FMEA Flexibility: Software for all FMEA Types including Design & Process FMEAs, FMEA-MSRs, and FMECAs

Relyence FMEA supports a variety of FMEA types including Design FMEAs (DFMEA), Process FMEAs (PFMEA), Supplemental FMEAs for Monitoring and System Response (FMEA-MSR), Manufacturing FMEAs, Software FMEAs, Services FMEAs, and piece-part FMECAs. Integration across Boundary Diagrams, P-Diagrams, Function and Failure Nets, Process Flow Diagrams, Control Plans, DVP&R, and FMEA Worksheets provides numerous advantages. Relyence’s failure analysis software for design and process FMEAs provides an unparalleled package for failure mode assessment and evaluation.

All-in-One Software for Design FMEA, Process FMEA, FMEA-MSR, and FMECA

Relyence FMEA enables you to effectively organize and manage your Failure Mode and Effects Analyses through an intuitive user interface. Relyence FMEA allows you to perform any type of FMEA you choose:

- Design FMEAs to assess and address failure modes during early or end stage product design, including Boundary Diagrams, P-Diagrams (Parameter Diagrams), Function and Failure Nets, and DVP&R (Design Verification Plan and Report)

- Process FMEAs to analyze and maintain process control objectives, including P-Diagrams, PFDs (Process Flow Diagrams) and PCPs (Process Control Plans)

- Piece-part FMECAs combining failure analysis with quantitative criticality analysis, including integration with the FMD database

- FMEA-MSRs, or Monitoring and System Response FMEAs, to supplement DFMEAs and evaluate product failures during customer use

- Custom FMEAs supporting failure mode analysis any way you choose

Widely Accepted Standards Supported include SAE, AIAG, AIAG & VDA, MIL, and ISO

Offering built-in support for widely accepted FMEA standards, Relyence FMEA enables quick start-up and comprehensive analysis capabilities. Select from the supplied templates for Design FMEAs, Process FMEAs, FMEA-MSRs, and FMECAs supporting SAE J1739 and ARP5580, AIAG methodologies, AIAG & VDA, and MIL-STD-1629A, or customize a template to suit your unique needs. And piece-part FMECAs can be automated with Relyence’s built-in support of the FMD-2016 Failure Mode Distributions database. Relyence FMEA has a number of advantages in your compliance-related activities:

- SAE FMEA Software: With its ranks exceeding 120,000 engineering and technical members, the former Society of Automotive Engineers — now known as SAE International — develops standards aimed at making industries associated with land, sea, air and space transportation — such as the automotive, aerospace and commercial vehicle sectors — safer and more reliable. Using Relyence’s SAE standard compatible FMEA software enables professionals tasked with risk assessment to do their jobs in a highly accurate and efficient manner.

- AIAG FMEA Software: Performing failure mode and effects analysis using Relyence software to meet the standards set by the Automotive Industry Action Group — or AIAG — allows automakers, manufacturers, suppliers, retailers, and service providers to work together toward a more efficient, safe, and resilient supply chain. Founded by the North American automakers Ford, Chrysler, and General Motors, the AIAG’s membership has grown substantially. Today, it includes overseas auto manufacturers such as Nissan, Toyota, and Honda, as well as more than 900 automotive experts who work non-competitively to continually develop best practices in the auto industry.

- AIAG & VDA Software: The AIAG & VDA FMEA Handbook covers Design FMEA (DFMEA), Process FMEA (PFMEA), and Supplemental FMEA for Monitoring & System Response (FMEA-MSR). It also introduces the concept of Action Priority for risk assessment and defines the 7-Step Approach to the FMEA process. Published in cooperation between two established automotive industry groups – AIAG and VDA (Verband der Automobilindustrie, or the German Association of the Automobile Industry) – the AIAG & VDA standard is applicable to a wide range of industries, not just those in the automotive sector.

- MIL-STD 1629A FMECA Software: The Department of Defense standard, MIL-STD 1629A, adds criticality analysis to traditional FMEAs. For this reason, MIL-STD-1629 is used in a wide range of industries and is not limited to military applications. MIL-STD-1629 FMECAs provide the groundwork that give professionals a comprehensive method of failure mode analysis down to individual components within systems.

- ISO Standards Compliance: As one of the largest and most recognized global standardization bodies, the International Organization for Standardization — or ISO — acts in a proactive manner to set standards aimed at supporting the design and manufacture of products that are reliable, safe, and aim for continual quality improvement. FMEAs and FMECAs are often part of an organization’s ISO compliance requirements, and Relyence FMEA software is a vital tool to help to ensure those goals are achieved.

