RCM ANALYSIS

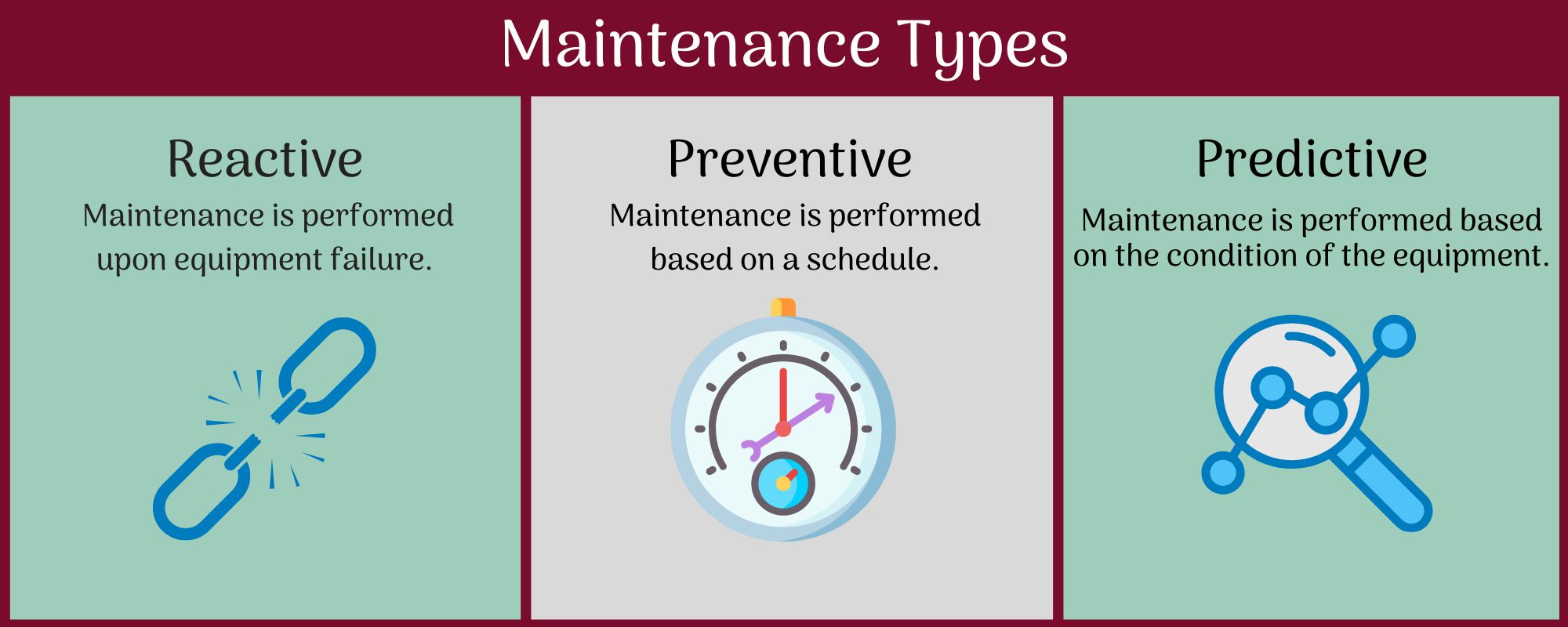

Relyence RCM offers an effective platform for your Reliability Centered Maintenance analyses, enabling you to create the most cost-effective and efficient maintenance plans. Prioritizing your maintenance activities with RCM ensures you achieve the optimal balance of reactive, preventive, and predictive maintenance strategies.

