We’re starting off the new year in Relyence-style with our latest release that includes an amazing array of powerful and unique capabilities! We are excited to introduce a number of brand-new features alongside impressive improvements and enhancements to existing functions. As always, Relyence 2022 Release 1 showcases our commitment to continually improving and maintaining our position as the best-in-class reliability and quality software.

NSWC-11 Mechanical Calculation Model in Reliability Prediction

Relyence Reliability Prediction supports the most widely accepted global standards for MTBF analysis, including MIL-HDBK-217, Telcordia, 217Plus, and ANSI/VITA 51.1. Relyence 2022 Release 1 now offers the ability to perform your reliability predictions using the NSWC-11 Mechanical Reliability Prediction standard.

Developed by the Naval Surface Warfare Center (NSWC), with the latest version being published in 2011, the NSWC-11 Handbook of Reliability Prediction Procedures for Mechanical Equipment details the reliability prediction procedures and models for a variety of mechanical equipment. The types of supported mechanical components include electric motors, gears, bearings, pumps, gaskets, and many more.

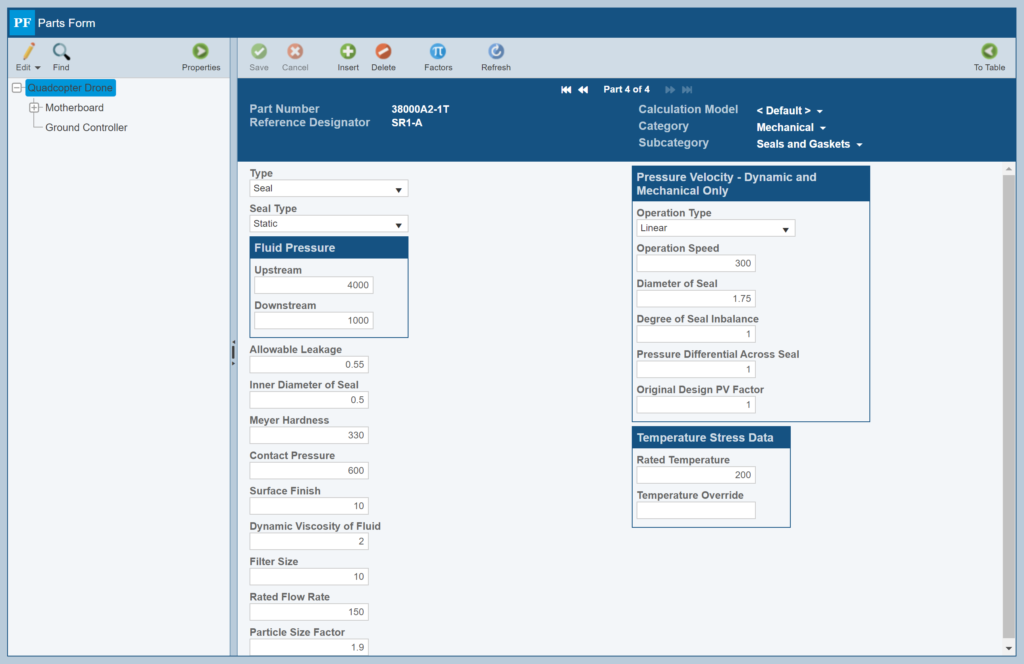

Because usage for each mechanical component type can vary across applications, the NSWC-11 models take operating conditions and material properties into account for failure rate calculations. The appropriate factors vary depending on the part being modeled but can include aspects like misalignment, loading factors, viscosity, and material hardness.

Example NSWC-11 Mechanical Failure Rate Calculation

An example Failure Rate Model for Gaskets and Static Seals per the NSWC-11 standard is:

λSE = λSE,B * Cp * Cq * Cdl * Ch * Cf * Cv * Ct * Cn

where λSE is the failure rate of a seal in failures per million hours.

For the equation above, the following list describes the variables:

- λSE,B is the base failure rate of seal, 2.4 failures/million hours

- The C multiplying factors consider the effects of the following on failure rate:

- Cp – fluid pressure

- Cq – allowable leakage

- Cdl – seal size

- Ch – contact stress and seal hardness

- Cf – seal smoothness

- Cv – fluid viscosity

- Ct – temperature

- Cn – contaminants

Relyence 2022 Release 1 adds on support for the NSWC-11 Mechanical calculation model to Relyence Reliability Prediction.

The data parameters and equations used vary based on the specific mechanical equipment that is being modeled. As you can see from the above example, some of the equation models in NSWC-11 take several input factors that contribute to the overall failure rate equation. Relyence Reliability Prediction comes with built-in default values for all its computations, so you are not required to know all the associated data inputs and multiplying factors to compute a failure rate and MTBF. Additionally, you can set your own defaults if you prefer. As you gather more device data, you can then go back and update your analysis to continually refine your reliability prediction.

Relyence 2022 Release 1 now offers full support for the NSWC-11 prediction standard to our Reliability Prediction package. Additionally, because prediction standards vary in the devices modeled, the environments supported, as well as various other features, Relyence Reliability Prediction allows you to use multiple standards within one Analysis. This important benefit allows you to efficiently model the components of your system and ensure your reliability prediction analysis is accurate and complete.

Introducing SmartSuggest for AIAG & VDA DFMEAs

We are proud to introduce another unique-to-Relyence feature to significantly improve your Failure Mode and Effects Analysis process – FMEA SmartSuggestTM! FMEA SmartSuggest helps to ensure that your FMEA data remains synchronized throughout your Analysis Tree hierarchy. As the name implies, this new feature suggests and displays appropriate FMEA data for use in your DFMEA Worksheet. From the SmartSuggest panel, you can see recommended data suggestions and then choose those that are most appropriate for your analysis.

