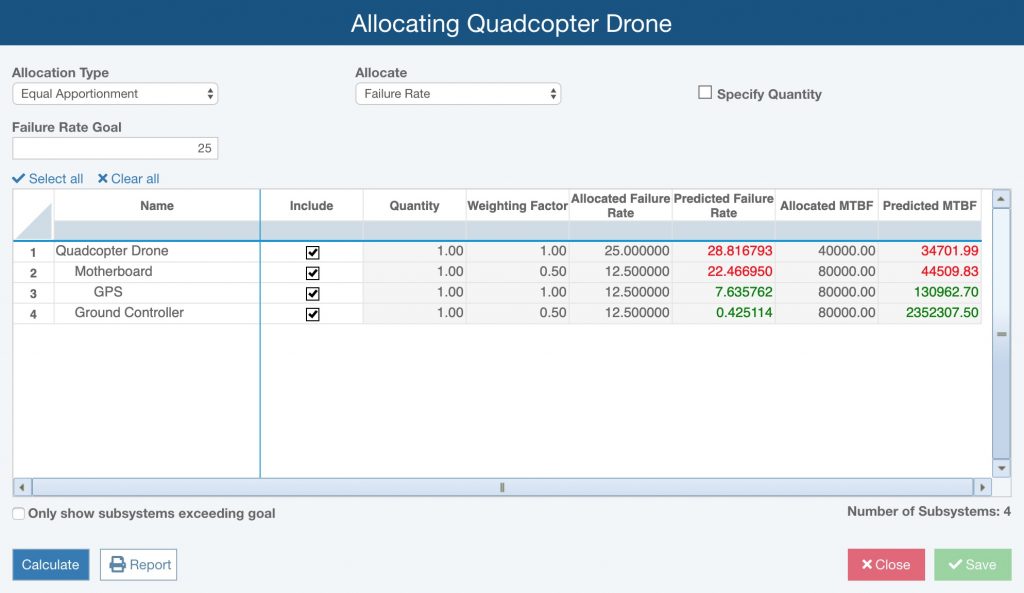

Allocations

Reliability allocation is a process used to optimally distribute reliability goals across a system in order to meet an overall reliability objective. For example, system integrators may have a specific reliability goal either internally driven or contractually mandated. In this situation, it is important to effectively distribute that goal down to subcontractors and suppliers in a reasonable fashion. By establishing reliability goals for each subcontractor, or each subsystem, a system integrator can be assured that the overall objective will be achieved.

There are several proven allocation methods used to perform reliability allocation analysis. Which you select depends on the data you have, as well as your determination as to how best allocate goals.

Allocation methods use various ways distribute the reliability goal based on weighting factors. Weighting factors allow for various measures to influence how much or how little of the overall goal to assign to each subsystem in a system.

Relyence Reliability Prediction supports the following methods for allocation analysis:

- AGREE: The Advisory Group on Reliability of Electronic Equipment (AGREE) developed this allocation method. An Importance Factor is used as the basis for the weight factor for Allocation analysis. The Importance Factor accounts for the complexity of each subsystem (based on number of components in the subsystem), and its overall importance to the system.

- ARINC: The failure rate of each subsystem is entered and used to determine the weighting factor for Allocation analysis. Typically, the predicted failure rates are used, but specified values can be entered. The allocation goal is distributed across subsystems based on their associated portion of the overall predicted failure rate.

- Equal Apportionment: The goal is distributed equally across all subsystems; therefore, no weight factors are required.

- Feasibility of Objectives: The weight factor for allocation is determined based on 4 rating factors: Intricacy, State of the Art, Performance, and Environment.

- Repairable Systems: The availability goal is distributed across all subsystems using MTTR values as the weighting factors.

- Weighted: The goal is distributed equally across all subsystems based on the weight factor entered.

Relyence Reliability Prediction can perform failure rate allocations using a variety of methodologies.

