The beginning of 2023 comes with another exciting new release from Relyence! Our latest version, Relyence 2023 Release 1, includes a variety of new and powerful features that will help take your reliability and quality analyses to the next level. Relyence 2023 Release 1 continues to expand on our commitment to providing you with best-in-class solutions for your analysis needs, including all new customization capabilities and unmatched innovative features and functions.

New in Relyence FRACAS

Relyence FRACAS is a robust corrective action management platform that helps ensure your processes are in compliance and under control. Relyence FRACAS includes out-of-the-box support for 1-step and 3-step Incident Management, 8D Problem Solving, DMAIC Improvement Cycle, and the PDCA (or Deming) Cycle to get you up and running in no time. You can choose to use one of these built-in templates as-is or take advantage of our customization features to tailor Relyence FRACAS to suit your unique process.

Introducing Selectable Workflow!

Relyence 2023 Release 1 introduces a new Selectable Workflow feature to Relyence FRACAS that expands on our already powerful customizable Workflow capability. With Selectable Workflow, you can define and use multiple Workflows within your FRACAS. This enables you to choose which Workflow works best for individual Incidents or Problems. This adaptability provides new, unparalleled Workflow flexibility. A few examples of how this can be used include:

- If you use the 8D process for problem resolution, you may find that it is not necessary to complete the full 8D procedure for all reported issues. For example, you may have issues that can be closed out after Step D4: Root Cause is completed. With the new Selectable Workflow feature, you can set up two Workflows to use – the full 8D process and a “modified 8D” that only includes steps D1, D2, D3, D4, and D8. For issues that can use the modified 8D procedure, the Change Workflow function allows you to easily switch from the default 8D process to the modified one.

- Different process methodologies can be used within your FRACAS. This can be useful in cases where you have multiple teams that prefer different methodologies. Or, you may have individual issues that progress through a different methodology based on an internal criterion. For example, with the new Selectable Workflow, you can create Workflows for 8D, PDCA, and DMAIC and then select from a mix of Workflows as needed within your FRACAS.

With Selectable Workflow, you can define multiple Workflows to use in your FRACAS.

How to Set Up Selectable Workflow

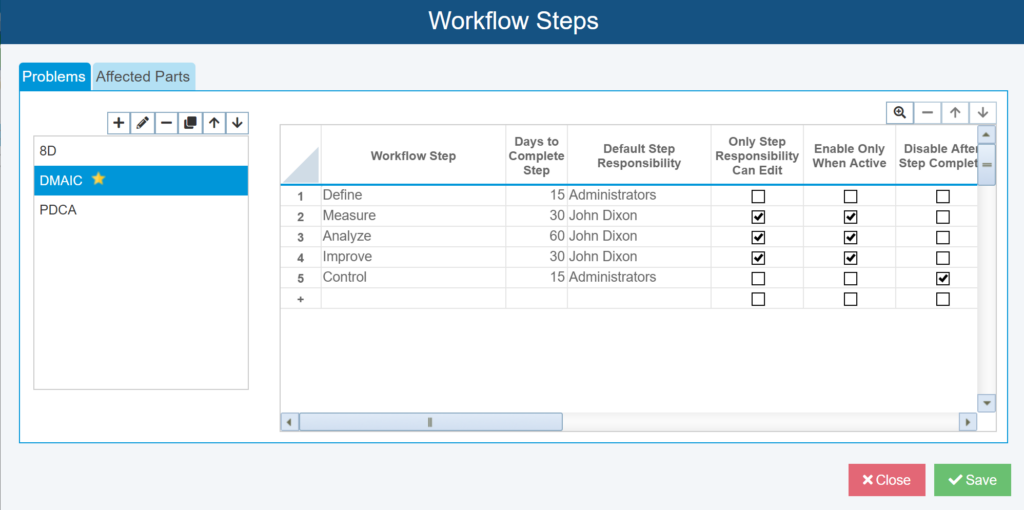

To set up Selectable Workflows, click Configure > Workflow > Steps from the sidebar. From there, you can choose to Add, Edit, Delete, Copy, or Reorder Workflows. Using the Edit (pencil) button, you can choose your default Workflow (indicated by the yellow star), which is the Workflow that will be used unless another is selected.

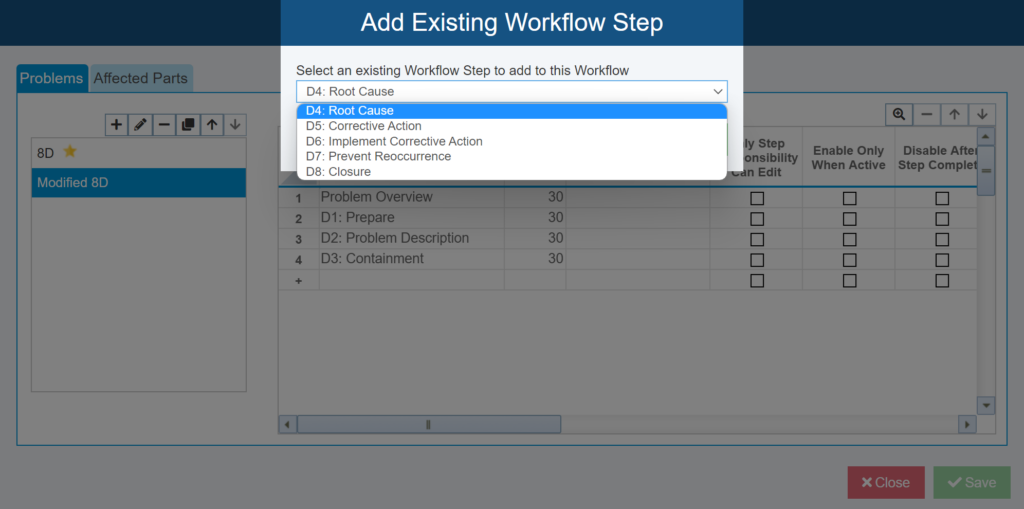

You can then define the Steps for each Workflow along with their Responsibility, Approval, etc. There is also a handy “Add Existing Workflow Step” feature that allows you to easily duplicate a previously defined Workflow Step from another Workflow into the new Workflow.

