Watch a video walkthrough of A Real World FMEA Example in Six Steps.

Jump to: Step #1: Define the Function | Step #2: Determine the Failure Modes | Step #3: Analyze the Effects | Step #4: Describe the Causes | Step #5: Establish the Recommended Actions | Step #6: Implement the Recommended Actions | Conclusion

For many people (including those of us here at Relyence!), coffee is a critical part of our morning routine. With it, we’re able to jump start our day, effectively answer emails that came in overnight, organize our tasks, and look forward to a productive day. Without it, we’ll just say we’re not as effective, and leave it at that!

Have you ever thought about how the design of your coffee maker helps ensure you get that same cup of coffee you expect every morning? In fact, so well designed that we can be half asleep and still successfully make our coffee?

Let’s take a look and see how Design FMEA (Failure Mode and Effects Analysis) can be applied to a very critical function of your coffee maker: dripping hot water onto the coffee grounds.

Steps of Our FMEA Example

The basic goal for our FMEA will be to analyze how this function can fail and what we can do to mitigate that failure. To do this, we’re going to:

- Define the Function

- Determine the Failure Modes of that Function

- Analyze the Effects of each Failure Mode

- Describe the Causes of each Failure Mode

- Establish the Recommended Actions for each Cause to mitigate that failure

- Implement our Recommended Actions

Step #1: Define the Function

When defining a Function, we have to be specific. This allows us to narrow our focus and break down our FMEA. For this example, our Function will be: Hot water is dripped over the coffee grounds.

Here, we are assuming that water is already in the coffee maker, the water is already hot, and the coffee grounds are also in the coffee maker. You can use FMEA to assess the failure of these additional Functions if you wanted to broaden the scope of your FMEA. For this example, we are concentrating on this one specific Function. The flexibility of FMEAs enables you to breakdown your Functions in as much detail as you prefer.

Step #2: Determine the Failure Modes

Now that we have our Function, what are our Failure Modes? First, let’s assume that our coffee maker has a movable arm that dispenses the hot water. Note that your coffee maker may not have this exact design, but many do.

Now, we could define many Failure Modes for this Function. Let’s just focus on one Failure Mode for now: The arm is not positioned over the coffee grounds.

At this point, you can see where we’re heading. We’re not getting our coffee! But let’s formalize this with FMEA Effects.

Step #3: Analyze the Effects

We can list many Effects, but again we’ll just examine one for simplicity: Coffee is not prepared.

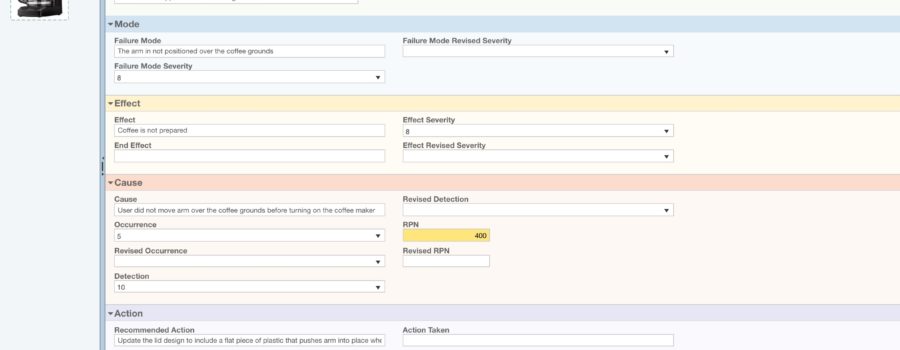

Next, we have to assign a Severity to this Effect. Severity is one of the components used to assess the risk levels of our FMEA items. Depending on your caffeine addiction, you may think this is a Severity of 10 because you can’t imagine your morning without coffee! We’ll stick to the more objective rules of severity ranking. Using the standard AIAG Severity levels, we will assign our Effect a Severity level of 8. Severity level 8 indicates that this Effect involves a loss in the primary function of the coffee maker.

Note that there is also a Severity to be populated at the Failure Mode level. The Failure Mode Severity is used for the RPN (Risk Priority Number) calculation. Relyence automatically sets the Failure Mode Severity to be the greatest value of all of the Effect Severities. In this example, the Failure Mode Severity level is also an 8.