SmartSuggest can be used with any built-in or custom DFMEA Worksheet templates, and can be especially effective for AIAG & VDA based-FMEAs.

FMEA SmartSuggest Example

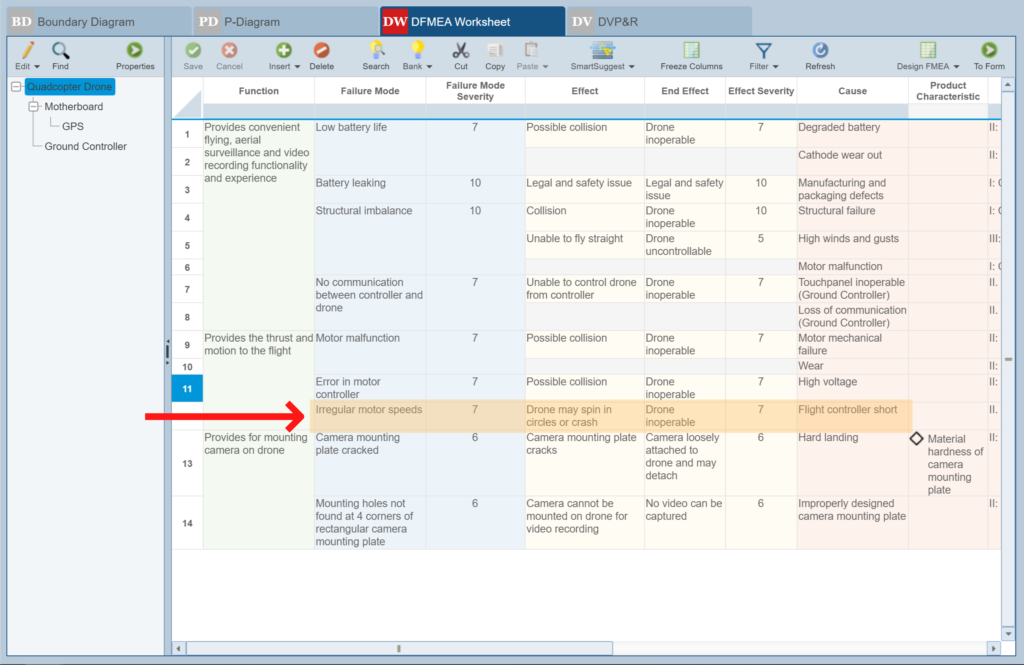

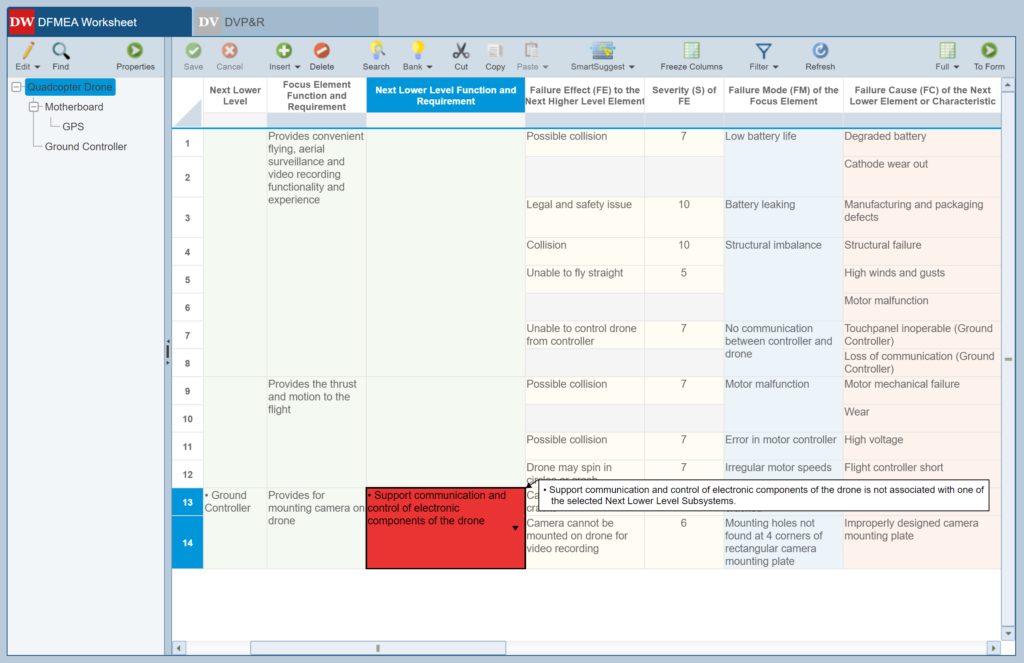

The easiest way to explain this aspect of FMEA SmartSuggest is with an example. For our example case, consider a FMEA based on a Quadcopter Drone. At the top level of our FMEA, we have identified a potential Failure Mode of “Irregular Motor Speeds” with a corresponding Cause of “Flight controller short”.

Failure Mode and Cause information on the DFMEA Worksheet for the top-level Quadcopter Drone tree item.