Use the “Add Existing Workflow Step” feature to easily add in existing Workflow Steps from other Workflows.

Selectable Workflow Example

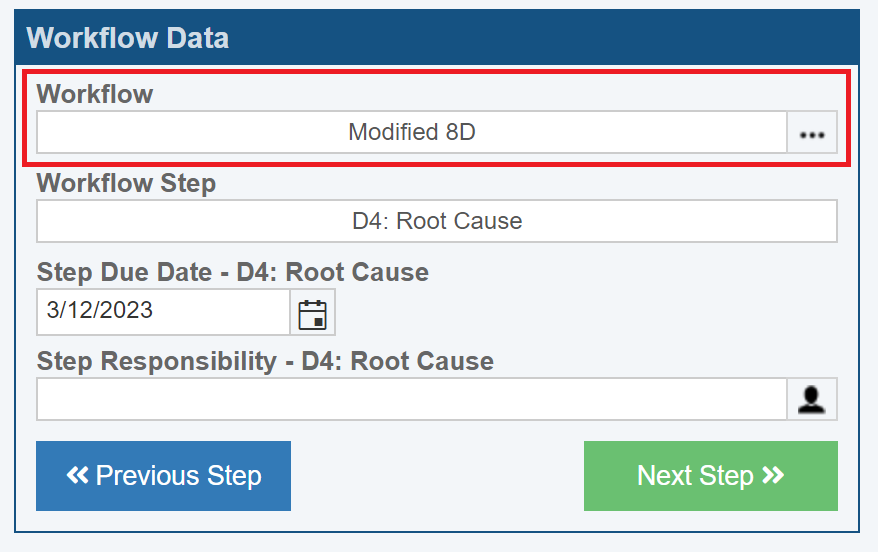

Let’s consider an example of losing the ability to accurately control the drone’s altitude using the full 8D and modified 8D processes outlined above. In this case, we begin our investigation using our default full 8D Workflow. Once this issue has progressed to Step D4: Root Cause, it is determined that the Root Cause is related to a previously investigated calibration issue on the flight controller unit. This previously known Root Cause has already been fully investigated and the appropriate Corrective Actions have been taken, so this new issue can be moved directly to Step D8: Closure. To make the change, we simply click Workflow selector button and update the Workflow from 8D to Modified 8D.

Change Workflow enables you to easily change the Workflow for individual Incidents and Problems.

Using Selectable Workflow with Formulas for Streamlined Process Control

To automate your FRACAS Workflows, you can use Selectable Workflow and Formulas to create an efficient, streamlined process. The new Selectable Workflow feature includes the ability to select the Workflow for an Incident or Problem based on a Formula. By choosing Workflow as the Result Field in your FRACAS Formula, you can then choose the criteria for Workflow selection.

For an example use of this powerful capability, let’s assume our company is a manufacturer of automotive electronic parts and its products can be grouped into three product lines – multimedia unit parts, speed and proximity sensors, and electronic starter units. The FRACAS teams associated with these products lines work independently and they each prefer to use a different process management methodology. The multimedia team uses the PDCA approach, the speed and proximity sensor group prefers 8D, and the electronic starter team uses DMAIC. Upon issue entry, the associated product line is selected. Using the Formula feature, the appropriate Workflow can be set based on the designated product line. In this example you can see how different Workflows can be seamlessly handled within your FRACAS by using Selectable Workflow in conjunction with Formulas, allowing your teams to work smoothly and efficiently.

Dependent Lists

Relyence 2023 Release 1 introduces the new and highly useful Dependent List capability. Dependent Lists allow you to set up dropdown lists where the values shown are dependent on the list item selected in another dropdown list.

For example, you could set up dropdown lists of Manufacturing Location, Product Line, and Product. With Dependent Lists, the choices in the Product Line list can vary based on the Manufacturing Location list item selected. Similarly, the choices in the Product list can be based on the Product Line list item selected.