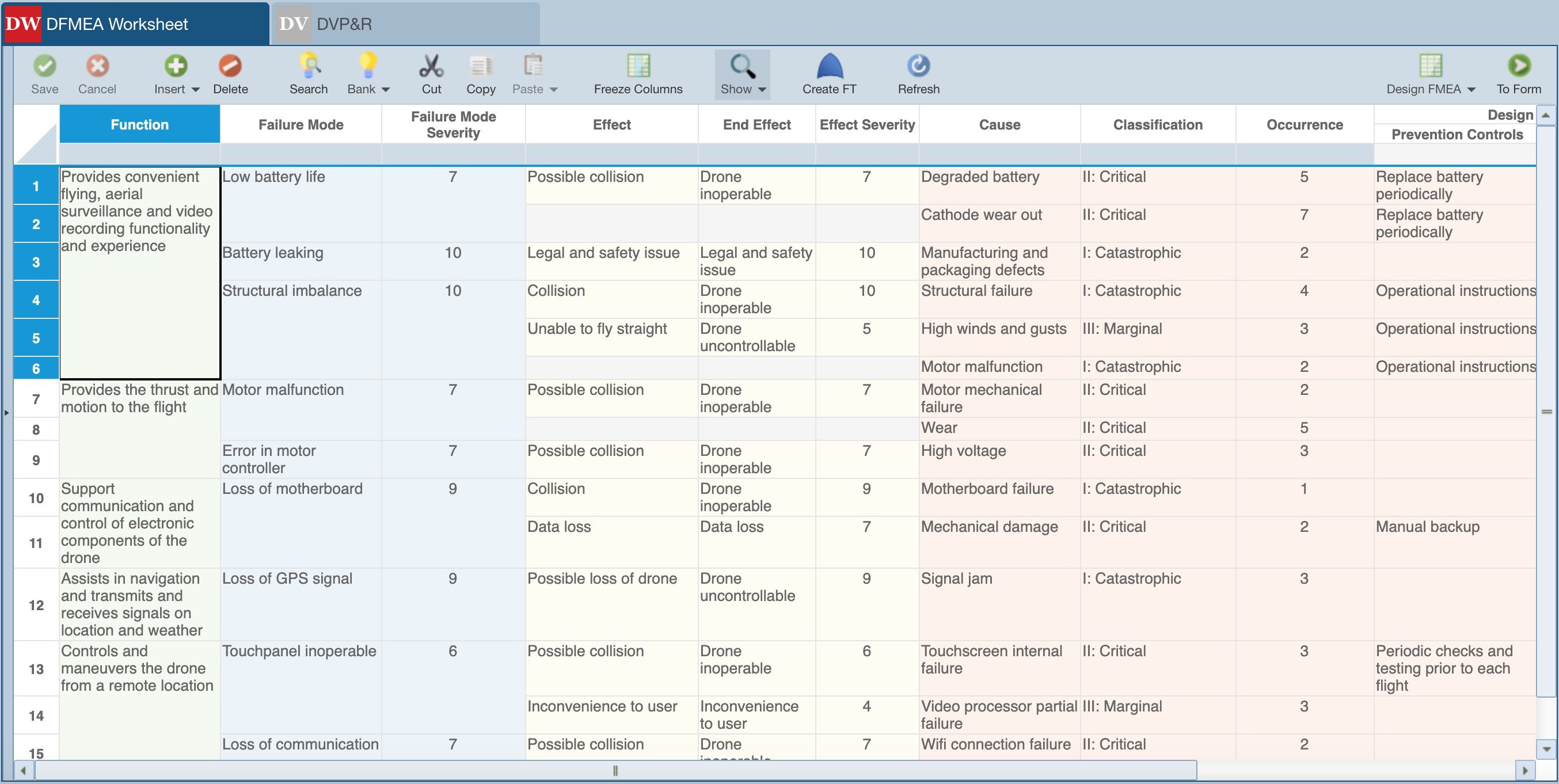

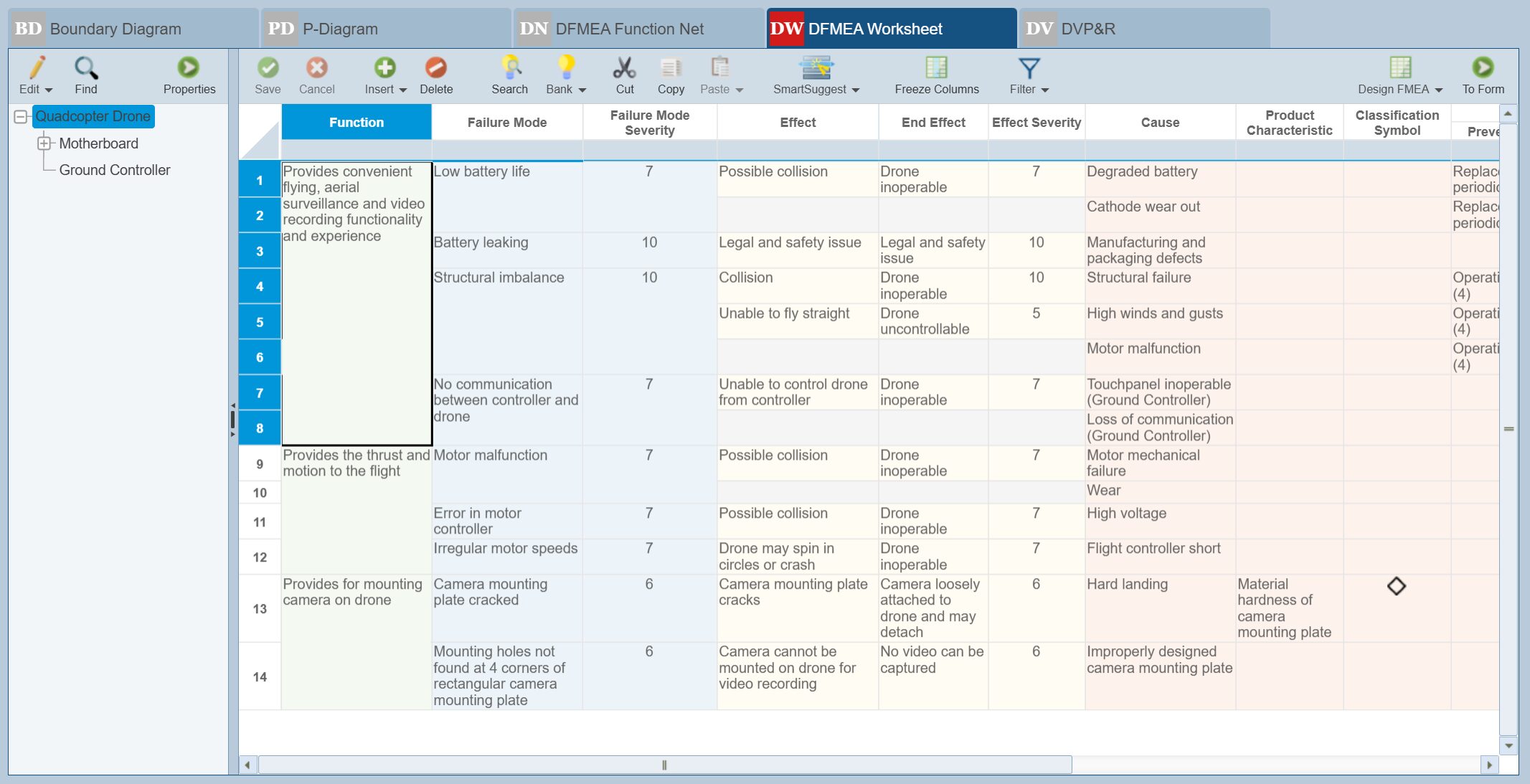

FMEA Worksheets

The central hub for FMEA activities resides in the FMEA Worksheet. Worksheets are tailored based on the type of FMEA being performed: DFMEA, PFMEA, FMECA, FMEA-MSR, or any custom FMEA. However, all FMEA Worksheets provide the same mechanisms for delineating all potential failure modes, prioritizing the risks associated with those failures, and then working through the tasks necessary to eliminate, mitigate, or detect those failures deemed most critical. The key part of all FMEAs is to ensure products and/or processes meet your risk and quality goals.