Relyence RCM: Achieving Reliability Centered Maintenance Objectives

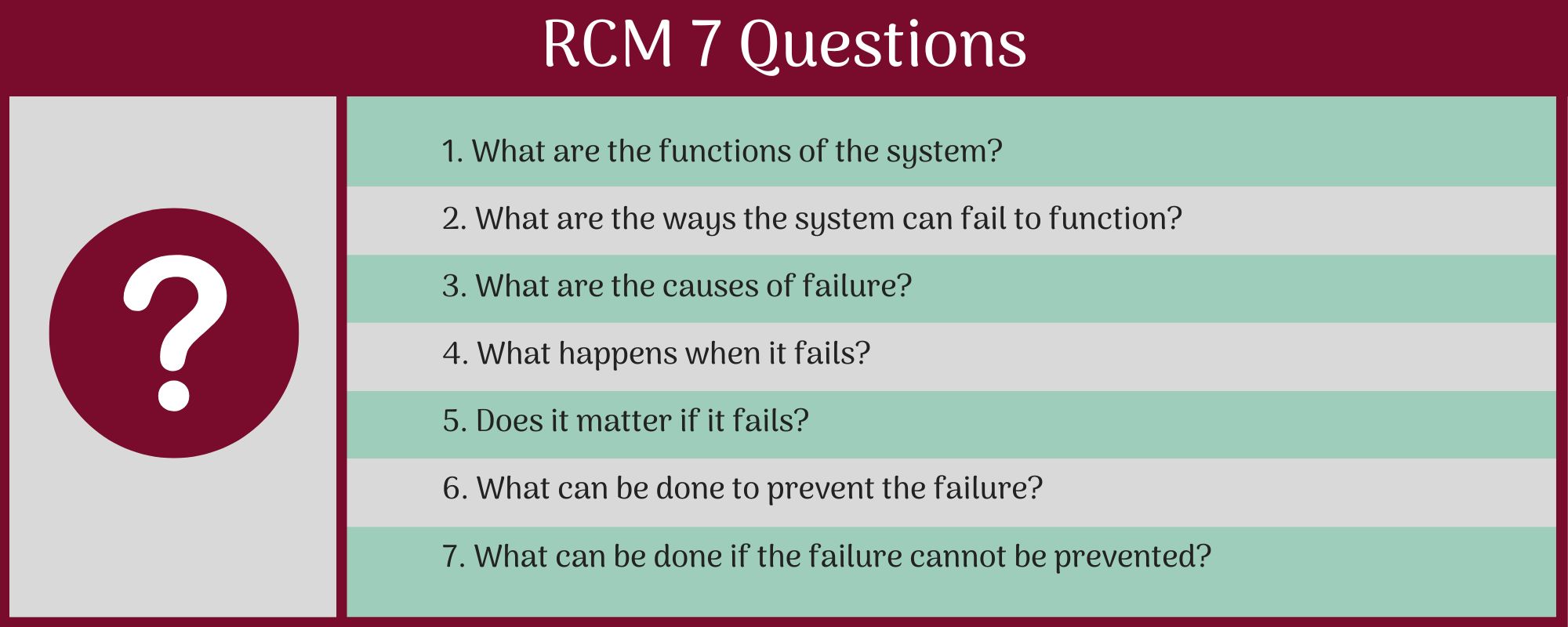

The core principle of Reliability Centered Maintenance is to enable you to most effectively develop your maintenance plans. The concept is to create maintenance strategies that balance handling the most critical failures with efficient use of resources, while also eliminating unnecessary maintenance tasks.

In many cases, repair activities are reactive: a repair is completed when a failure has occurred. This often leads to downtime, which can be costly to your organization. In some cases, reactive repairs can be avoided by incorporating preventive maintenance tasks that are performed in order to prevent or mitigate failures. Preventive maintenance tasks are performed on some type of scheduled basis. An example of a preventive maintenance task is lubricating bearings monthly or performing an oil change on a vehicle every 10,000 miles.

Reliability Centered Maintenance evaluates reactive and preventive maintenance tasks, while also considering predictive maintenance activities to structure a plan to more effectively keep a system operating successfully. Predictive maintenance involves monitoring your system to assess its condition and performing maintenance when it is advisable based on key performance indicators. An example of predictive maintenance is a sensor which monitors air pressure. When the pressure reading remains too low or too high for a specified period of time, a warning is sent to perform repairs as needed.

A unique aspect of Reliability Centered Maintenance is to evaluate in detail the specifics of your system. This begins with analyzing potential failures to see if RCM analysis should be performed on a given asset. For example, it may not make sense to perform a full-scale analysis if a given failure is not critical to the system, does not pose a safety hazard, and is easily repaired. For example, perhaps a bolt failing is a low probability failure, does not cause harm, and is easily detected and fixed by the operator. In this case, no further maintenance planning is necessary, the reactive approach is acceptable. For cases where actions such as lubricating are important to prevent failure, scheduled maintenance is the most effective. And, for the most crucial elements, predictive maintenance is the most beneficial in order to monitor an asset’s condition to avoid a high-risk failure.

Therefore, Reliability Centered Maintenance analysis results in the most advantageous maintenance plans for your organization. And Relyence RCM offers the best platform for robust and complete analyses.

RCM Analysis Start to Finish

Relyence RCM is your complete Reliability Centered Maintenance software package. Built and designed for ease-of-use and efficiency, Relyence RCM offers a compliant and flexible framework for performing comprehensive and effective RCM analyses.