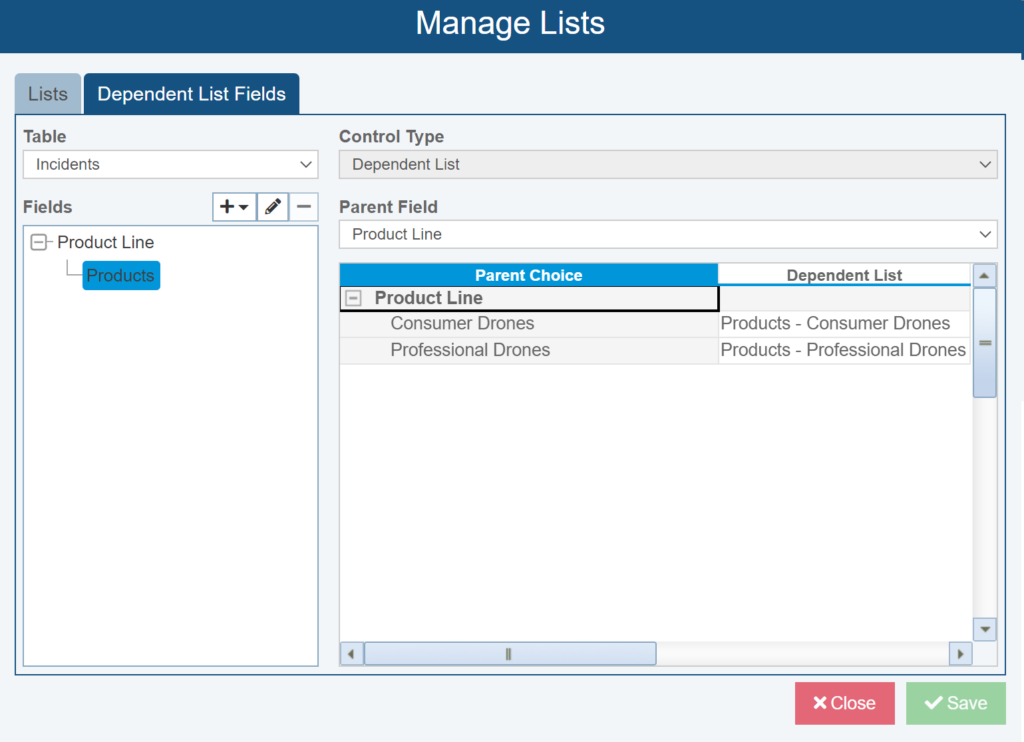

Dependent Lists are set up from the Manage Lists capability. To access Manage Lists, click the Manage Lists icon in the toolbar when customizing your FRACAS Tables or Forms. The Dependent Lists tab allows you to set up your list dependencies.

You can set up your Dependent Lists using either a top-down (parent to child) or bottom-up (child to parent) strategy. Using the top-down method, select the Parent List and select Add New Dependent List from the Add (+) icon dropdown menu. This enables you to create a new Child List. Using the bottom-up approach, select the Child List, and select “Dependent List” as the Control Type to indicate that this is now a child list dependent on another list. Then select the appropriate Parent List it is attached to.

Dependent List Example

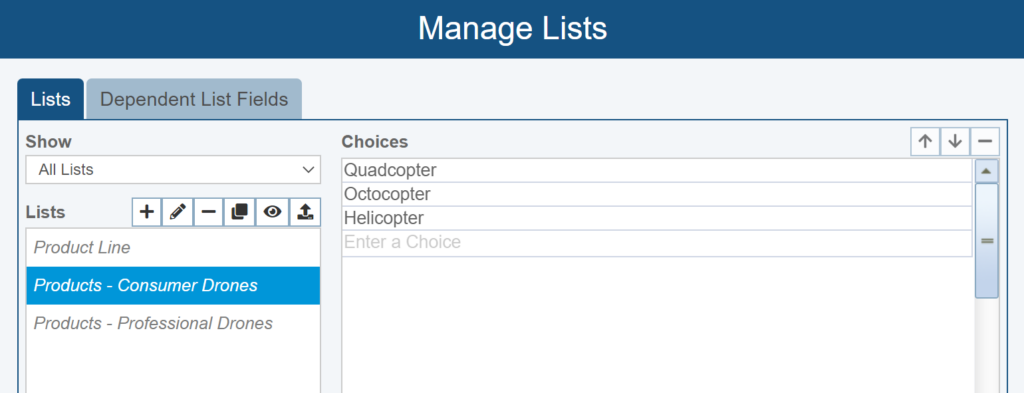

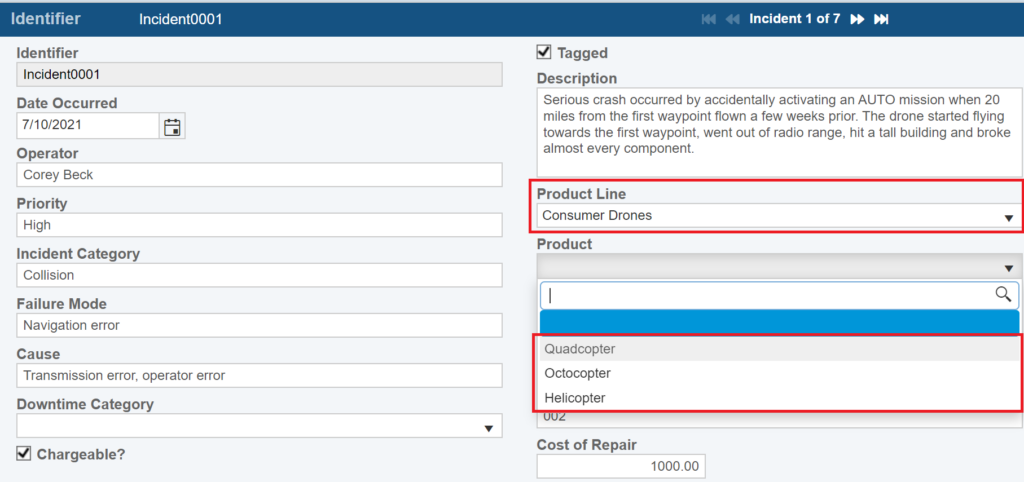

As an example of Dependent List setup, we will look at how to configure a list of Products that are dependent on Product Lines. In this case, let’s assume our company is a manufacturer of Drones with two main Product Lines of Consumer Drones and Professional Drones. Within the Consumer Drones line, we have Products of a Quadcopter, Octocopter, and Helicopter and within the Professional product line we have Racing, Agriculture, and Cinematography Drone models.

In this case, we begin by defining our three Lists: Product Line which consists of Consumer Drones and Professional Drones, and then the two Product type Lists.

