Jump to: How Exactly Do You Pronounce FMEA? | What are the Types of FMEA? | How Does a FMEA Process Work? The Steps to Perform a FMEA | What is a DFMEA or Design FMEA? | What is a PFMEA or Process FMEA? | What is a FMECA? | Other FMEA Types | Automating with FMEA Software

FMEA, or Failure Mode and Effects Analysis, is an organized, systematic approach for assessing potential system failures and the resulting consequences of those failures. The objective of a FMEA is to evaluate the risk associated with the identified failure effects and come up with a plan to detect, prevent, or mitigate those deemed most critical. Overall, FMEAs provide an invaluable approach for maintaining and improving your reliability and quality objectives. It is why FMEAs consistently remain one of the most used methodologies in corporate reliability and quality efforts.

In the post, we’ll help provide an overview of the different types of FMEAs and provide FMEA examples to help you understand the purpose and use of FMEAs.

First…How Exactly Do You Pronounce FMEA?

The term “FMEA” is sometimes pronounced simply by spelling out the letters of the acronym: “F”, “M”, “E”, “A”. Usually, it is pronounced as a word: “Fah-Me-Ah”. Sometimes “Fee-Mah” is heard, but this tends to be confusing because it more commonly applies to the Federal Emergency Management Association (FEMA).

Because there are various types of FMEAs, sometimes a qualifier prefix may be used. For example, Design FMEAs can be referred to as “D” FMEAs, and Process FMEAs as “P” FMEAs. In general, the term FMEA can apply to the broad scope of any type of FMEA analysis, but if you want to be specific, you can use the prefixes.

Additionally, the acronym FMECA stands for Failure Mode, Effects, and Criticality Analysis. In most cases this is pronounced as the three-syllable “Fah-Me-Kah”. You can also spell out all 5 letters, but that tends to get a bit long!

What are the Types of FMEA?

There are a variety of FMEA types; however, all are focused on the same function of risk assessment and the detection, elimination, and/or mitigation of critical risk events.

The primary types of FMEAs include:

- System / Functional FMEAs

- Design FMEAs

- Process FMEAs

- Service FMEAs

- Software FMEAs

- Manufacturing FMEAs

How Does a FMEA Process Work? The Steps to Perform a FMEA

The steps to complete a FMEA remain essentially the same across all FMEA types.

- First, you break down your system, design, or process into its component elements – as granular or as high-level as you prefer.

- From that point, you systematically go through each element and determine all the possible ways it can potentially fail.

- For each failure, you analyze the effects and the likely causes of that failure.

- You then proceed to rank each potential effect based on the risk criteria of your choosing. For example, you may consider such items as severity (how critical is it), its occurrence (how likely it is to occur), and detection (how likely it would detected). There are several standard methods to quantify risk level – such as RPN (Risk Priority Number) calculations that measure risk on a 1-1000 scale, and Criticality, which is a computed metric based on actual probability values. You can customize risk assessment criteria to best fit your needs.

- Once the potential risk levels are ranked, you delve in to the important part of the analysis – determining how to minimize, detect, eliminate, or mitigate those you deem most critical. Typically, analysts then define a plan of recommended actions to implement in order to keep failure effect risks low.

- You then go back and determine your revised risk levels based on completed action items to ensure you have met your risk goals.

As you can see from the description of the procedure, FMEAs are best performed collaboratively with a team of engineers and analysts across all elements of the product or process lifecycle – from design, to development, to production, and to deployment. FMEA documents are best utilized as living documents so that the product, process, or system is evaluated throughout the lifecycle to maintain and continuously improve reliability and quality.

For a walk-through FMEA example, see A Real World Example in Six Steps.

What is a DFMEA or Design FMEA?