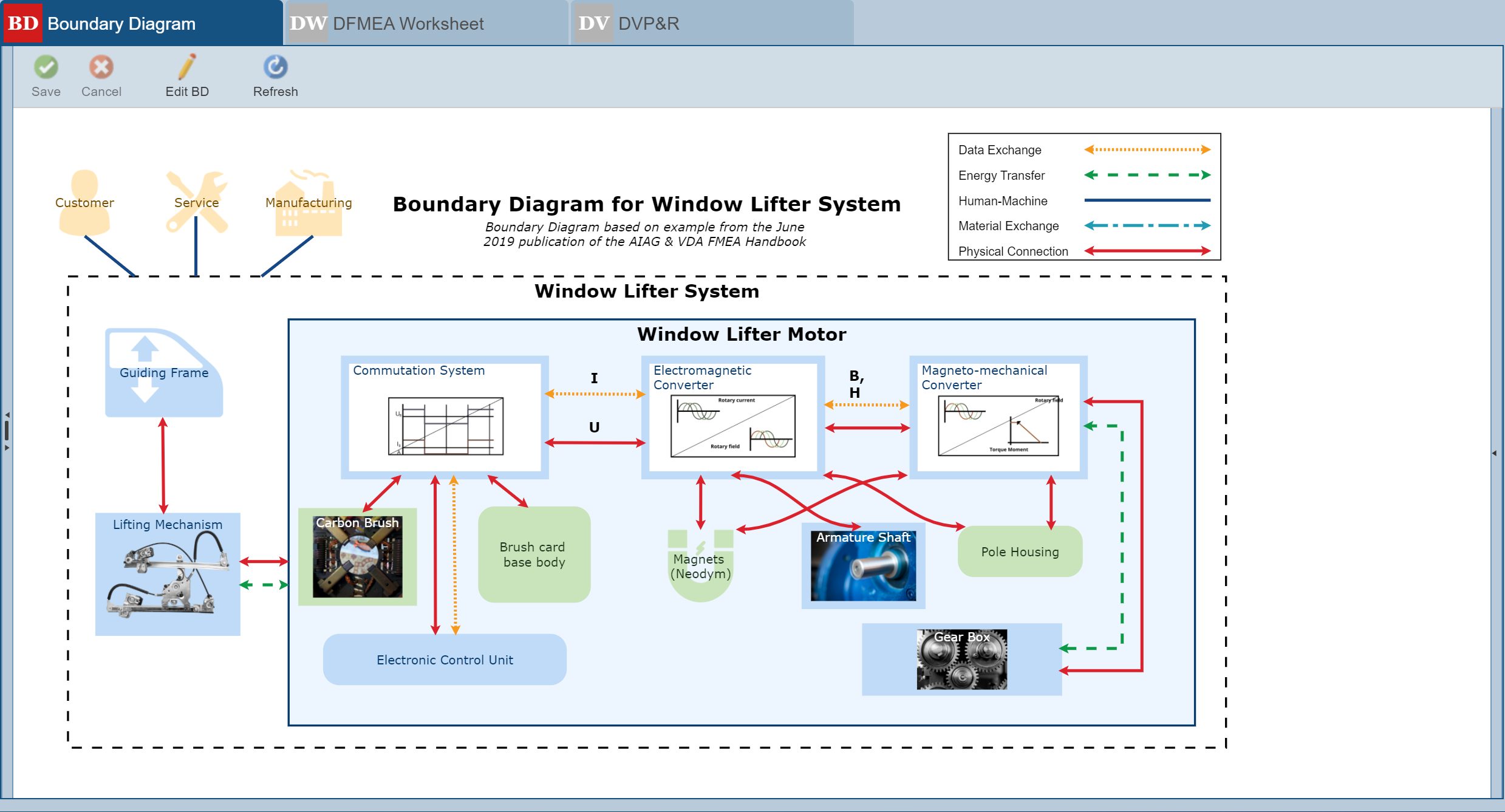

Boundary Diagrams

Boundary Diagrams in DFMEA are used to create a visual representation of the components of a system. The intent of a Boundary Diagram is to define the scope of analysis by providing a graphical diagram of a system’s interactions with internal and external elements. Boundary Diagrams use visual elements to represent the components of a system and the interfaces between components and external factors.

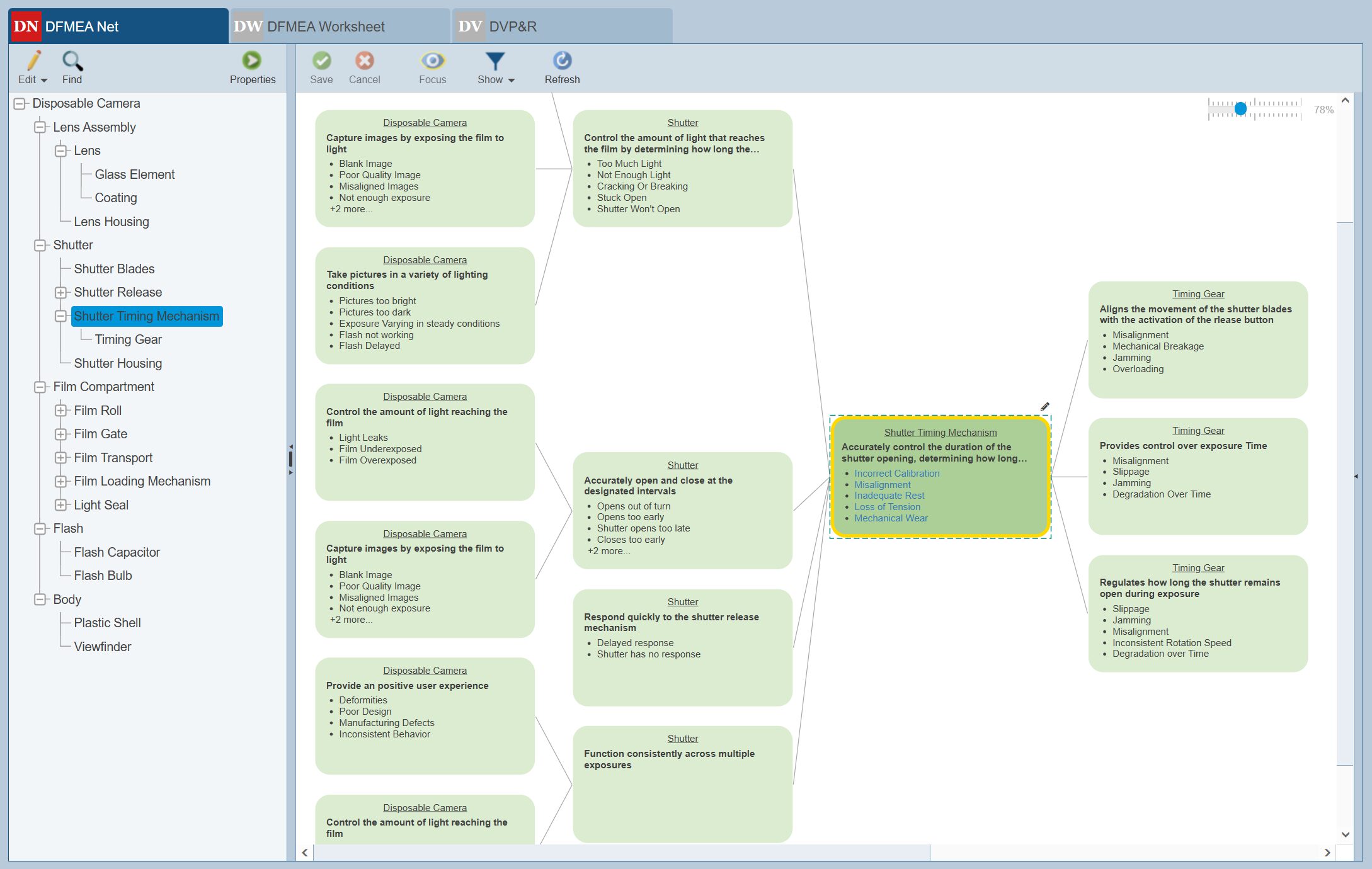

Function and Failure Nets

Function and Failure Nets in DFMEA offer a visual view of your system’s FMEA data and offer a valuable tool to improve the FMEA process, making it easier to pinpoint vulnerabilities and implement effective risk mitigation strategies. Function Nets allow you to explore the interplay between system Functions and can help to reveal design weaknesses. Failure Nets can be used to visualize how failures propagate through a system and provide a clear visualization of critical failure paths.