Next, on the Dependent Lists Fields tab, we establish the dependency between our Lists. In the Dependent List table, we define the appropriate Child dependent Lists based on the Parent List choices:

Now, as we are completing our FRACAS, we will see only the applicable Products based on the Product Line list item selection:

New in Relyence FMEA

Relyence FMEA continues to prove itself as the best-in-class tool for your Failure Mode & Effects Analysis needs. Offering out-of-the-box support for DFMEA, PFMEA, FMEA-MSR, and MIL-STD-1629A FMECA, including Boundary Diagrams, P-Diagrams, Process Flow Diagrams, DVP&R, and Control Plans and with powerful features like the Knowledge Bank and Foundation FMEAs, SmartSuggest, AutoFlow, it is obvious that you can rely on Relyence FMEA! With Relyence 2023 Release 1, we continue to enhance Relyence FMEA’s robust feature set with the goal to ensure that your FMEA process is as efficient and consistent as possible.

Cohesive Handling of FMEA Symbols

Relyence 2023 Release 1 introduces the ability to define Symbols for use across your DFMEAs, PFMEAs, and FMEA-MSRs. Symbols can be used for various purposes, including highlighting critical or key items, classifying various risk metrics, or any other purpose you may require. They are most commonly used in relation to Product and Process Characteristics in DFMEA and PFMEA.

Global Symbol List

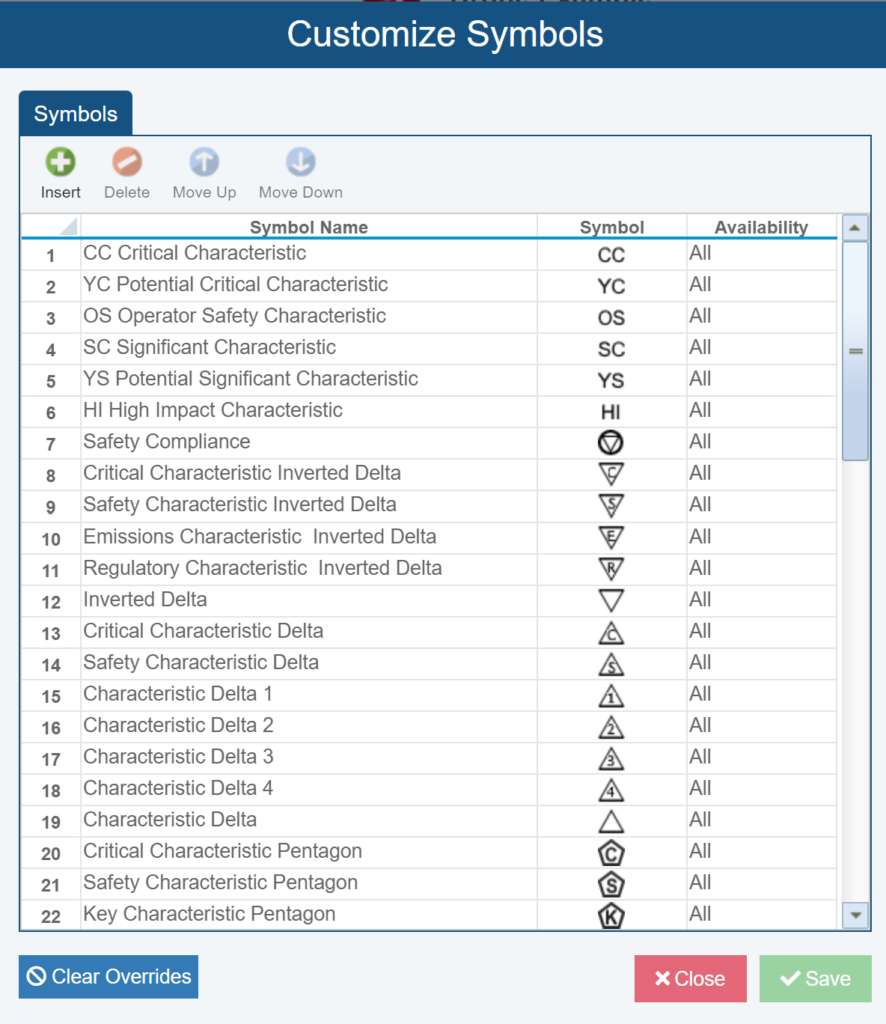

Relyence FMEA comes with a built-in set of commonly used Symbols that can be used out-of-the-box or customized to your needs. The Symbols Editor is a central databank for all the Symbols you can use across your FMEA elements.

To define your list of Symbols, select Configure > FMEA > Symbols from the sidebar. You can use the built-in Symbols as-is, customize them as needed, or add any needed custom Symbols. If appropriate, you can also choose if Symbols can be used across all FMEA types or in DFMEA, PFMEA, or FMEA-MSR only. Moving Symbols up or down in the list sets their significance. Relyence FMEA assumes that Symbols at the top of the list are higher in importance than those lower on the list. Therefore, in cases where multiple Symbols exist for one FMEA item, the Symbol nearer to the top of the list will take priority.

The Symbols Editor is a central databank for all the Symbols you can use across your FMEA elements.

Using Symbols with FMEA Characteristics

In FMEA, there are two types of Characteristics commonly used: Product and Process Characteristics.

Product Characteristics are specific elements of focus in FMEA and represent identifiable features or traits of the element under analysis. They can also be referred to as Special or Critical Characteristics. Example Product Characteristics include weight, hardness, and material composition.

Process Characteristics, used in PFMEAs, are the various process factors that can have an effect on the output of a process step. Process Characteristics examples include torque, flow rate, and tool temperature.