Relyence RCM supports the most widely accepted standards for RCM analysis including SAE JA1011, SAE JA1012, MIL-HDBK-2173, and NAVAIR 00-25-403. It also supports RCM analyses based on any FMEA type: Design, Process, FMECA, FMEA-MSR, and piece-part FMEAs. The built-in templates enable you to get up and running in minimal time. The supplied formats can be customized as needed or you can create your own templates based on your own unique requirements.

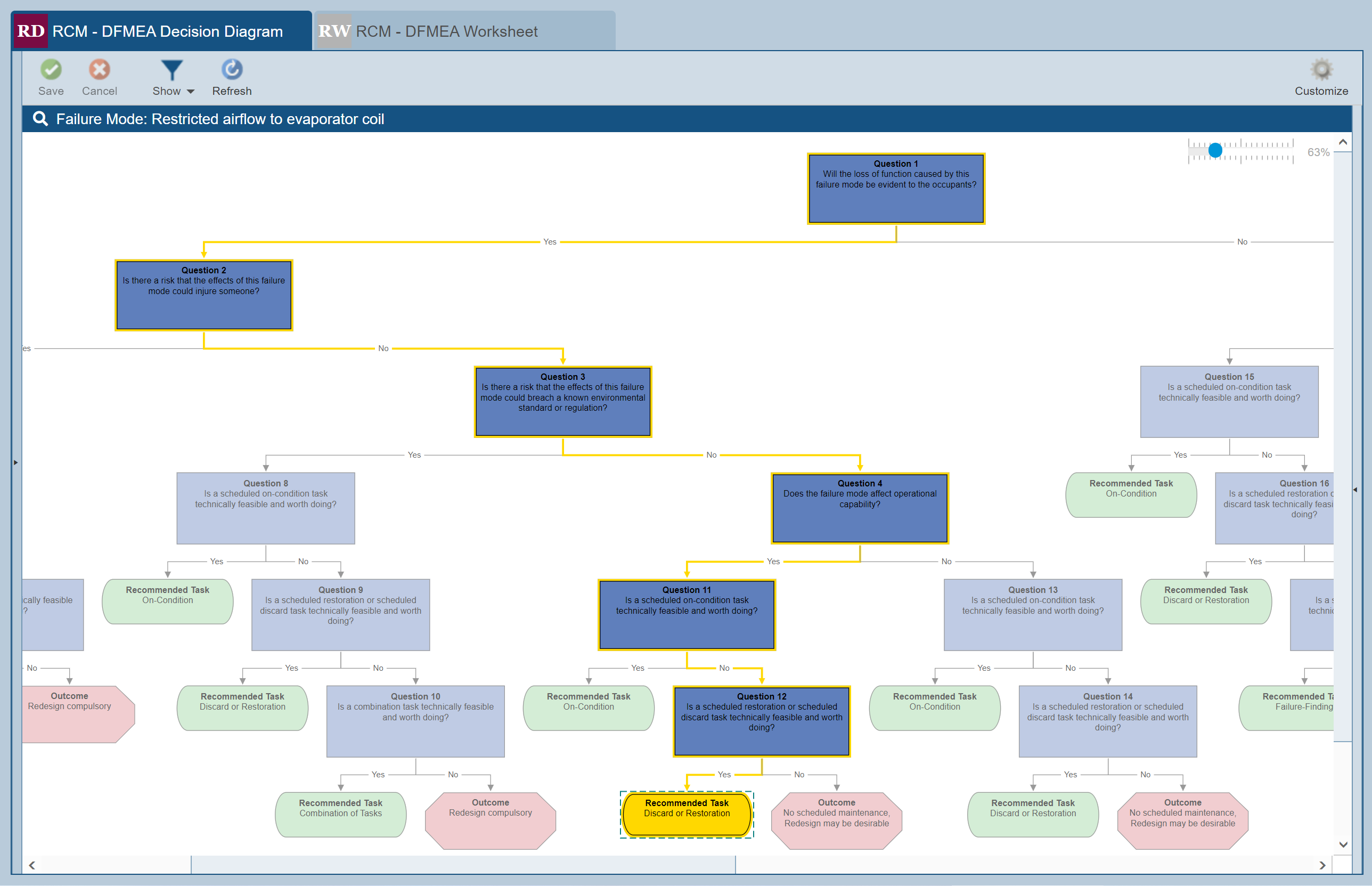

Relyence RCM incorporates the intuitive Guided Decision Diagrammer with adaptable RCM Worksheets. The software is rounded out with the features and functions of the powerful, best-in-class Relyence Studio reliability and quality platform.