Step #4: Describe the Causes

Now, we have to analyze our potential Causes for this Failure Mode. We can have more than one Cause listed, but let’s once again focus on one: User did not move arm over coffee grounds before turning on coffee maker.

For each Cause, we also have Prevention and Detection Controls. These describe controls in place to either prevent this Cause from occurring or detect it when it occurs. In our case, we do not have either of these, so we will leave these fields blank.

Next, there are two critical values we have to populate for the RPN calculation: Occurrence and Detection. We will use the rank and criteria from the AIAG standard for these values, as we did for Severity.

For Occurrence, we’ll assign a value of 5 because this happens occasionally.

For Detection, we’ll assign a value of 10 because we do not have any method to detect this Cause when it occurs.

Now, we’re ready to calculate RPN as the product of Failure Mode Severity, Occurrence, and Detection. For this FMEA line item, the RPN is 400 (8 * 5 * 10). Relyence FMEA automatically calculates this for you.

Step #5: Establish the Recommended Actions

The last portion of a FMEA is to define and execute Recommended Actions to reduce Severity or Occurrence, or improve Detection of a FMEA line item. This is a critical portion of the FMEA process and allows you to continuously improve your product.

For this Failure Mode and Cause, what can we do to make sure that the arm is positioned over the coffee grounds before making coffee? Could we update the user manual for the coffee maker? Could we put a sticker on the arm that says “Please place arm over coffee grounds prior to making coffee”? In the first case, we know people don’t read user manuals. In the second case, it’s likely the sticker would peel and fall off after time due to the heat inside of the coffee maker. So neither of these solutions appears to be a good Recommended Action.

What if we added a flat piece of plastic to the lid of the coffee maker that pushed the arm into position when the lid is closed? This would force the arm into the correct position any time that the lid is closed. Also, it’s safe to assume that the user is more likely to remember to close the lid of the coffee maker than move the arm into position before closing the lid.

If you happen to have a coffee maker with a design that includes a movable arm that dispenses the hot water, take a look at the lid. It probably has a small piece of plastic that lines up perfectly with the arm when you close it.

Now, let’s formalize this in our FMEA worksheet. For our Recommended Action, let’s enter: Update lid design to include a flat piece of plastic that pushes arm into place when the lid is closed.

Typical FMEA worksheets allow you to document who is responsible for completing this Recommended Action and when it is due. For this example, this will be my task to do within the next month.

Step #6: Implement the Recommended Actions

Now, let’s skip one month into the future – I have completed my task and I want document my activity and close the loop. For Action Taken, I’ll enter: Flat piece of plastic added to lid that lines up with movable arm when closed.

Because the Recommended Action is complete, I can now assess how much our design change affected product quality. To do this, we still use the Severity, Occurrence, and Detection values; however, we will use the Revised version of these fields.

Effect Revised Severity will remain at an 8 because this failure still results in the loss of the primary function of the coffee maker. Our design change did not change the Severity level of the Effect. Once again, Failure Mode Revised Severity is the greatest Revised Severity value of all the Effects of this Failure Mode. Therefore, the Failure Mode Revised Severity also remains at an 8.

The Revised Occurrence is now 1, in contrast to the original 5. Our design change is a prevention control that eliminated the occurrence of this failure.

The Revised Detection remains a 10 because we did not add any method of detecting this failure.

This now allows us to calculate a Revised RPN of 80 (8 * 1 * 10). From this single design change, we were able to reduce our RPN from 400 to 80! This is a significant drop that means this failure mode is no longer deemed a high risk item. RPN values allow you to comparatively assess risk. You can establish your own risk criteria based on RPN values that best suit your requirements. For our example, we may assess all RPNs over 300 as critical, or high risk, and those below 100 as low risk.

Try Relyence FMEA Software for Free Today!

This is exactly the type of problem reliability and quality engineers strive to solve – how do we ensure we design for reliability and quality? As consumers, we really don’t think all that much about the quality of products we use until we discover it missing. As a manufacturer, however, once our product starts failing in use, it’s an upward battle to regain our customer’s trust. The technical term for this is the COPQ, or Cost of Poor Quality. COPQ is perhaps not as quantifiable as other direct profit and loss metrics, but equally significant. If you are committed to product reliability and quality, check out the free trial of our Relyence toolset today to see how we can help with your quality improvement goals, or contact us for more information.