Foundation FMEAs

Foundation FMEAs offer an approach for the management of your FMEA data to aid in reusability, retain lessons learned, maintain FMEA data consistency, and much more. Foundation FMEAs are a key element of the AIAG & VDA standard, entitled “Failure Mode and Effect Analysis – FMEA Handbook”, a widely accepted source for guidance of the FMEA process.

What are Foundation FMEAs?

Foundation FMEAs, also known as shell, core, template, or master FMEAs, encapsulate FMEA information from prior analyses for reuse. If established and used properly, Foundation FMEAs allow you to access and retrieve data from previous Failure Mode and Effects Analyses for current use.

Foundation FMEAs can also be a storage system for FMEA data that applies across systems or processes. In this case, Foundation FMEAs may also be referred to as generic, baseline, or best-practices FMEAs. Foundation FMEAs may also be organized to be used along product lines or similar systems – sometimes referred to as a family FMEA.

However you choose to establish and use Foundation FMEAs, the main objectives remain the same: consistency, reusability, and knowledge retention. They enable you to work efficiently and ensure that your FMEAs are well-organized and well-managed. By streamlining your FMEA process, Foundation FMEAs help you meet your continual improvement objectives.

Benefits of Foundation FMEAs

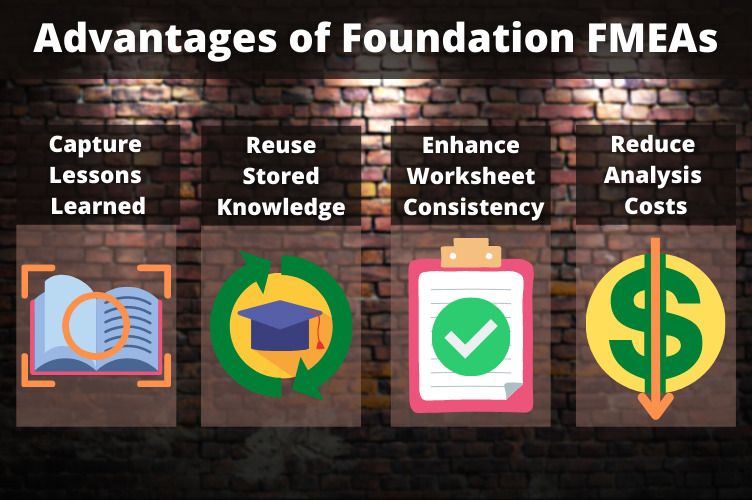

There are many benefits to employing Foundation FMEAs as part of your FMEA practice. Four main advantages are:

- Lessons learned. Foundation FMEAs offer the ability to leverage knowledge from prior designs or product revisions into current or next-gen designs, providing a solid foundation for continual improvement efforts. They also ensure analysts have easy access to all prior analysis data, allowing for an effective means of knowledge transfer.

- Data reusability. When elements of prior generation designs are being reused, the FMEA information can be retrieved and reused with ease if stored in Foundation FMEAs. Or, you can retrieve prior information as a baseline starting point to help complete your current analysis.

- FMEA consistency. The effective use of Foundation FMEAs enables team members to all be drawing data from the same source. This means that reused items can be kept in sync. So if new information is found, it can be added to the Foundation FMEA and all referencing FMEAs can be updated accordingly.

- Cost reduction and business efficiency. Once Foundation FMEAs are in place, the amount of time required to complete your FMEAs can be significantly reduced. Overall, the completion of your FMEA risk analyses is faster, more effective, and more consistent once Foundation FMEAs are in use – a clear winner for business efficiency, and, therefore, inherent cost reduction for these tasks.

What is the AIAG & VDA FMEA Handbook?

The AIAG & VDA FMEA Handbook provides general guidance for implementing a robust FMEA methodology for all FMEA types including DFMEAs, PFMEAs, and FMEA-MSRs. Published in cooperation between two widely recognized automotive industry groups, the AIAG & VDA standard is applicable to any organization performing design and process-based FMEAs.