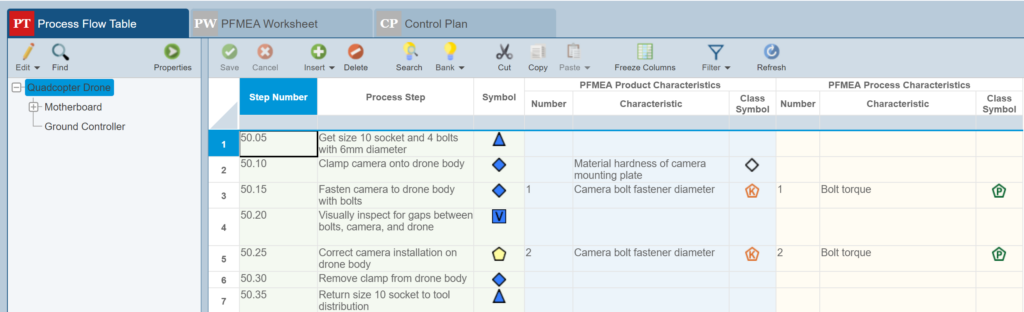

Symbols can be associated with both Product and Process Characteristics. Symbols can be used to provide a specific meaning or indicator to a certain Characteristic. Sharing Characteristics and their Symbols across FMEA types ensures that high priority items are consistent and accounted for across your FMEA documents. For example, certain Symbols can be used to define Characteristics of high importance that can then be easily identified and traced through your FMEA visually.

In Relyence 2023 Release 1, Symbols can be applied to Product and Process Characteristics from Configure > FMEA > Characteristics.

With Relyence 2023 Release 1, Symbols can be applied to Product and Process Characteristics for efficient analysis and as easy-to-read visual indicators.

Product Characteristics

Now in Relyence 2023 Release 1, you can choose to define different symbols for each Product Characteristic across your various FMEA types. You can choose to share Product Characteristics across your DFMEAs, PFMEAs, and FMEA-MSRs, however you can also choose to use specific Symbols in each FMEA type, if appropriate.

For example, let’s assume you perform both DFMEA and PFMEA on your product. On both the DFMEA and PFMEA Worksheets, you have a Product Characteristic field. In your DFMEA you deem a specific Product Characteristic as “Potential Critical Characteristic” and select the Symbol accordingly. However, as you perform your DFMEA, you recognize that the failure is not sufficiently handled through the design. In this case, you want to change the Product Characteristic Symbol to “Critical Characteristic” in your PFMEA to ensure that the failure is properly handled. With the ability to define Product Characteristic Symbols independently by FMEA type, this is easily accomplished in Relyence FMEA 2023 Release 1.

Process Characteristics

In Relyence 2023 Release 1, Process Characteristics and associated Symbols can now be defined and used across the Process Flow Table (PFT), PFMEA Worksheet, and Control Plan (CP). Additionally, Relyence PFMEA’s always-in-sync capability ensures your Process Characteristics and associated Symbols are kept synchronized across your PFMEA documents.

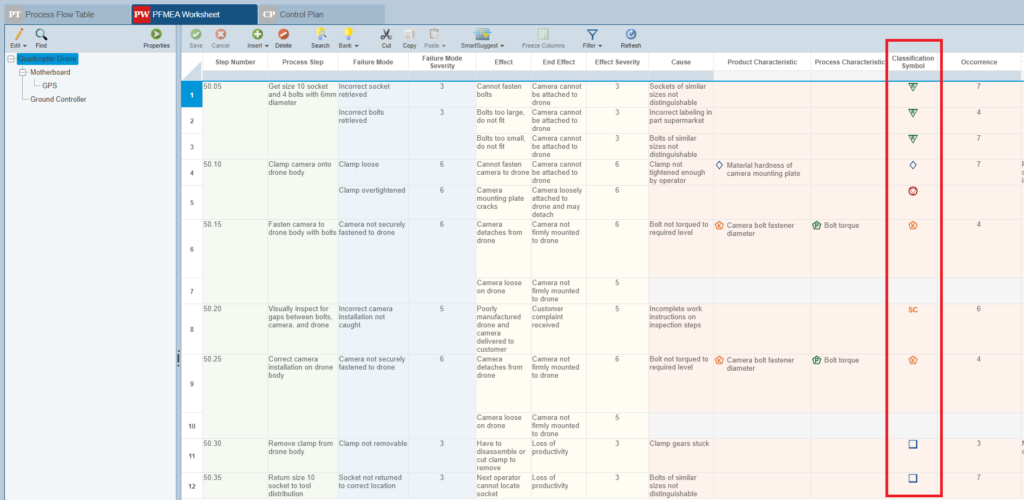

Using Classification Symbols on the FMEA Worksheet

In Relyence 2023 Release 1, you can also now use Symbols directly on your DFMEA, PFMEA, and FMEA-MSR Worksheets with the Classification Symbol field. This field provides a dropdown list of all your Symbols and is searchable by Symbol Name, so you are able to quickly find the appropriate Symbol for use in your Worksheets. If you have Symbols defined for your Product or Process Characteristics, Relyence will automatically populate the Classification Symbol field on your FMEA Worksheet with the Symbol of highest importance.

Symbols can be used on your FMEA Worksheets in the Classification Symbol field.