Decision Diagrams

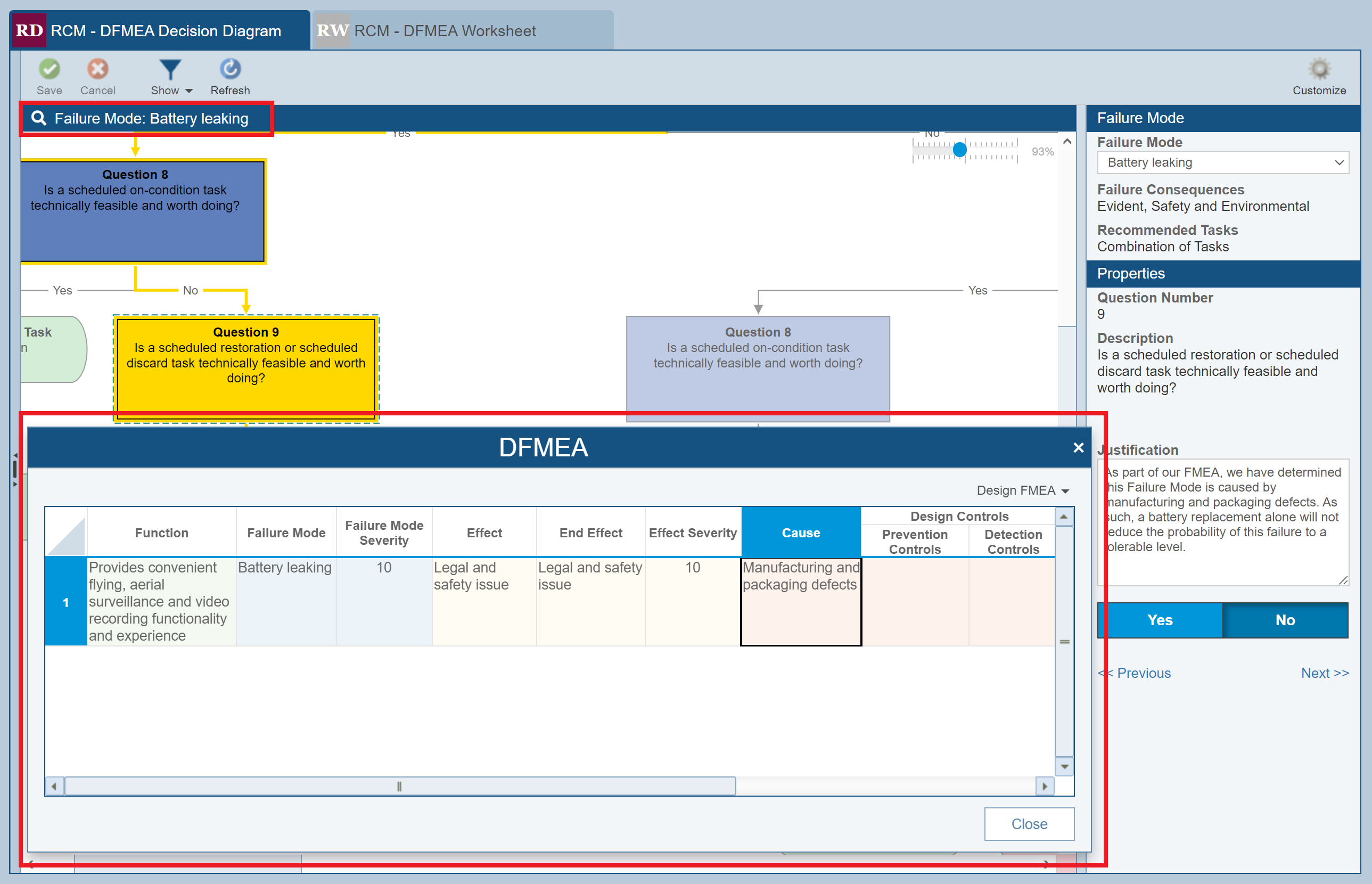

Relyence RCM incorporates our Guided Decision Diagrammer which allows you to progress through the series of questions in order to develop the most efficient and effective maintenance plan. Our built-in decision trees can be used as-is or can be modified if needed. Or you can create your own set of questions and build a custom Decision Diagram.

The Relyence RCM Decision Diagram offers an easily navigable tree, guiding you along the process in order to reach a conclusion. The Decision Diagram also has handy features to allow you to zoom in and out for optimal viewing, color coding for quick visual evaluation, and filtered viewing to allow you to focus on the most important branches of your tree.