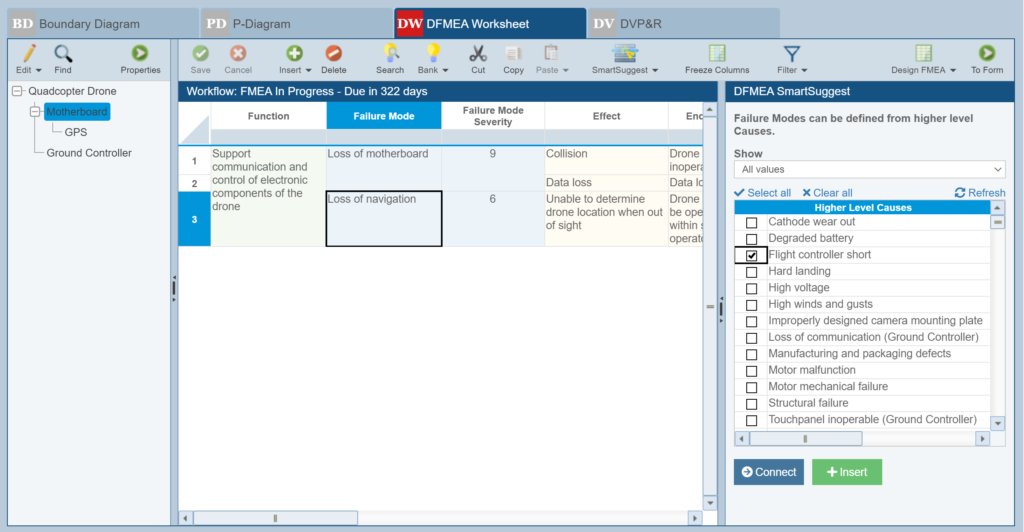

After the completion of the Quadcopter Drone FMEA Worksheet, we move down to the next lower level FMEA Worksheet for analysis – in this case the Motherboard. We can see that several Failure Modes and related data have been entered. To ensure that all appropriate FMEA data from higher levels is captured on the FMEA Worksheet, we can engage the FMEA SmartSuggest Show Suggestions feature from the toolbar.

Use FMEA SmartSuggest’s Suggestions panel to insert FMEA data from higher-level Analysis Tree items.

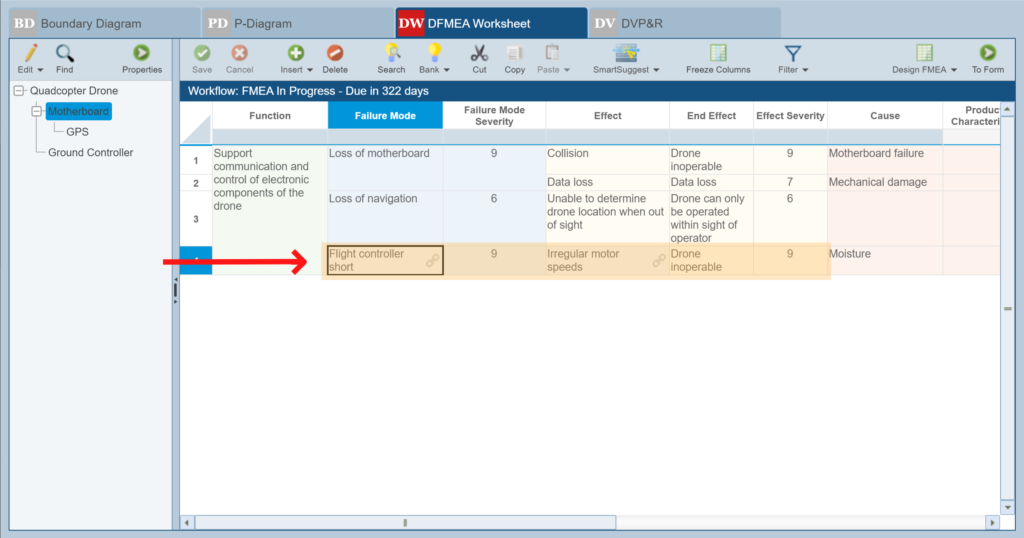

Upon review, we identify that “Flight controller short” is another appropriate Failure Mode so we insert that into the Worksheet. Similarly, we can add the higher-level Failure Mode “Irregular Motor Speeds” as an Effect at the Motherboard level.

Failure Mode and Cause data from the Quadcopter Drone FMEA Worksheet inserted as Effect and Failure Mode data on lower level Motherboard DFMEA Worksheet.

Once added, these records at the Motherboard level are connected to the data at the Quadcopter Drone level. So, any changes made to the Quadcopter Drone FMEA Worksheet will be reflected on the Motherboard FMEA Worksheet. This is one example of how FMEA SmartSuggest ensures that you are capturing all appropriate FMEA data across all Worksheets.

Identifying mismatched data with FMEA SmartSuggest

In addition to its helpful suggestion panel, FMEA SmartSuggest also includes the Highlight Warnings feature. This capability allows you to see warnings when FMEA data is not in sync across Worksheets. With SmartSuggest’s Highlight Warnings feature, any unmatched data will be highlighted so you can easily make necessary corrections. SmartSuggest will highlight your data field in red to indicate a mismatch, enabling you to ensure FMEA consistency.

FMEA SmartSuggest’s Highlight Warnings feature can be used to provide a visual indicator of mismatched FMEA data.

Taking advantage of both the Show Suggestions and Highlight Warnings SmartSuggest abilities ensures your FMEAs are as complete and accurate as possible. FMEA SmartSuggest’s Show Suggestions enables you to maintain consistency across your FMEA Worksheets. With Highlight Warnings, you can easily see and correct any data inconsistencies. You can choose to use each these FMEA SmartSuggest features independently or in conjunction with one another.

The innovative and useful FMEA SmartSuggest offers a unique approach for keeping your FMEA data synchronized throughout your Analysis Tree hierarchy.