Assigning Symbols Based on Severity Values

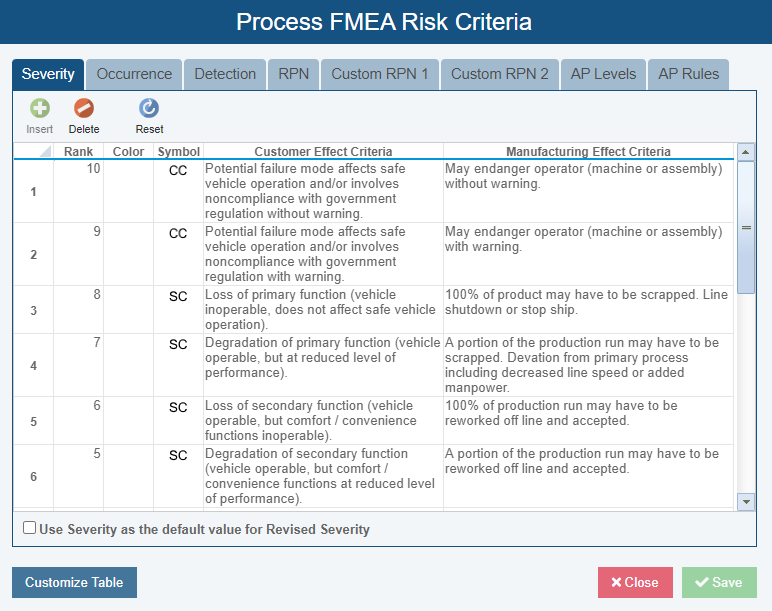

Additionally, Relyence 2023 Release 1 includes the ability to define a Symbol for each Severity value. This allows the Classification Symbol field to be auto-populated based on the Severity value chosen. For example, you could assign the “Critical Characteristic” Symbol to be set all FMEA items with a Severity of 10 or 9. In this case, when the chosen Severity value is 10 or 9, the Classification Symbol field will be automatically populated with the “Critical Characteristic” Symbol.

Included in Relyence 2023 Release 1 is the ability to define Symbols for each Severity.

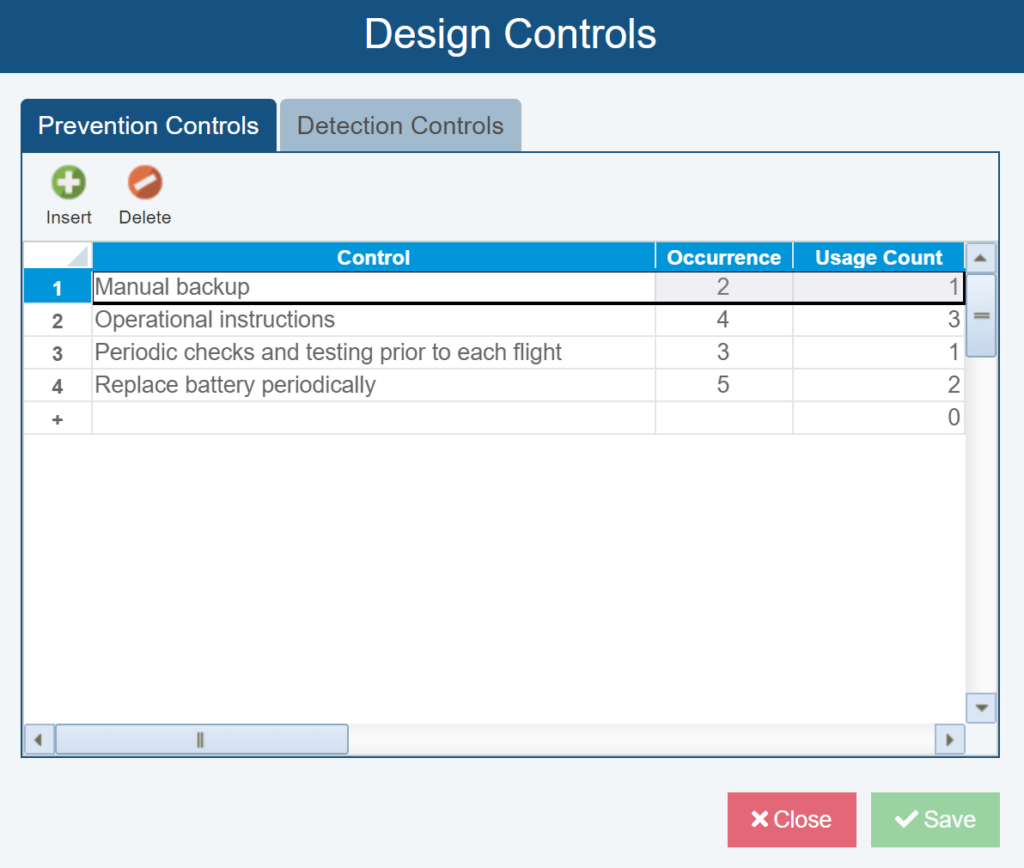

FMEA Occurrence Values Associated with Prevention Controls

Prevention Controls are typically included on Design FMEA (DFMEA) and Process FMEA (PFMEA) Worksheets. The goal of Prevention Controls is to implement methods that avoid a potential failure. Effective Prevention Controls can aid greatly in achieving high system reliability and safety. An example Prevention Control could be an automatic shut-off that initiates if a battery charger’s contact points reach a certain temperature. This shut-off prevents a battery overheating failure.

In Relyence FMEA, you can define a set of Prevention Controls by selecting Configure > FMEA > Controls from the sidebar. Then when performing the FMEA, analysts can select from the list of predefined Prevention Controls that are commonly used. Now with Relyence 2023 Release 1, you can also associate an Occurrence value with each Prevention Control. Occurrence values are an important component for computing RPN (Risk Priority Number) or AP (Action Priority) for risk assessment. When a Prevention Control is selected, the associated Occurrence value is automatically retrieved and entered on your Worksheet, making data entry and risk assessment more streamlined and organized.

You can now associate an Occurrence value with Prevention Controls for controlled and consistent RPN and AP calculations used for risk assessment.

New in Relyence RBD

Relyence RBD offers a comprehensive platform for modeling complex systems, including those that incorporate redundancy, and leverages powerful analytical calculation methods and Monte Carlo simulation techniques to compute a wide array of metrics. Relyence 2023 Release 1 introduces expanded calculation features to Relyence RBD’s high-powered computation engine.