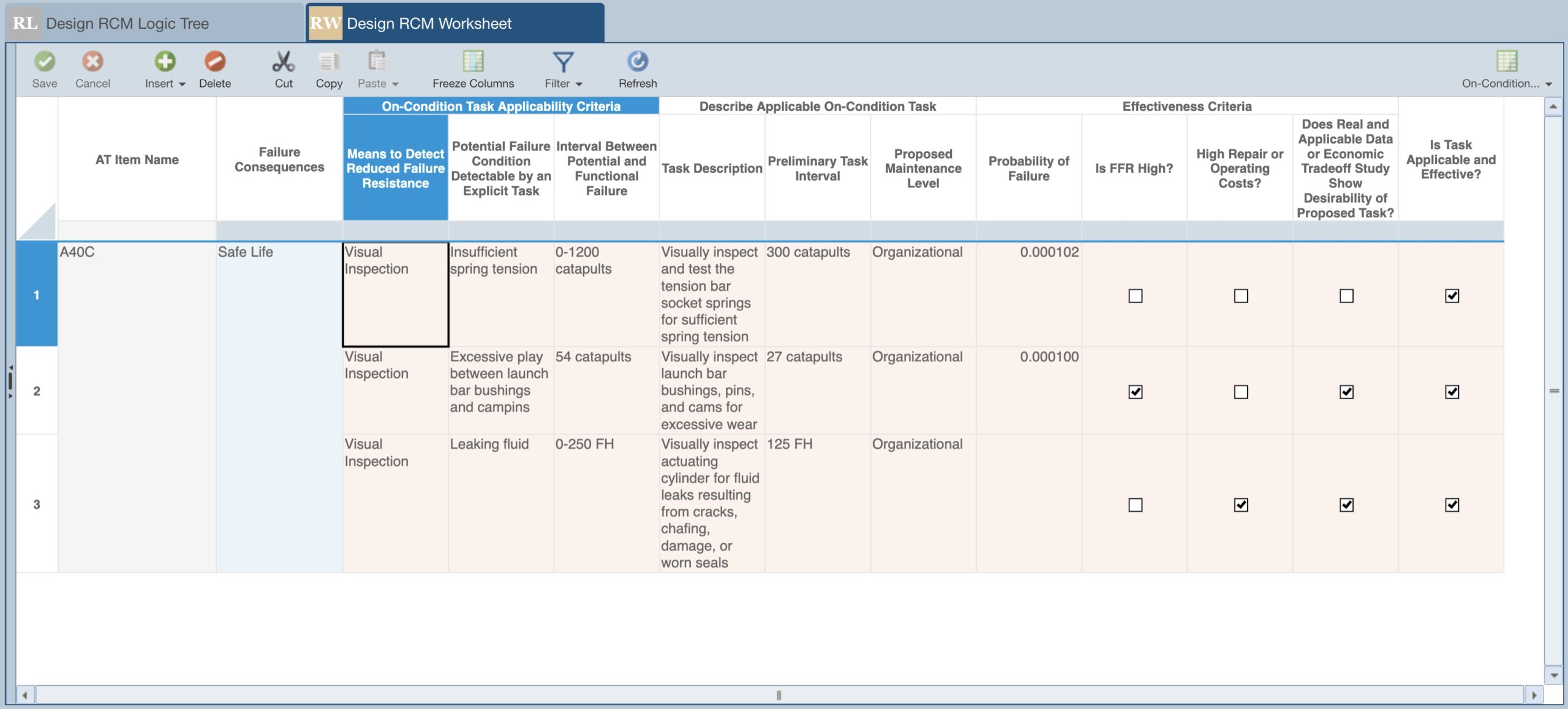

RCM Worksheets

Relyence RCM Worksheets are the core of your Reliability Centered Maintenance analysis. There are several built-in Worksheets that enable you to get up and running in minimal time. They can be modified if needed, or you can create an entirely custom Worksheet if required.

Relyence RCM Worksheets support failure information from any type of FMEA you perform – Design, Process, FMECA, FMEA-MSR, and piece-part FMEAs.

Intuitive and Feature-Rich

Relyence RCM includes an array of additional capabilities to create another trademark best-in-class software solution from Relyence:

- FMEA Worksheet Insight: You can view the relevant FMEA data as needed when progressing through your RCM analysis.

- Adding Questions: You can add Decision Diagram questions directly through the RCM Worksheet interface.

- Autopopulated Data: Task Types and Failure Consequences are automatically populated with information for quick and consistent Worksheets.

- Report Generation: Reports are complete and can be customized as needed.

- Studio Platform: Built on the Relyence Studio platform, Relyence RCM encompasses all the power and flexibility the framework is known for.

- Integrated or Stand-alone: Designed to cohesively work together, Relyence FMEA and Relyence RCM offer a power-packed duo. Or Relyence RCM can operate in a stand-alone fashion.