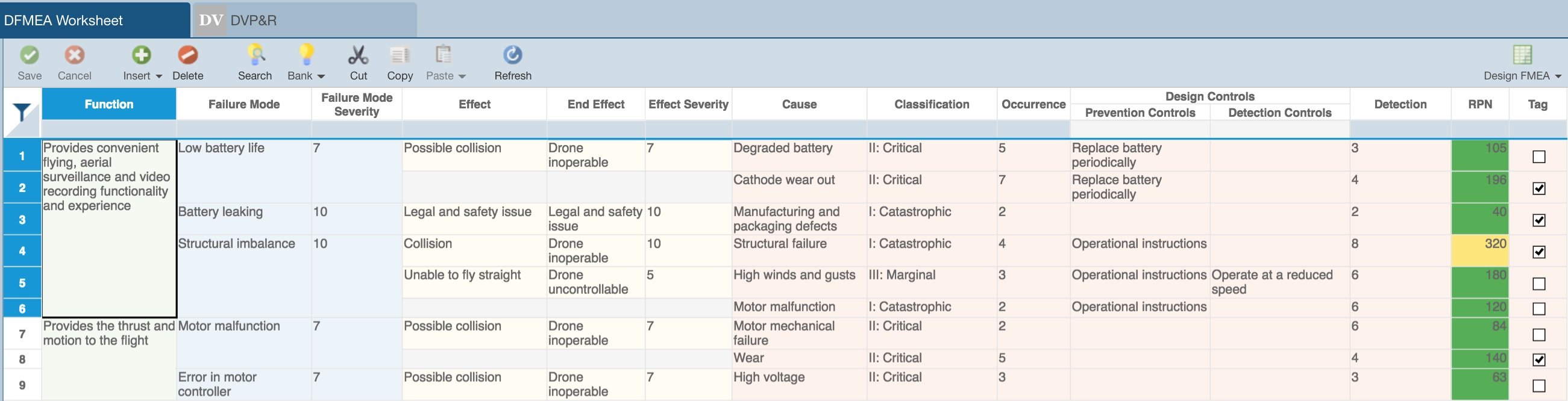

Design FMEAs, or DFMEAs, enable you to assess and address potential failure modes during the early or end stage of product design. When performing a Design FMEA, you begin by defining the system hierarchy, or the breakdown of all the individual components of your product. The breakdown can be as detailed as you like. For example, you may start your DFMEA early in the design phase when a high-level breakdown is available, and then as your design matures, continue to refine that breakdown into lower level elements.

Once your product design is broken down into components, you analyze the potential failure modes of each element. You then follow the remaining steps of the FMEA procedure as described earlier.

The steps of the DFMEA process include:

- Breakdown your system in a hierarchical format.

- Analyze the possible failure modes of each element in your system breakdown.

- Analyze the effects and causes of each failure.

- Rank the relative risk of each failure effect according to a criteria you prefer.

- Assign action items as needed to mitigate, eliminate, or detect high risk items.

- Go back and revise your risk levels based on completed actions.

- As your design matures, revisit your system breakdown to refine further and repeat steps 2 though 6.

Example DFMEA Worksheet

What is the purpose of a Design FMEA?

DFMEAs are use to analyze a product during the design stage. Their main purpose is to ascertain and mitigate critical effects of failures prior to manufacture and deployment.

Cost of Defect Correction Across the Product Lifecycle

In the product lifecycle, the cost of correcting a failure dramatically increases along every stage of a product’s life. Correcting a problem while in the design, or “paper” stage, is minimal – you reassess the design and make appropriate changes to the design documents. Your cost is limited to the engineering time for redesign. Moving onto production, if a problem is uncovered, the resulting costs go up tremendously. Production shutdown, re-engineering, retest, and restarting production are costly and ineffective. Lastly, failures uncovered in the field are the most costly. You may be facing recalls, product replacement, and repairs, as well as all the costs associated with determining the root cause and necessary corrective actions. Add to that the almost immeasurable cost of harm to your reputation and company standing, and you can see why eliminating problems early on is key to business success.

What is DVP&R?

DVP&R is an acronym for Design Verification Plan and Report. DVP&R analysis is sometimes used in conjunction with Design FMEAs.

The purpose of DVP&R is to manage and document your tasks associated with verifying that your product meets design requirements. Your design specifications or product requirements are listed in the DVP&R Worksheet along with the tests used to verify that your requirements and/or specifications have been met – the Plan portion of DVP&R. Once the tests are performed, the results are recorded – the Report portion of DVP&R. You can track pass and fail testing, as well as keep track of progress and issues that may arise.

DVP&R is a tool that ensures you have an organized approach to validation of product design, provides feedback to know how well your design is progressing in relation to verifying it meets requirements, and maintains all this information in a central place for efficiency and future design iterations.

Example DVP&R Worksheet

What is a PFMEA or Process FMEA?

Process FMEAs are used to analyze and maintain process control objectives. Essentially, PFMEAs are performed on a process as opposed to a product as with DFMEAs. The central component of a PFMEA is the PFMEA Worksheet, which can look very similar to a DFMEA Worksheet. In the initial columns of a PFMEA Worksheet you will break down the steps of your process instead of the components of your product as you would in a DFMEA.