With SmartSuggest, we continue our drive to make Relyence FMEA the most powerful and useful tool to perform your Failure Mode and Effects Analysis. In each of our past few releases, we have added at least one new and innovative feature towards achieving this goal. From recently added features like Boundary Diagrams, FMEA Data Autoflow, and Failure Direct Connect, to flagship Relyence FMEA features like Knowledge Banks, and now with FMEA SmartSuggest, the advantages of using Relyence FMEA over Excel or any less capable tool continue to add up.

Enhancements for Support of AIAG & VDA FMEAs

In addition to FMEA SmartSuggest, Relyence 2022 Release 1 includes a number of new capabilities in Relyence FMEA to better support the most recent AIAG & VDA FMEA standard.

Robust Handling of FMEA Product Characteristics

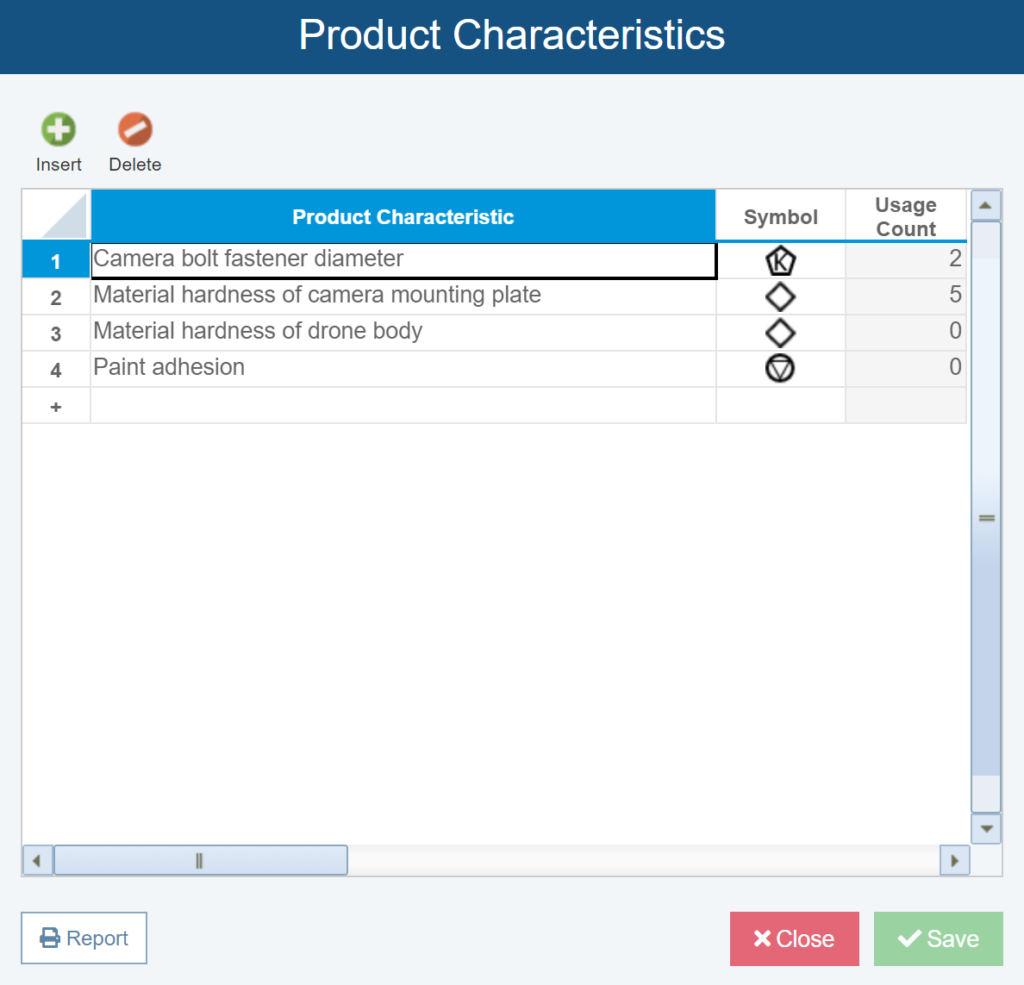

A Product Characteristic is a specific element of focus in FMEA. Product Characteristics represent identifiable features or traits of an element under analysis – for example, weight, hardness, and composition. The list of characteristics depends both on the system under analysis and how its functional requirements have been defined. Product Characteristics can also be referred to as Special or Critical Characteristics and are a key element of focus in the latest AIAG & VDA FMEA standard.

Product Characteristics in FMEA are often associated with a specific symbol in addition to Characteristic description. These symbols make analysis more efficient by providing an easy visual tag that often confers a specific meaning – for example, certain symbols may have a higher level of importance assigned to them. Thus, these high importance Characteristics are easily identified visually by their symbol in the FMEA Worksheet.

In Relyence 2022 Release 1, you can now define and use Product Characteristics in a one-to-many relationship with Causes in your FMEA Worksheets. Each Characteristic chosen is displayed with its associated symbol. Relyence comes with several built-in symbols to choose from or you can upload your own.

In addition, Relyence 2022 Release 1 introduces a new Product Characteristic Report option that generates a list of FMEA Effects that are related to each Product Characteristic. This report can include one or all of your defined Product Characteristics and all FMEA types that include related Effect data.

Define Product Characteristics and their associated Symbols from the Configure menu for use at the Cause-level on FMEA Worksheets.