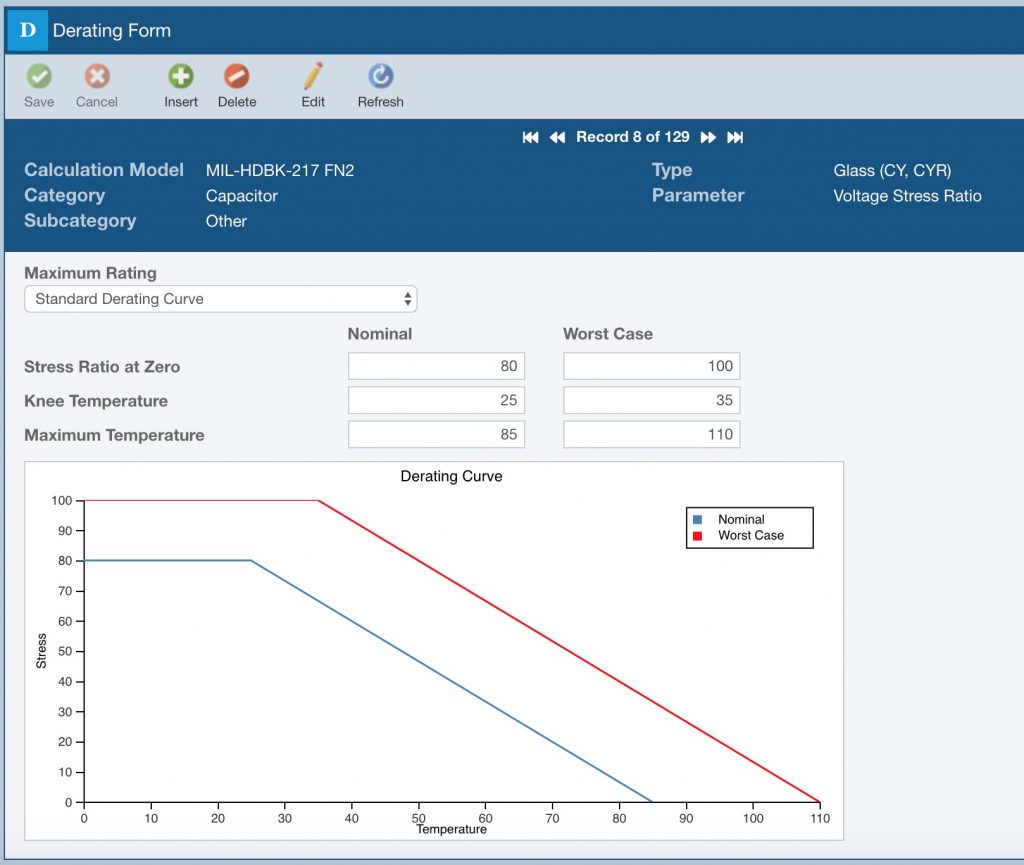

Derating

All electronic devices are subjected to various stresses, such as electrical (for example voltage or current), temperature, and environmental (for example vibration or shock). Component data sheets include information on maximum stress levels that a component should be subjected to in a design. Derating, or operating a component at less than its maximum stress, is employed in order to prolong a component’s life and, ultimately, maintain a high level of overall product reliability.

As part of a reliability prediction analysis, component operating stress compared to maximum stress can be evaluated. In the default case, Relyence Reliability Prediction will flag any components operating over the maximum stress values. However, in most cases, it is preferable that devices operate at some level below the maximum threshold. Determining what the level of stress that is acceptable is based on your own product requirements. You may have your own levels of acceptable stress, or you may want to use a published derating standard that delineates acceptable levels of component stress.

In Relyence Reliability Prediction, you can choose from one of the built-in derating standards, create a completely custom derating profile, or start with a supplied derating standard and modify it to suit your needs. Relyence Reliability Prediction supports the following commonly employed derating standards:

- MIL-STD-1547

- MIL-STD-975M

- TE000-AB-GTP-010

Relyence Reliability Prediction automatically performs derating analysis during failure rate calculations. Any components exceeding their stress limitations are flagged and appear in red on your tables and reports. Using the Relyence Pi Factors feature, you can view the specific overstress condition for any component in your Analysis.

Relyence Reliability Prediction supports derating analysis based on one of the built-in standards or your own custom settings.

FMEA

Relyence’s best-in-class tool for FMEA (Failure Mode and Effects Analysis) now comes equipped with two new impressive features: FMEA Workflow and Knowledge Bank Push Notifications.

FMEA Workflow

FMEA Workflow enables you to efficiently control your FMEA process. This new FMEA Workflow works alongside our powerful FMEA Action Workflow capability. You can use either one, both, or none – the choice is yours. The new FMEA Workflow provides a high-level mechanism for controlling your overall FMEA process from start to finish in a way that manages your FMEAs the way you want.

Though FMEA Workflow usage is not required, it allows you to manage and track your FMEA progress in an all new way. FMEA Workflow is completely customizable and is designed to allow you define your process to meet your specific needs.