Cold Standby Redundancy on Blocks Linked to Subdiagrams

Relyence 2023 Release 1 introduces the capability to model blocks set to Redundancy Type of Cold Standby that are linked to subdiagrams. In a Cold Standby redundant configuration, the backup units are inactive and cannot fail until a primary unit failure forces the backups to come online. Subdiagrams in RBD provide a way to easily reuse pieces of your RBDs and offer a mechanism to manage large diagrams. Now, combining these organizational benefits with the ability to model Cold Standby on subdiagram blocks means you have the ability to calculate complex redundant configurations in an intuitive and well-structured way.

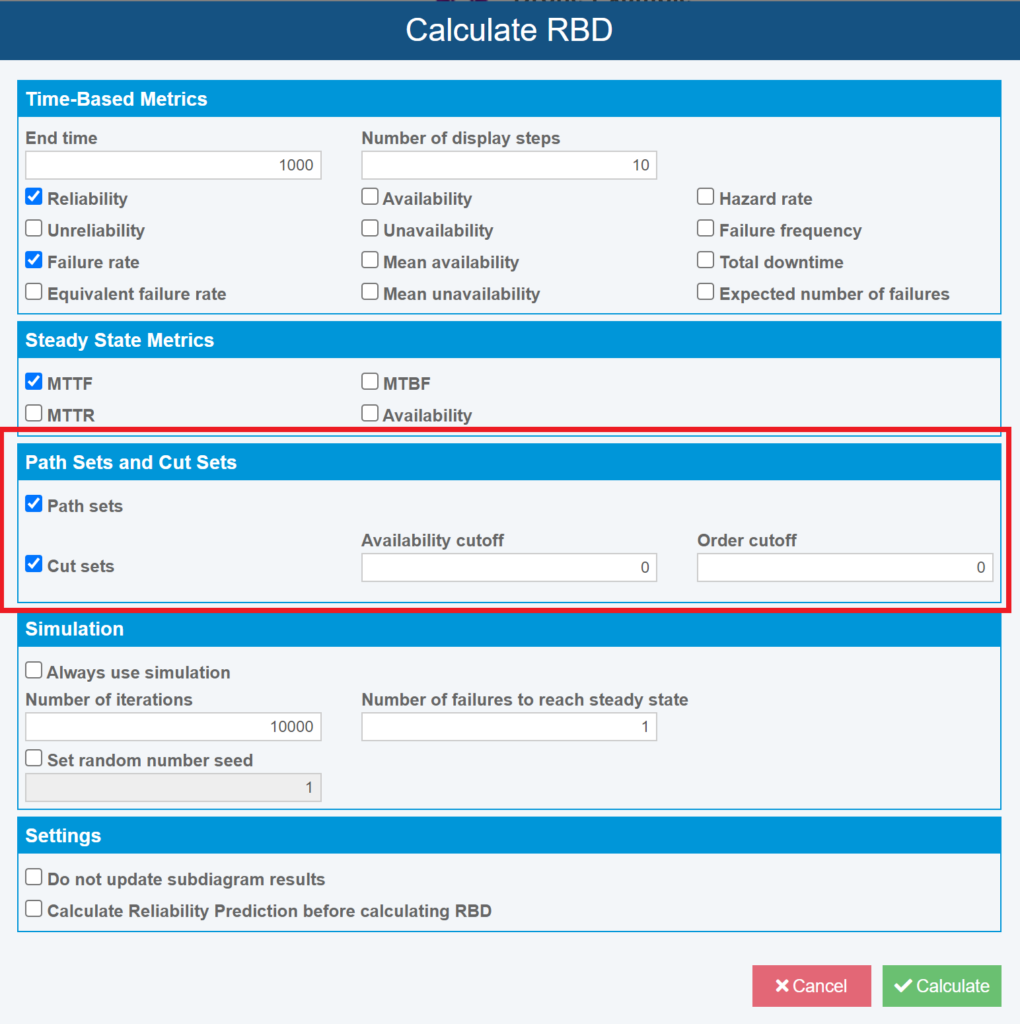

Path and Cut Sets on Cold Standby Redundant Configurations

Additionally, Relyence RBD now includes the ability to calculate Path Sets and Cut Sets for Cold Standby redundant configurations. Path sets in RBD show you the blocks that are required for successful system operation – that is, path sets allow you to easily see a path to system success by providing a visual indication of the components required. On the other hand, cut sets are a collection of blocks that, if failed, will cause the entire system to fail. Cut sets can provide an indicator of your system’s most critical components that can cause system failure. Now in Relyence 2023 Release 1, Path Sets and Cut Sets can be calculated on Cold Standby configurations arranged as branching structures and those that are linked to subdiagrams. To calculate Path and Cut Sets, simply select the appropriate calculation options and any desired cut-offs from the Calculate RBD dialog in Relyence RBD.

Now in Relyence 2023 Release 1, Path sets and Cut sets can be calculated for Cold Standby redundant configurations.

New in Relyence Fault Tree

Relyence Fault Tree provides a flexible and robust framework for your Fault Tree Analysis (FTA) requirements. Its intuitive interface allows you to construct well-organized and visually appealing diagrams and its back-end mathematical engine can be used to calculate numerous risk metrics, including minimal cut sets (MCS), unavailability, and importance measures. Relyence 2023 Release 1 introduces several new capabilities to Relyence Fault Tree to ensure you achieve comprehensive system analysis.