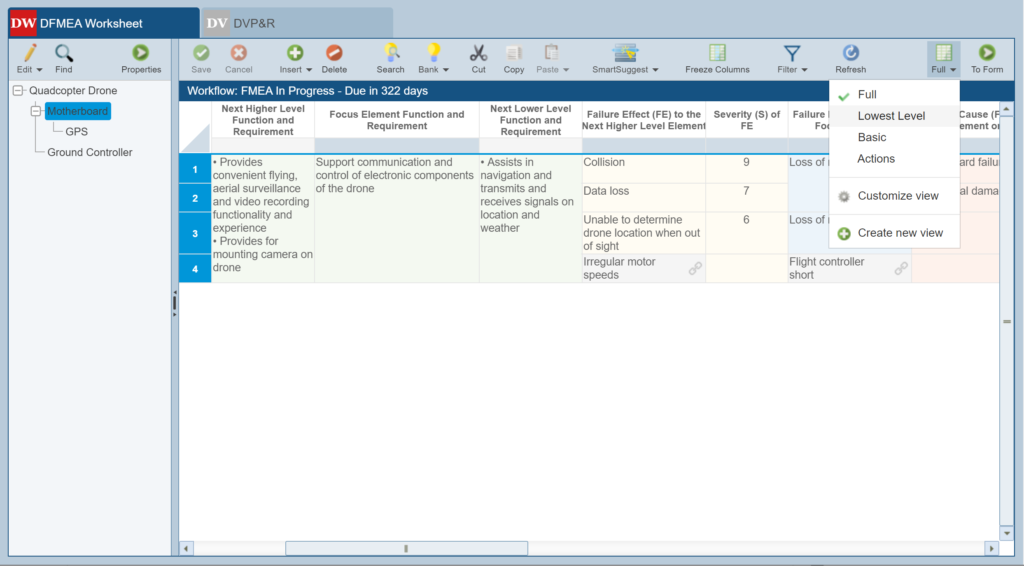

New! Updated AIAG & VDA Worksheet Template

Relyence 2022 Release 1 includes an updated AIAG & VDA FMEA template to better support the Worksheet formats shown in the most recent AIAG & VDA FMEA Handbook . This template can be selected when creating new FMEA analyses in Relyence. Updates to this FMEA template include:

- DFMEA columns have been updated to match the layout shown in the AIAG & VDA standard. For example, the field Failure Effect (FE) to the Next Higher Level Element has been moved to be shown to the left of the field Failure Mode (FM) of the Focus Element.

- A new default View has been added to DFMEA. This view is called Lowest Level and is designed to be used when performing DFMEAs on the lowest level subsystems in your tree structure. This special view supports the AIAG & VDA requirements noted for the lowest level items in your product hierarchical breakdown.

The AIAG & VDA FMEA template in Relyence 2022 Release 1 has been updated to better support the Worksheet formats defined in the most recent AIAG & VDA FMEA Handbook.

Relyence RBD New Capabilities

Relyence 2022 Release 1 introduces new enhancements to Relyence RBD that include both improved diagram management and calculation capabilities.

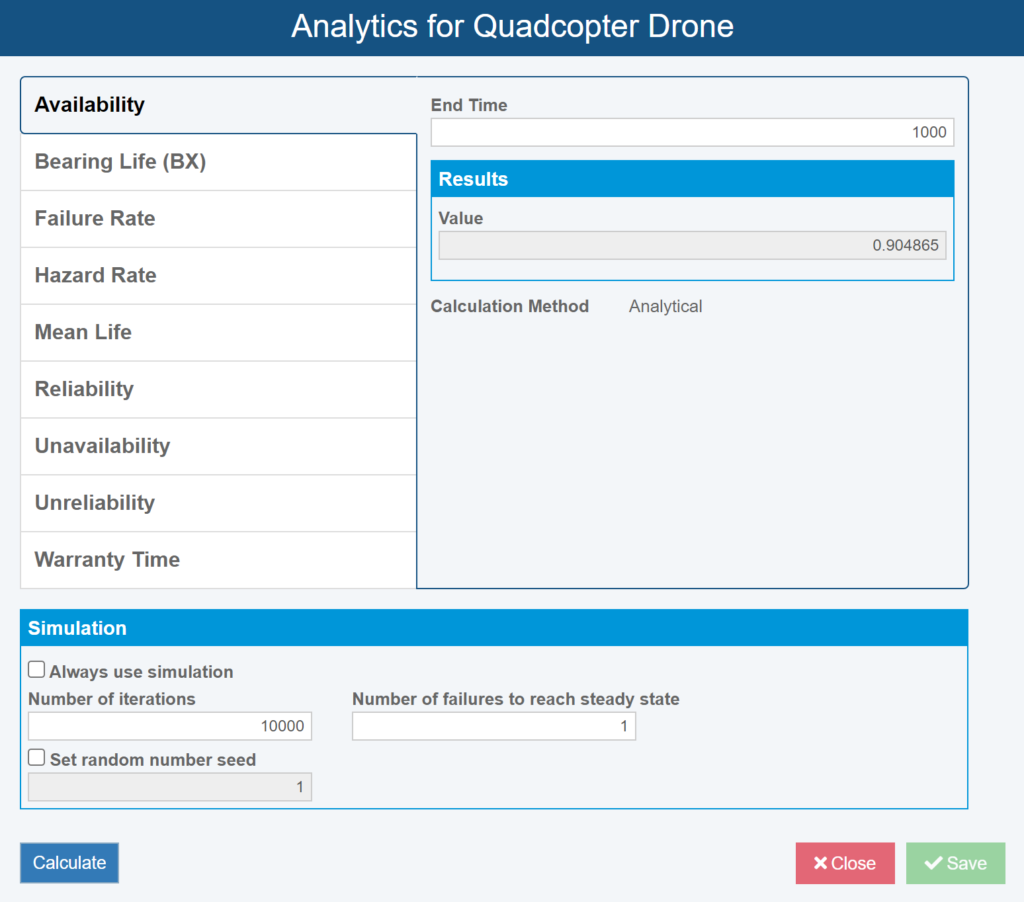

RBD Analytics Calculator

Relyence RBD now includes an Analytics calculator that can be used to calculate various RBD metrics. Metrics available for calculation include Availability, Bearing Life (used to calculate B10 Life), Failure Rate, Mean Life, Reliability, Warranty Time, and more.

