One of the most well-known ways of estimating product reliability is to calculate its MTBF, or Mean Time Between Failures. This brings up a common question: is MTBF the same as reliability?

The short answer is no, which may surprise you.

If MTBF isn’t the same as reliability, what exactly is it? Is there a relationship between MTBF and reliability? And more importantly, why is MTBF helpful if it isn’t the same as reliability?

Let’s start with some definitions so we can see the difference between MTBF and reliability.

What is MTBF?

MTBF, or Mean Time Between Failures, is the average amount of time between failures of a system. For example, an MTBF of 100 hours indicates that a system, on average, will successfully operate for 100 hours before experiencing a failure.

What is Reliability?

Reliability is defined as the probability that a system will perform its intended function for a specified period of time. For example, a reliability of 0.8 at 100 hours indicates that after 100 hours, there is an 80% chance that the system is still functioning.

How do I convert MTBF to Reliability?

You can probably already start to see the difference between MTBF and reliability. The key difference is that MTBF is the amount of time between failures and reliability is the probability that the system is still functioning at a certain time.

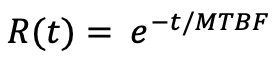

Even though MTBF and reliability are different, you can very easily convert MTBF to reliability by using this equation for exponential distributions:

In this equation:

- e is the mathematical constant approximately equal to 2.71828

- t is the end time, in hours, that you are interested in

- MTBF is expressed in hours

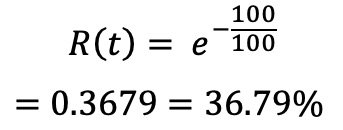

Let’s convert our previous MTBF value of 100 hours to reliability as an example. To make it interesting, let’s also calculate reliability at 100 hours. This will indicate the probability that a system with an MTBF of 100 hours will still be functioning after 100 hours of operation.

Using the above equation:

So, if you have a product with an MTBF of 100 hours, you only have a 36.79% chance that it actually functions for 100 hours!

That seems like an unexpected result, doesn’t it? This quick example might make you start to wonder what exactly is MTBF and how can you use it. Read on and fear not, MTBF is still helpful!

MTBF as an Average

If you have an attention to detail, like many reliability engineers do, you may have noticed one very key word in the definition of MTBF: average.

Let’s say you manufacture circuit boards. If you build one circuit board and sell it, that single circuit board might fail very quickly. Or, it might last for a very long time. Or, the time to failure might fall somewhere in between. There are many variables which can affect how well your circuit boards perform. Some examples include the quality level of the components you procured, manufacturing variability, shipping problems, customers’ misuse, etc. Therefore, it becomes very difficult to determine how long one circuit board will function without failing.

Fortunately, it’s very unlikely that you only manufacture one circuit board. Chances are you manufacture hundreds or thousands of circuit boards, and each circuit board will fail at a different time. With all of those data points, you will start to be able to calculate an average.

That average? That’s your MTBF.

MTBF and an Analogy with the Amazon Rating System

Our favorite analogy for MTBF is the rating stars on Amazon – because we all shop on Amazon!

One of the most important data points that many of us use when deciding whether to purchase an item on Amazon is the rating stars that previous customers have given the product. If one product has two stars and another product has four stars, which one are you going to buy? We bet the one with four stars is already in your shopping cart.

Does that four-star rating mean that the single product you receive will be worthy of four stars? Absolutely not. It might break quickly and deserve a two-star rating from you. Or it might last a lifetime and deserve all 5 stars. But chances are, from the rating shown on Amazon, it will be deserving of four stars.

Take a look on Amazon at any product with four stars and you will see this exact trend. Some customers rated it poorly, some rated it great, and on average, it was rated 4 stars.

This is just like MTBF. An MTBF will let you gauge the lifetime of the average product that you produce. One single iteration of that product may be an outlier from the MTBF, but on a large scale, the lifetime of most of your products will correlate to the MTBF value.

Why Is MTBF Helpful?

MTBF is a helpful metric because it enables you to assess the average lifetime of your product or system.

One of advantages of using MTBF as a measure for reliability assessment is that there are widely used and accepted methods of calculating it. Plus, those analyses can be performed during the design phase of your system before actual manufacturing and deployment. This allows you to evaluate the expected lifetime of your product and address areas of concern ahead of time – saving you both real and reputational costs. Essentially, analyzing MTBF can help you to minimize your cost of poor quality (COPQ).

Additionally, if you have MTBF values for previous products, you can use those values for comparison against a new product you are designing. If you calculate an MTBF for a new product and it aligns with the MTBF of a previous product that your customers gave four or five stars, you know you’re in good company. On the other hand, if you calculate an MTBF for a new product and it aligns with the MTBF of a previous product that your customers gave one star, you know you have some work to do. It’s time to review your design and correct any areas driving your MTBF so you can be confident you are headed for a 5-star rating before your product even arrives in the customers’ hands!

Those are just two benefits of MTBF – there are many more. For more information about MTBF, check out our What Is MTBF? webpage.

Should I use MTBF or Reliability?

You now understand the difference between MTBF and reliability, know how to convert MTBF to reliability, and why MTBF is a helpful metric.

Does this mean that you should use MTBF over reliability, or reliability over MTBF? Not at all! MTBF and reliability are two different metrics used for a similar purpose – to evaluate system design and analyze where improvements can be made.

Both MTBF and reliability are useful metrics, and recognizing their similarities and differences is key to understanding how to apply them for system analysis. Use MTBF and reliability as two more tools in your journey to continued product improvement and success!

The Relyence Suite

Relyence offers a range of software tools to help you to analyze MTBF and reliability. Our Relyence Studio suite combines all our applications into one powerful integrated package. Each product can also be used individually or in any combination you prefer. Our Relyence Reliability Prediction and Relyence RBD packages specifically can be helpful in computing MTBF and reliability, along with an array of additional metrics. Also, Relyence FRACAS, Relyence Weibull, and Relyence ALT can be used to perform reliability calculations.

We also offer completely free, no-hassle, no-strings trials of all our products. Sign up today to see our tools in action, or feel free to contact us for a personal demo.