The handbook introduces new concepts such as Foundation FMEAs, the 7-Step Approach for FMEAs, and Action Priority (AP) for risk assessment.

The 7-Step Approach for the FMEA process includes:

- Planning and Preparation

- Structure Analysis

- Function Analysis

- Failure Analysis

- Risk Analysis

- Optimization

- Results Documentation

Action Priority, or AP, is a systematic approach to FMEA risk level assessment based on Severity, Occurrence, and Detection rankings. It assesses risks as High, Medium, and Low. AP can be used in place of or in conjunction with Risk Priority Number (RPN).

Benefits of COTS FMEA Software vs. Excel Templates

Oftentimes, FMEAs are performed using a widely available, commonly used software tool such as Excel. While seemingly cost effective, the disadvantages of using generic tools for Failure Mode and Effects Analyses becomes quickly apparent once moving beyond a very basic analysis.

A few of these disadvantages are data inconsistency across spreadsheets, lack of organization, uncontrolled analyses, and no support for a team-based approach. Additionally, centralized and important features such as Foundation FMEAs are not supported using these generic software tools.

By contrast, COTS (Commercial Off-the-Shelf Tools) FMEA software platforms are designed specifically to offer a solid framework for well-managed failure analyses. They provide a multitude of benefits that enable to you to establish an organized approach for your FMEA process. Some also have built-in support for the more complex aspects you desire in a FMEA tool, such as support for Foundation FMEAs.

Read more on the many benefits of COTS FMEA software tools, such as Relyence FMEA, over Excel templates.

Maintain Compliance with Relyence FMEA and Foundation FMEAs

The AIAG & VDA FMEA Handbook has gained acceptance across a broad spectrum for FMEA implementation guidance. For those organizations wanting to support the methodology described in the AIAG & VDA Handbook, the adoption of Foundation FMEAs is a central part of that effort. Importantly, requirements in the automotive sector, such as IATF 16494, and the Ford Customer-Specific Requirements (CSR) related to it, designate the need for Foundation FMEAs as part of the FMEA process. Foundation FMEAs have therefore gained swift traction in the automotive supply chain, and are also gaining widespread support in quality-centric organizations across all industry sectors.

In addition, adherence to compliance requirements means that FMEA Worksheets, Control Plans (CP), and Process Flow Diagrams (PFD) must remain in sync. Misalignment of these documents is a common finding in audits, often resulting in NCRs (Non-Conformance Reports). Manually ensuring these documents remain in sync and fixing findings found in audits is time-consuming and costly. One of the key benefits of Relyence FMEA’s innovative always-in-sync capability is that it enforces the alignment of your FMEA elements at all times. Many organizations have realized their ROI (Return on Investment) in Relyence FMEA software within a single audit cycle due to this feature alone.

With its built-in capability for Foundation FMEAs and the always-in-sync feature to keep FMEA documents aligned, Relyence FMEA provides support for your key quality and compliance requirements.

Relyence FMEA: Best-in-class FMEA Software

Relyence FMEA provides a robust platform for your Failure Mode and Effects Analyses. Wrapping an impressive array of features in an elegantly designed and intuitive framework, Relyence FMEA offers a best-in-class solution.

Supporting the most commonly used FMEA standards, including AIAG and VDA-based FMEAs, Relyence FMEA has become the go-to software tool for analysts worldwide. Relyence FMEA has built-in support for Foundation FMEAs through our innovative Knowledge Bank, as well as a host of features to make your FMEA process organized and effective. Check out some of the Relyence-only innovations you’ll find in Relyence FMEA such as Workflows & Approvals, Autoflow, SmartSuggest, and Failure Direct Connect by delving into the details described on our Relyence FMEA product page.

Or sign up today for our completely free, no hassle, no install, no download trial! If you would prefer a personalized tour of Relyence FMEA, schedule an interactive demo that provides a product overview and time for Q&A.

Feel free to contact us any time to discuss your needs. We can offer guidance and advice based on our years of experience in the fields of reliability, quality, and safety engineering.