Relyence RBD’s smart calculation engine will calculate the metrics using analytical methods, Monte Carlo simulation techniques, or a combination of the two. In addition, the Analytics calculator allows analysts to choose to always use simulation if desired.

Relyence RBD now includes a built-in Analytics calculator to compute point-based metrics for your diagrams.

Support for RBD Libraries

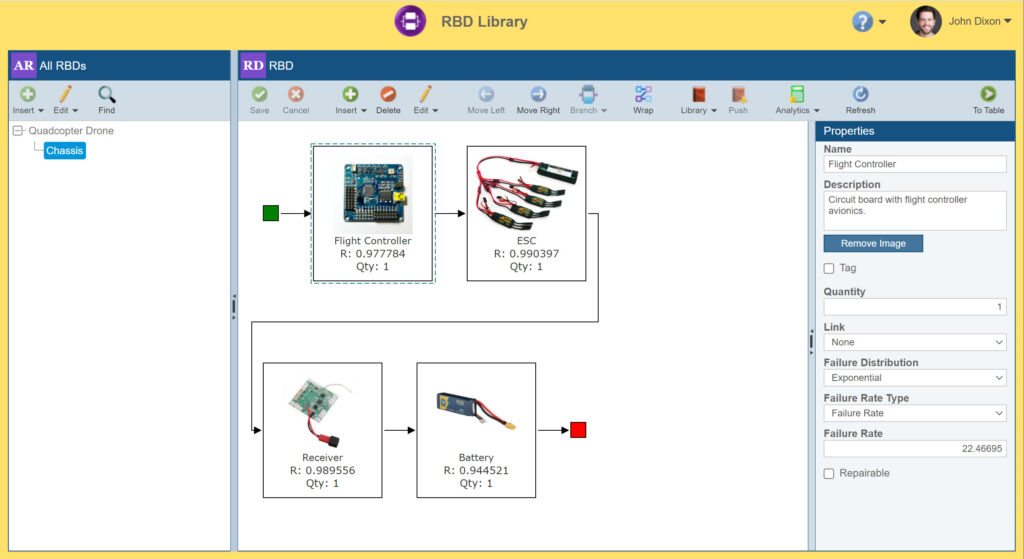

Depending on the system being modeled in RBD, diagrams can quickly become very complex and difficult to manage. To ensure efficient and effective management for accurate analysis, Relyence 2022 Release 1 introduces libraries for data management.

RBD Libraries

Relyence RBD Libraries allow you to save entire diagrams and all included data for reusability and management. For example, you may have a certain group of components or a subassembly that is used across several products in the same configuration. RBD Libraries allow you to easily save and reuse this component group wherever it is required.

RBD Block Libraries

When building RBDs, the individual components that make up your system are represented by blocks in the diagram. Depending on the complexity and level of detail required in your analysis, these individual blocks can represent anything from individual passive components to subassemblies purchased from third party vendors. RBD Block Libraries allow you to save a collection of defined blocks for easy reuse. By providing a database of commonly used blocks, Block Libraries allow efficient construction of your RBDs and ensure accuracy and consistency in your system modeling analyses.

These exciting new additions allow you streamline your RBDs for consistent and well-managed analyses.

RBD Block and Diagram Libraries allow for efficient management of your Reliability Block Diagram data.

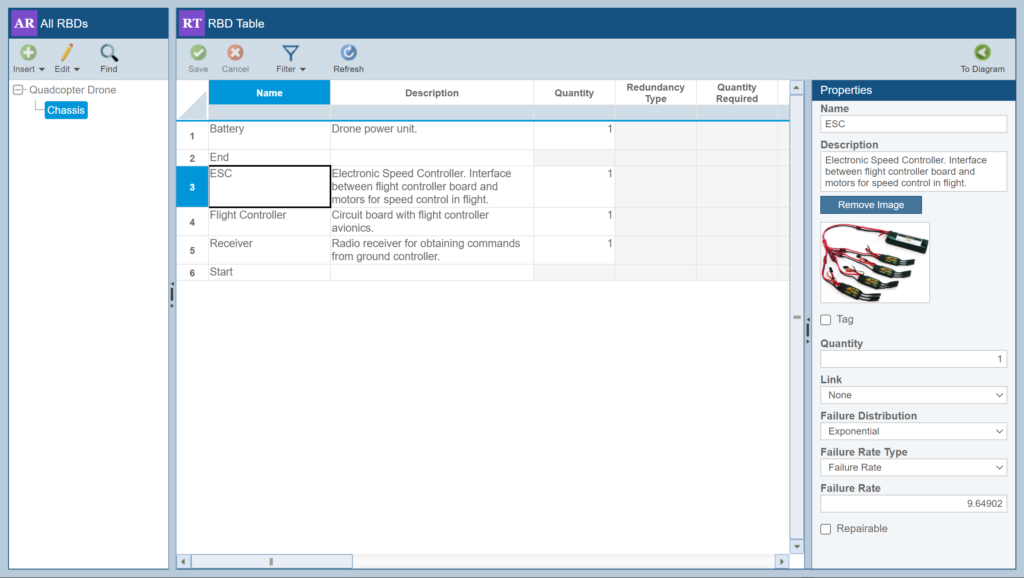

RBD Data Table View

Relyence 2022 Release 1 also includes a new table view of the blocks that make up your RBD. The RBD Table provides a quick, at-a-glance overview of all your RBD data including block Name, Description, and Failure and Repair model as well as redundancy information for blocks and junctions. The RBD Table allows quick access to a summary of your RBD blocks that provides a useful overview of your system and allows for efficient modification of RBD data parameters. To access the RBD Table, simply click the To Table button in the top-right of Relyence RBD.