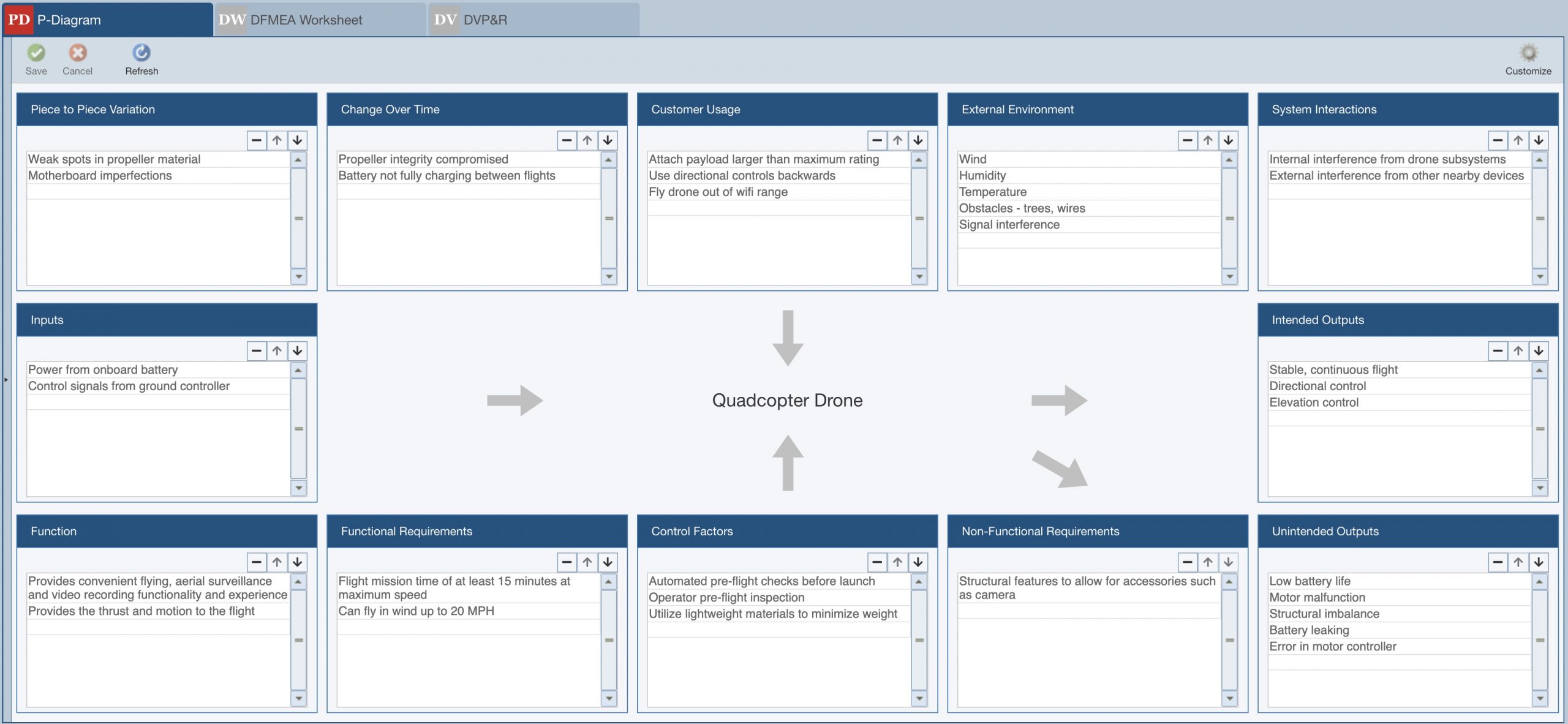

Parameter Diagrams (P-Diagrams)

P-Diagrams provide another layer to DFMEAs and PFMEAs that can be used for upfront assessment that your required design outputs are met considering all inputs. The central idea of P-Diagram analysis is to evaluate all the required outputs considering all possible inputs of a system prior to starting the FMEA Worksheet. Elements of P-Diagrams include input signals, output response, control factors, error states, and noise factors.

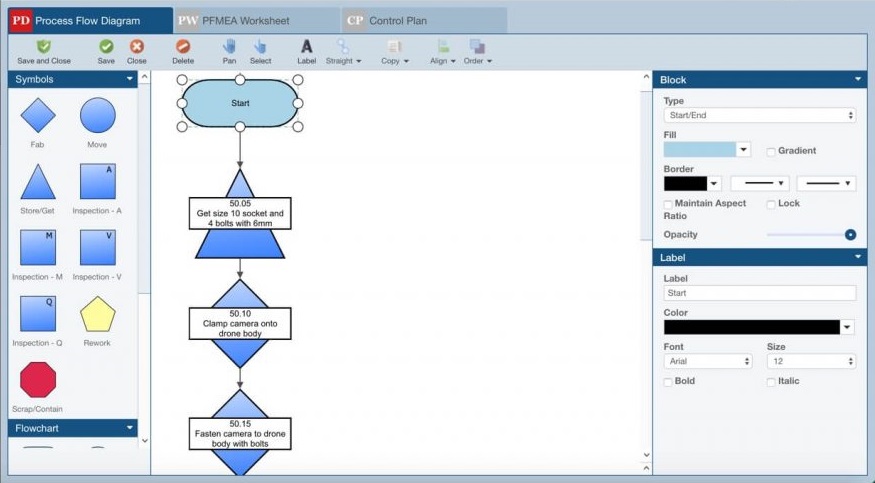

Process Flow Diagrams (PFD)

PFDs are a key component of a structured and well-planned Process FMEA. Relyence FMEA provides an easy-to-navigate interface for your PFDs, including both a fully functional graphical interface as well as a spreadsheet interface. You can choose to use either view or both views – switching between views with a simple click. Relyence FMEA’s unique always-in-sync™ technology ensures that your PFDs remain in sync with your PFMEA Worksheets and your Process Control Plans so that information across your entire PFMEA process remains intact and controlled.