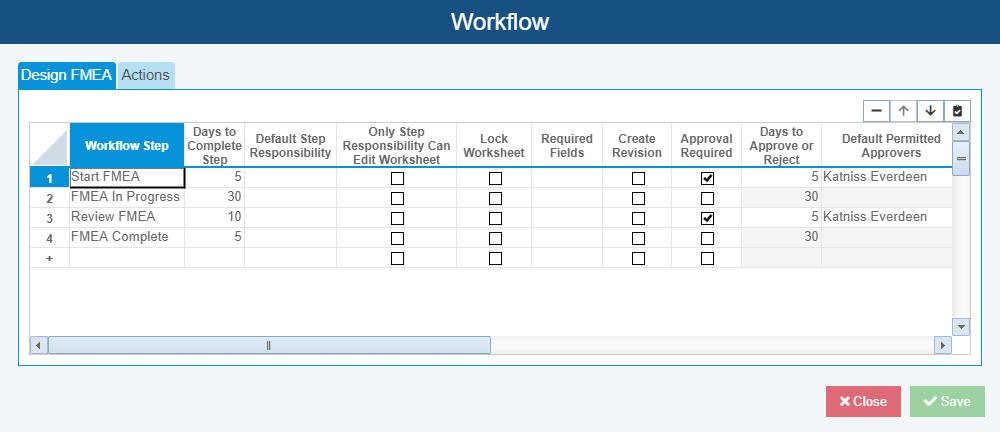

No two FMEA Workflow processes are alike, but an example process could look like this:

- Start FMEA: A FMEA is started for a subsystem. Approval is requested from a team leader to accept FMEA kick-off.

- FMEA In Progress: Upon approval by the team leader, the team leader assigns the FMEA to a team member for completion.

- Review FMEA: Once the FMEA is completed, the responsible team member requests a review for approval.

- FMEA Complete: Once approved, the FMEA is designated completed.

You can choose to include Approvals on any step of your FMEA Workflow, or on none, however you prefer. If used, Workflow cannot not progress until Approval is obtained.

FMEA Workflow is completely customizable to enable you to control your FMEA process as you choose.

Additionally, you can set up Notifications as you desire for your Workflow steps. Notifications are completely customizable and are used to apprise team members of important situations. For example, you may want to set up a Notification to occur when a new FMEA is started, when a FMEA is overdue, or when a FMEA has been approved.

Knowledge Bank Push Notifications

The FMEA Knowledge Bank is a must-have feature for organizations who are committed to making sure their FMEA process is well-managed and efficient. Many of our customers rely on the FMEA Knowledge Bank for consistency, to track lessons learned, and to automate reusability.

Knowledge Bank Pushes are the mechanism for updating FMEAs with any updates made to your FMEA Knowledge Bank. When a Knowledge Bank is modified with new data, any and all FMEAs tied to the data in the Knowledge Bank are automatically updated to reflect the newest information through the Push capability. Now, you can choose to notify team members whenever a Knowledge Bank Push has occurred. Simply define the list of team members to notify and emails will automatically be sent upon a Push update.

Additional Relyence 2020 Release 1 New Features

A long list of additional capabilities is available in our new release. Some of the new features include:

Filtering FRACAS Calculations

You can now select which Incidents to include in your FRACAS metric calculations. For example, you can select the type of Incidents to include (for example Closed or Tagged), or apply date ranges if desired.

Default Values

You can now specify default values to be automatically entered during data entry. For example, you can set default values for fields when a new Subsystem is created, or a new Part or Incident is created.

Grouped Columns

You can now Group related fields on Tables. For example, you can specify a Group Title to appear across multiple columns in your FMEA Worksheets, your Parts Table, or Incident Tables. Grouped columns help to organize your Tables for viewing and reporting purposes.

Links to items in Audit Reports

Audit reports now include a hyperlink to the item so you can go directly to the item in question with a single click.

New permissions for Users, Groups, and Active Users

User and Group permission settings have been broken down further for enhanced control of Users and Groups.

Free Trial of Relyence 2020

If you are not already a Relyence customer, you can sign up for completely free trial. No hassle, no strings, just register here and put us to the test!

Relyence 2020 Release 1 continues our tradition of always improving. Creating is our passion and we love nothing more than building and delivering tools that exceed your expectations. We strive to keep you front and center, and hope you continue to share with us your suggestions for new ideas and improvements.

Call today to speak to us about your requirements or schedule a personal demo at your convenience.