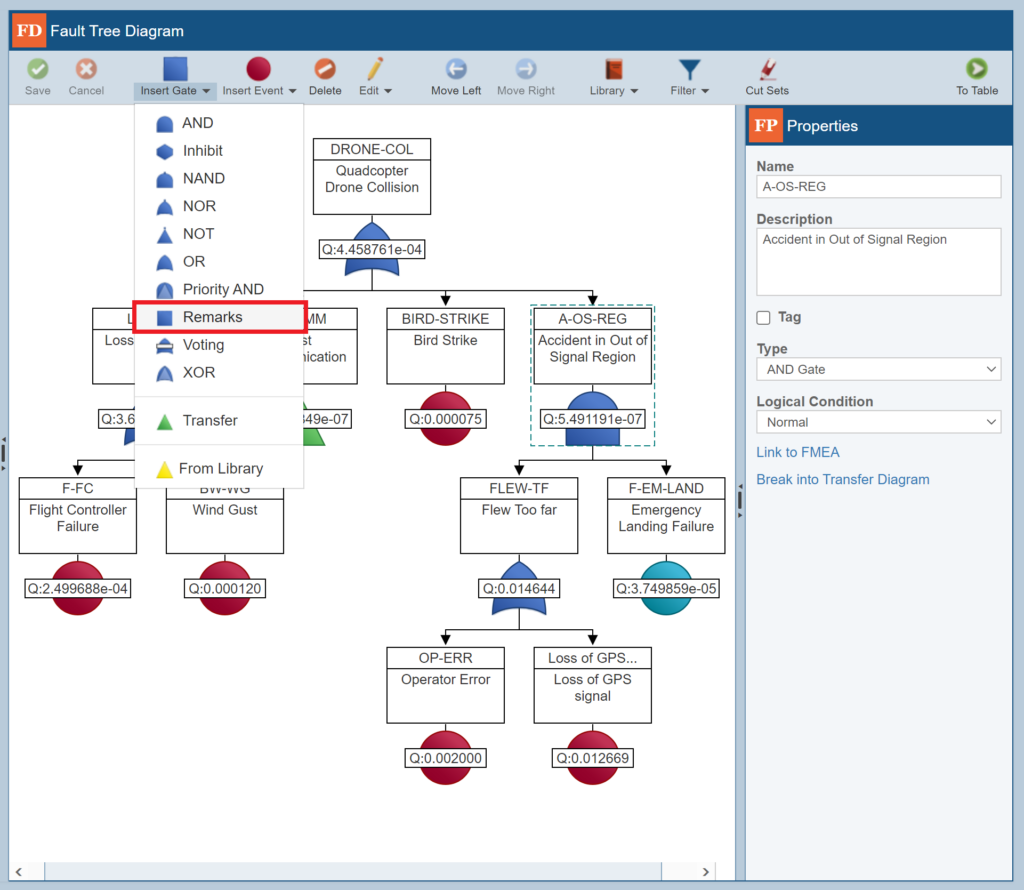

Remarks Gate

Relyence Fault Tree now includes a Remarks Gate that allows you to add more information directly onto your Fault Tree Diagram. Remarks Gates are also often used to aid in creating more optimal diagram layouts.

Remarks Gates do not affect Fault Tree calculations, so they can be used freely without affecting your analysis results in any way. To use Remarks Gates, simply select the Remarks option from the Insert Gate button in the top toolbar of Relyence Fault Tree.

Remarks Gates can be used to display additional information on your FTA or to help optimize diagram layout.

Custom Gate and Event Data Fields

Now in Relyence Fault Tree, you can define custom text-based data fields to display on your Gates and Events. Custom data fields can be used to store additional information that may be needed on your FTA diagrams and can be seen in the Properties pane of your Gates and Events and on the Fault Tree Table. Also, you can use the Import option to import data directly into these fields if you have data in an outside system you want to add to your FTA.

To use custom fields, click Properties in the sidebar of Relyence Fault Tree, then select the Custom Fields tab. You can then choose the label used for each field as well as its display size.

View Usage on Transfer Gates and Repeat Events

Relyence 2023 Release 1 introduces a new View Usage capability to Transfer Gates and Repeat Events. This allows you to easily view and navigate to all instances of a Transfer Gate or Repeat Event from your Fault Tree Diagram. To open View Usage, simply select the Transfer Gate or Repeat Event you are interested in, then click the View Usage link from the right-hand Fault Tree Properties pane.

New Statistical Event Models

Relyence Fault Tree now supports an expanded selection of statistical Input Models for the Events in your diagram. These expanded options ensure your event behavior and FTA diagrams are modeled precisely and that calculated metrics provide an accurate depiction of the real-world performance. Now included in Relyence 2023 Release 1 are three additional statistical Event Input Models: Normal, Lognormal, and Uniform.

And more!

In addition to the exciting new features highlighted above, Relyence 2023 Release 1 also adds several notable enhancements to the Relyence Studio reliability and quality software tool suite. Some of these include:

- New List Manager enables you to easily view and edit all your Lists in one place and includes a View Usage feature to show where your Lists are used

- New Filter by Branch option in Knowledge Banks

- New option to Delete or Ignore Knowledge Bank Push updates

- New reporting option in PFMEA to include a Process Flow Symbol key

- New capability to sort your Analysis Tree by Subsystem Name

And that’s not all! Along with everything listed above, you will also find even more additional enhancements in Relyence 2023 Release 1!

Free Trial of Relyence Reliability Software

If you are a customer of the Relyence Cloud-Hosted solution, you will see all these exciting new capabilities now! Or, if you are a customer of the Relyence On-Premise solution, you will have access to these new features as soon as you upgrade your installation.

If you are evaluating reliability tools, sign up today for your completely free trial to check out our new features as well as all the capabilities of our powerful reliability and quality tool suite. No hassle, no strings, just register here and put us to the test! Or call today to speak to us about your requirements. Or schedule a personal demo at your convenience.

If you are current Relyence customer, a soon-to-be customer, or a future customer, please feel free to reach out with your comments and suggestions. Your valuable feedback helps us to continue achieving our goal of creating the best-in-class reliability tool software package!