Control Plans (CP)

CP, also referred to as a Process Control Plan (PCP), is an organized methodology ensuring that your quality standards and continual process improvement objectives are achieved. Relyence FMEA can be employed to effectively manage and organize your Control Plans. Or, Relyence FMEA can manage your entire PFMEA process by taking advantage of the unique always-in-sync™ technology to organize your control plans along with your PFDs and PFMEA Worksheets. Relyence FMEA maintains the data flow from one step of your PFMEA process to the next, keeping track of product and process characteristics, prevention and detection controls, and process steps.

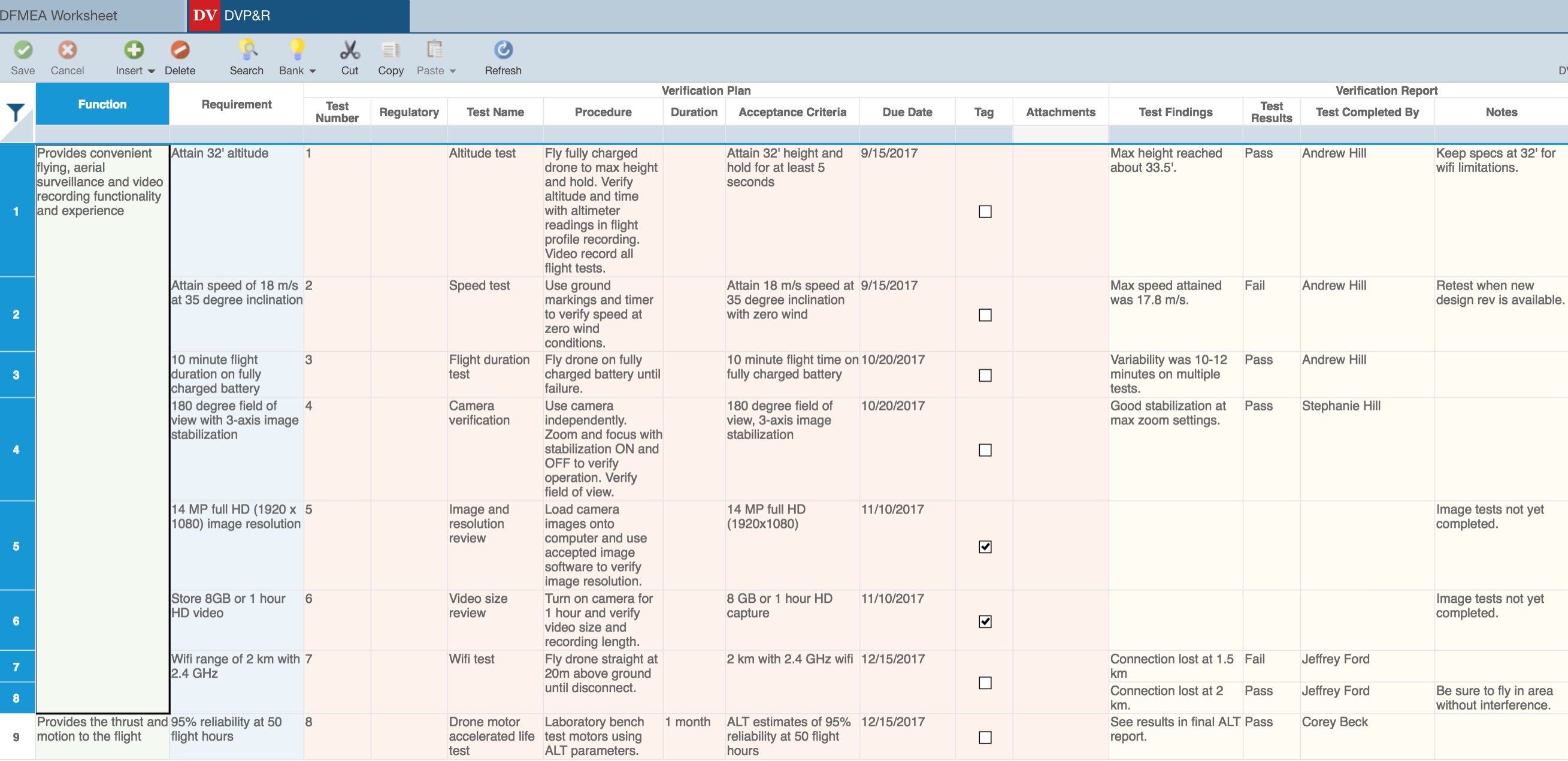

Design Verification Plan and Report (DVP&R)

DVP&R is typically used in conjunction with Design FMEAs. The objective of DVP&R is to manage and document your tasks associated with verifying that your product meets design requirements. The Plan part of DPV&R begins with listing your design specifications or product requirements along with the tests used to verify that the defined requirements have been met. The Report portion records the results of verification tests. You can track pass and fail testing, as well as keep track of progress and issues that may arise.