The RBD Table provides a useful overview of the blocks in your diagram and allows for efficient modification of RBD data parameters.

Analysis Filtering Features

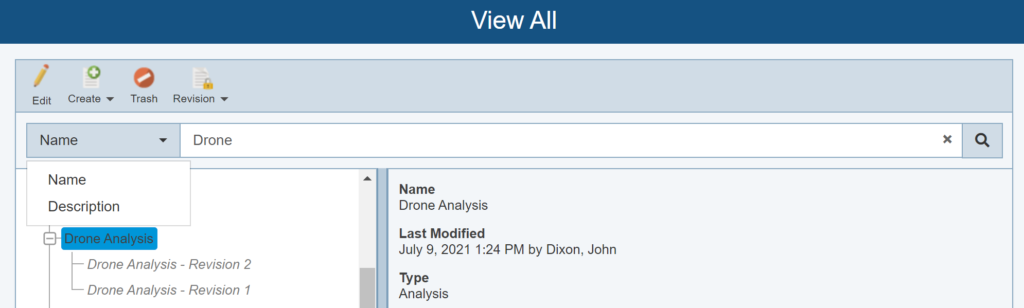

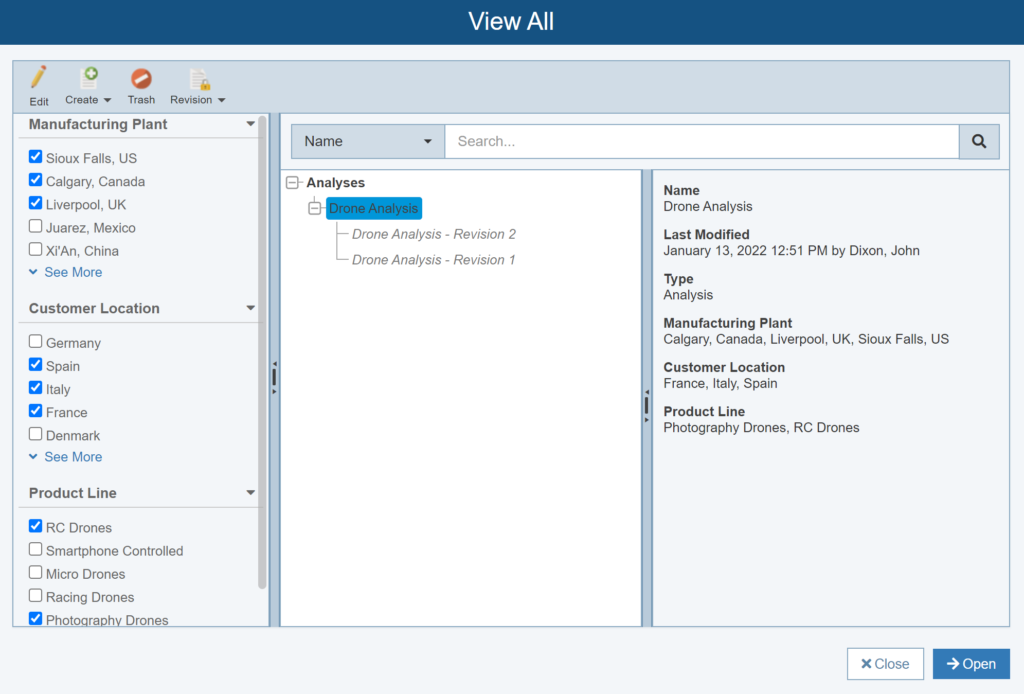

Relyence 2022 Release 1 introduces powerful new features to help you manage your Analyses and quickly locate Analyses using customizable categorizations.

The newly updated View All feature includes a Search bar that allows you to search your Analyses by Name or Description.

You can now search your Analyses by Name or Description from the updated View All feature.

In addition, Relyence 2022 Release 1 adds on support for configurable Analysis Categories for analysis filtering. Think of these like the checkbox filters that you can apply when you are shopping online. Let’s say that, after performing your FMEA on a coffee maker, you decide you need a new coffee maker so you head to Amazon to check the deals that are available. You may quickly find that there are too many options to look through! However, using the checkbox lists in the sidebar, you can filter the options by capacity, type, etc. to narrow down what you are looking for. Analysis Categories operate in the same way by allowing you to set the Categories and options that you’d like to associate with each Analysis.

Analysis Categories Example

For example, you could set lists up for Manufacturing Location, Product Line, Country, etc. to choose from for each Analysis. You can then define the details for the custom Categories in the Analysis Properties for each Analysis. Then from View All, select the specific Categories of interest to filter the list down to the applicable list of matching Analyses.

Relyence 2022 Release 1 improves on the View All screen by adding Name or Description Searching and customizable and filterable Analysis Categories.