You then follow the same FMEA procedure:

- Identify all potential failure modes of the process steps

- Determine the resulting effects

- Perform a risk assessment

- Define a plan for recommended actions for risk mitigation.

Oftentimes, PFMEAs are used in conjunction with Process Flow Diagrams (PFDs) and Process Control Plans (PCPs or CPs).

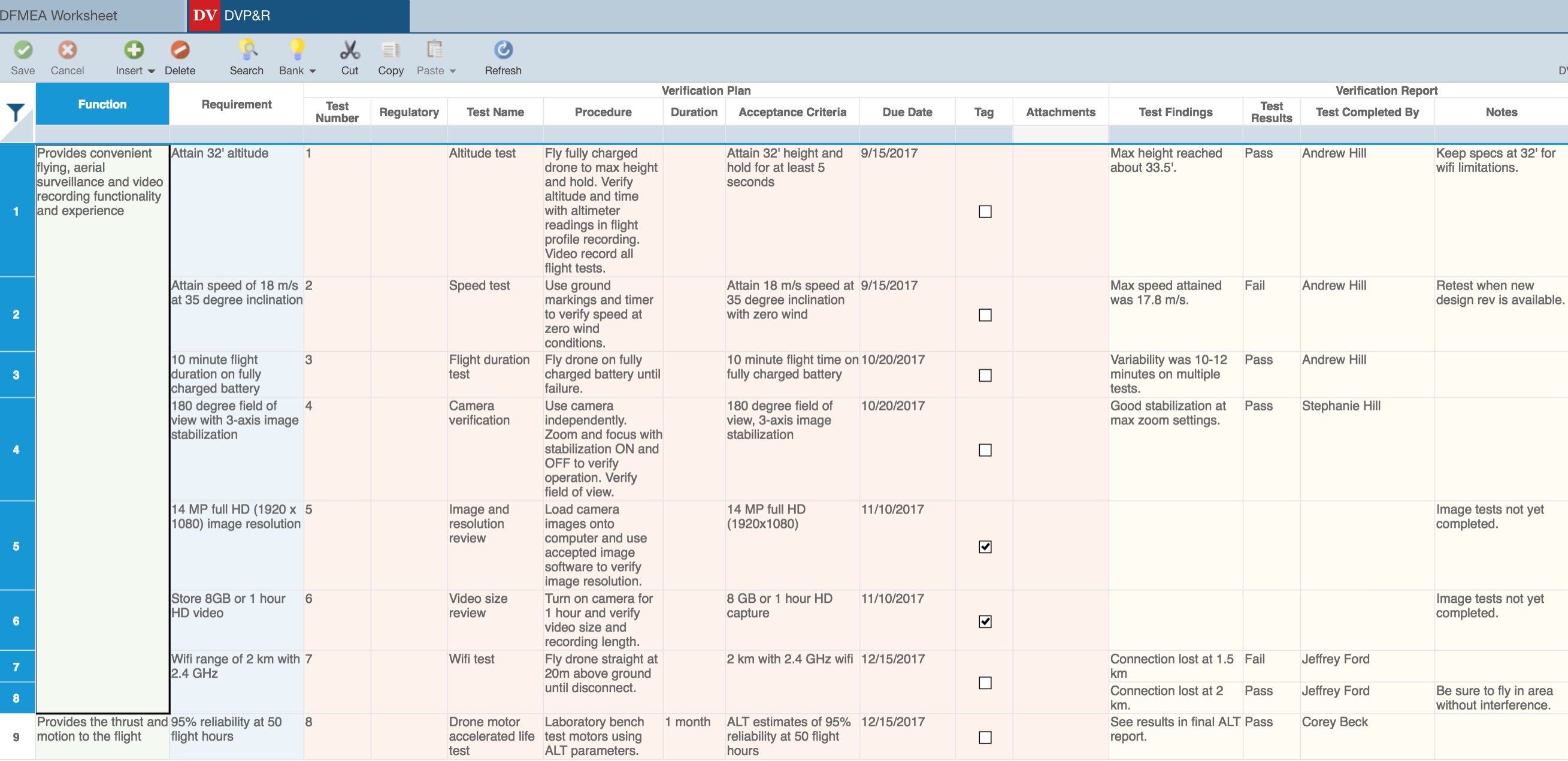

What is a Process Flow Diagram?