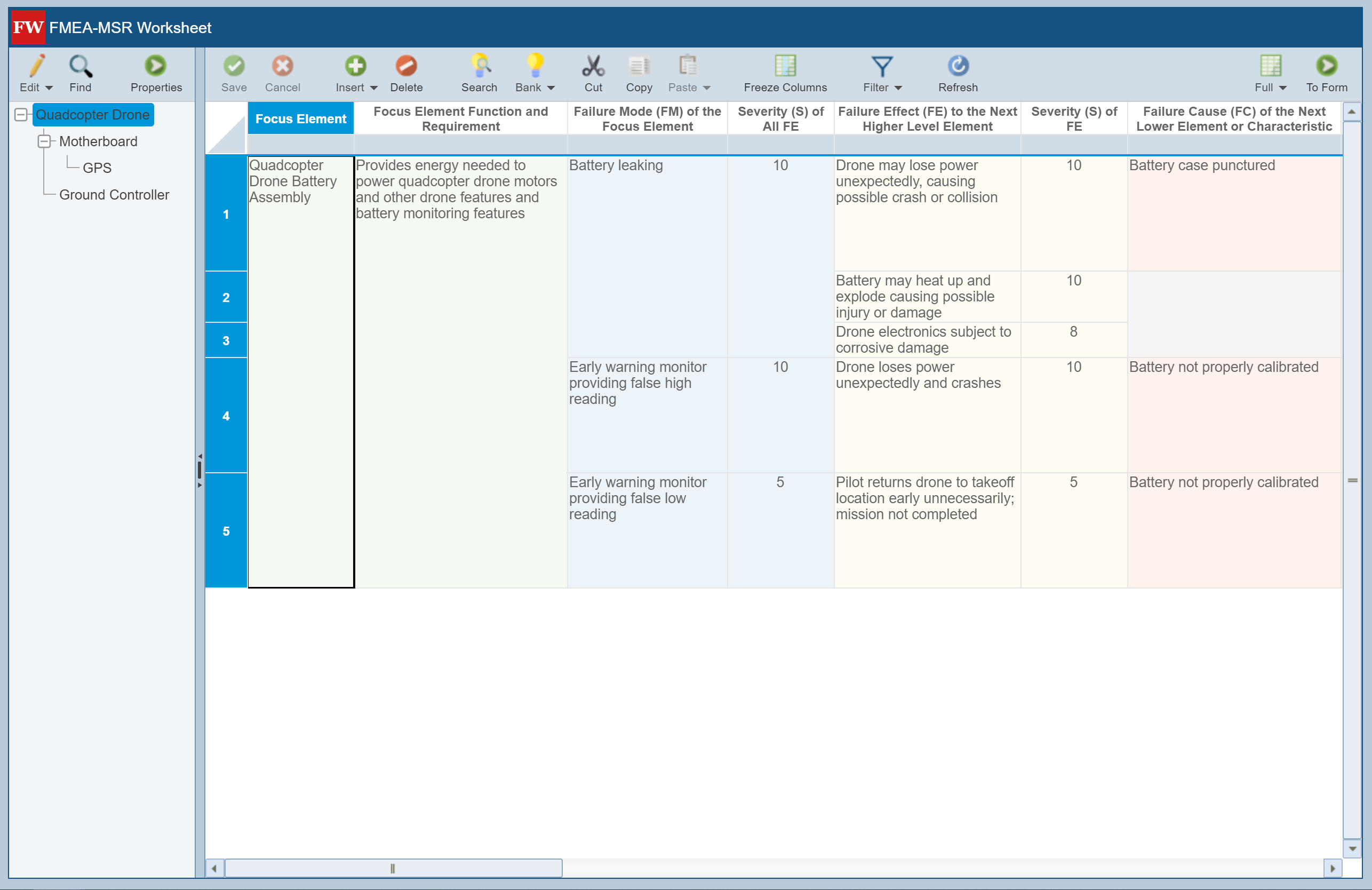

FMEA-MSRs for ISO 26262 Compliance

FMEA-MSRs, or Monitoring and System Response FMEAs, can be used to supplement DFMEAs. Introduced in the AIAG & VDA FMEA Handbook, FMEA-MSRs consider how a product will fail when in use by the customer. The intent of FMEA-MSRs is to keep products safe or ensure that they remain in compliance with regulations, such as with environmental statutes. FMEA-MSRs are designed to make sure safety goals required by ISO 26262 are met.