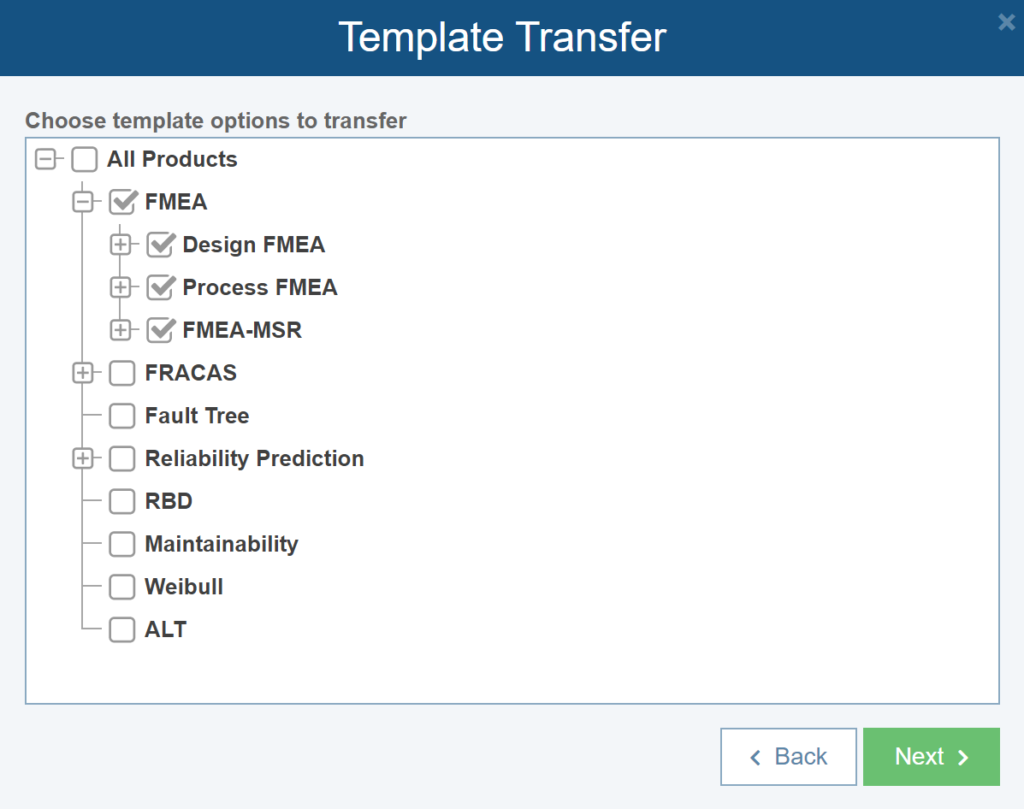

Configuring Analyses Based on Templates

New as part of Relyence 2022 Release 1 is an extremely helpful and powerful new feature that allows you to synchronize your custom Properties and Settings across your Analyses and Knowledge Banks. The new Template Transfer feature allows you to easily make global changes to all the appropriate Analyses when required.

The Template Transfer function provides an easy step-by-step procedure via a Wizard to walk you through the transfer process:

- Select the Analysis which has the Template you want to use.

- Choose the elements of the selected Template you want to transfer. This can be everything from the entire Template to a specific element such as FRACAS Formulas.

- Select the Analyses you want to update with the new Template.

Some ways the Template Transfer can be utilized include:

- Transferring FMEA Risk Criteria configurations.

- Transferring custom FRACAS Incident Formulas.

- Transferring customized fields and views in your Parts Table

- Transferring all customized settings from one Analysis to other Analyses.

These are just a few of the many potential usages of this new feature. This new capability will be a tremendous time saver for those managing a large number of Analyses!

The new Template Transfer feature allows you to easily make product-by-product or global changes to all appropriate Analyses when required.

And more!

In addition to the exciting new capabilities described above, Relyence 2022 Release 1 also includes a long list of additional features designed to further improve our best-in-class software package. Many of these new features are the result of customer suggestions! We are always appreciative of your feedback and we look forward to optimizing our software with the suggestions you make! So, keep them coming!

Some of these new capabilities include:

- In Relyence FMEA:

- The addition of a color-coded Workflow Status bar in Relyence FMEA that shows the current Workflow Step

- The ability to rename PFMEA Process Flow Symbols

- Improved Control Plan Importing capabilities

- The ability to rename Relyence default FMEA types based on your requirements

- Expanded API Support

- In Relyence FRACAS:

- The ability to disable data editing after a Workflow Step has been completed and approved

- An option to automatically calculate custom Formulas on Save

- Expanded API support for FRACAS Subtables

- In Relyence Fault Tree:

- The ability to link Event Failure Data to Reliability Prediction Subsystems or Parts

- A Search option for all dropdown List fields

- Enhancements to User and Group management including the ability to search Users, duplicate Groups, and batch update User information on import

- On Dashboards, the addition of a new FMEA Workflow Breakdown widget and customizable date ranges on various FRACAS widgets

That’s only a few of the many new enhancements that are included in Relyence 2022 Release 1!

Free Trial of Relyence Reliability Software

If you are already a customer of Relyence cloud-based solution, you will see all these exciting new capabilities now! If you are a customer of Relyence On-Premise, you will have access to all these new features as soon as you update your installation.

If you are current Relyence customer, a soon-to-be customer, or are a future customer, please feel free to reach out with your comments. Your valuable feedback helps us to continue achieving our goal of creating the best overall reliability tool software package.

As always, if you would like to check out these new features, or any of the capabilities of the Relyence software tool suite, you can sign up for completely free trial. No hassle, no strings, just register here and put us to the test! Or call today to speak to us about your requirements or schedule a personal demo at your convenience.