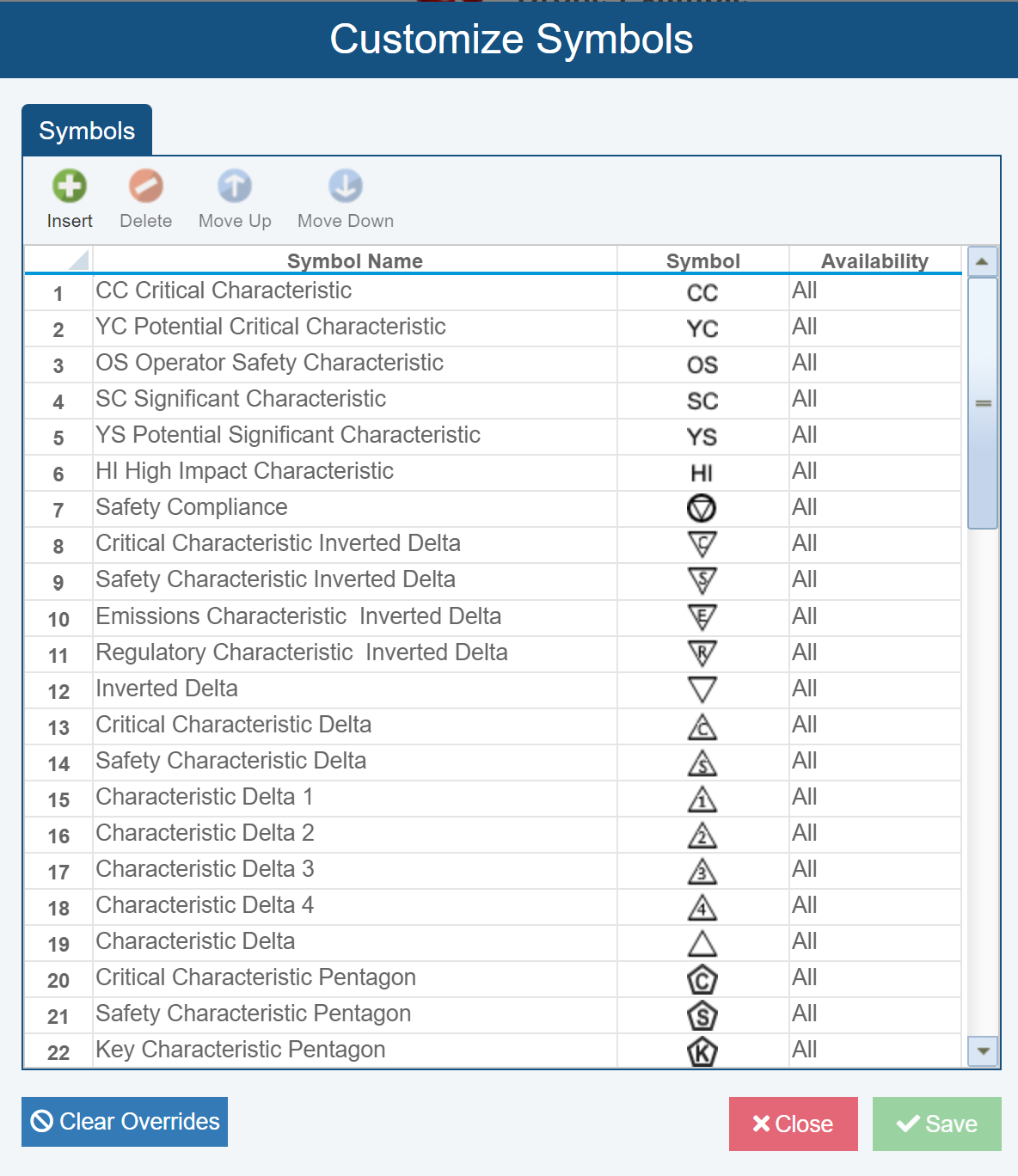

Classification Symbols

Relyence FMEA includes the ability to define Symbols for use across your DFMEAs, PFMEAs, and FMEA-MSRs. Symbols can be used for various purposes, including highlighting critical or key items, classifying various risk metrics, or any other purpose you may require.

Relyence FMEA comes with a built-in set of commonly used Symbols that can be used out-of-the-box or customized to your needs. Symbols can be applied to Product and Process Characteristics, assigned to certain Severity values, or chosen directly on your FMEA worksheets.

Customization: Adapting to Your Needs

Relyence FMEA offers complete control of all your FMEA data entry Worksheets. You can choose to start with one of our built-in templates based on a FMEA standard and modify it to suit your needs. Alternatively, you can create your own FMEA Worksheet using the data elements you desire. You can have multiple templates and can easily switch back and forth between them. You can share worksheets across teams, or even create individual custom worksheets. Customization extends across all FMEA entities: Design FMEA Worksheets, Process FMEA Worksheets, FMECA Worksheets, FMEA-MSR Worksheets, DVP&R Worksheets, Process Flow Tables, and Control Plans.

Benefits of FMEA Software Tools over FMEA Excel Templates

Excel templates and spreadsheets used to perform FMEAs are simply no match for the precision and automated power of Relyence software. Due to both the sheer amount of data and the collaborative nature involved in FMEAs, the manual processes required with Excel mean that your FMEAs are more error prone, less consistent, less organized, and much more difficult for your team to manage, maintain, and update. Relyence’s innovative and acclaimed Knowledge Bank™ offers an unparalleled way to create a master, best practices, or foundation FMEA to capture, store, and reuse your FMEA data. Capturing lessons learned in a searchable and encompassing databank means your FMEA knowledge is maintained and continually builds for maximizing your team’s potential. Relyence FMEA Data Autoflow™ provides an automated and customizable approach for handling FMEA data relationships. Autoflow Up and Autoflow Down enable you to control how FMEA data flows up and down your FMEA hierarchy for ultimate analysis efficiency. Relyence Failure Direct Connect™ integrates FMEA and FRACAS (Failure Reporting, Analysis, and Corrective Action System) for sharing failure information throughout the product lifecycle. Relyence FMEA always-in-sync™ technology offers a level of automation to your failure mode analyses that guarantees complete and controlled FMEAs. In addition, our intuitive interface, streamlined Worksheets, and a long list of powerful features combine to ensure your FMEA tasks are efficient as well as effective. The available Audit Trail feature provides the ability to capture, track, or review all FMEA modifications and edits, which is especially important in compliance-based efforts. For a complete listing of Relyence FMEA software advantages over Excel check out Move over Excel!