A Process Flow Diagram, or PFD, as indicated in the name, is a diagram, or visual view of a process. The PFD shows the flow of the process or equipment that is under analysis. Elements of a PFD resemble those of a flowchart, or flowsheet. This graphical view allows the overall process to be easily understood and grasped. Typically, there is a start node and an end node and then the interim blocks indicate the process steps to be analyzed.

PFDs include information based on your process requirements and specifications, such as product and process characteristics. This allows you to track and manage your requirements to ensure they are all met, and that all elements of your specifications are covered in your analysis.

Example Process Flow Diagram (PFD)

Once the PFD has been defined, the next step is to perform your PFMEA.

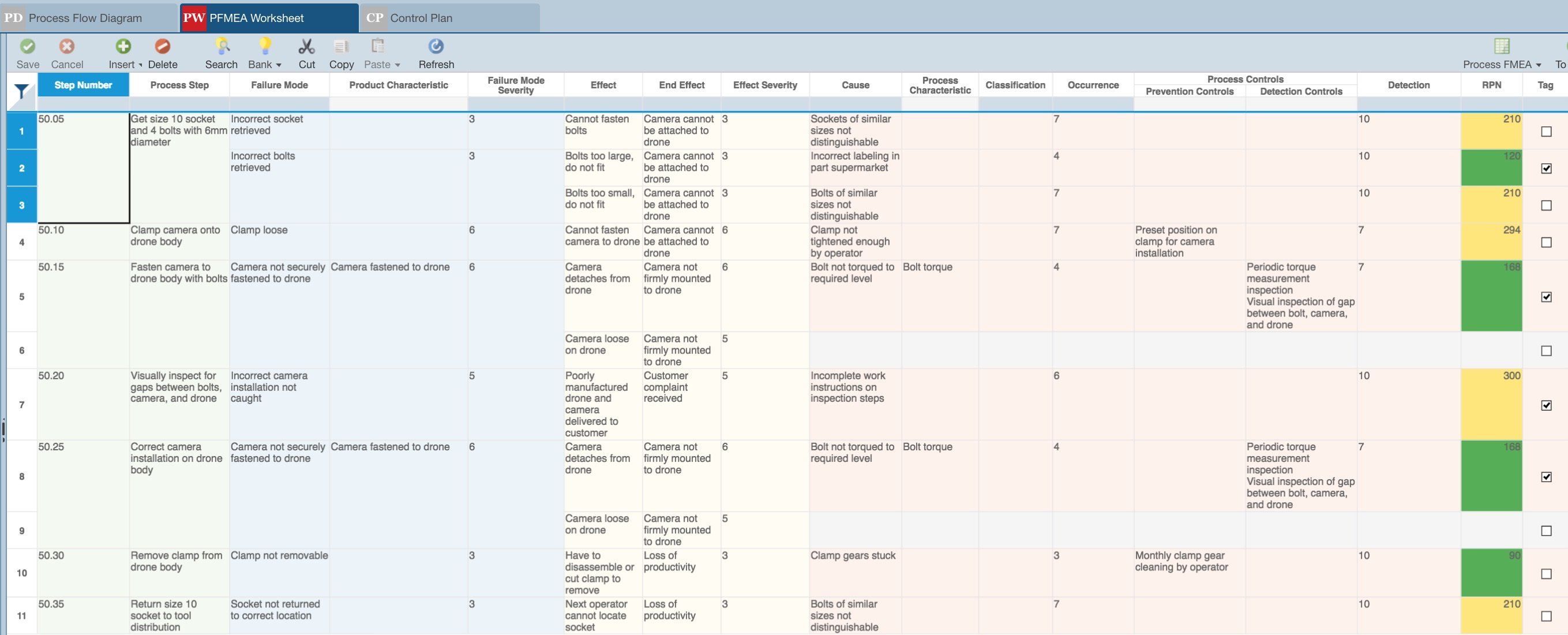

The Central Part of PFMEA: The PFMEA Worksheet

The PFMEA Worksheet shares the process steps delineated in the PFD. You consider each process step and determine the potential failure modes associated with each one. The remaining portions of the analysis are then completed: determine the effects of the failure modes, assess the risks of those effects, and then the actions required to eliminate or mitigate those effects.

Example PFMEA Worksheet

Once the PFMEA Worksheet is completed, or mostly completed, the next phase is to work on the Process Control Plan.

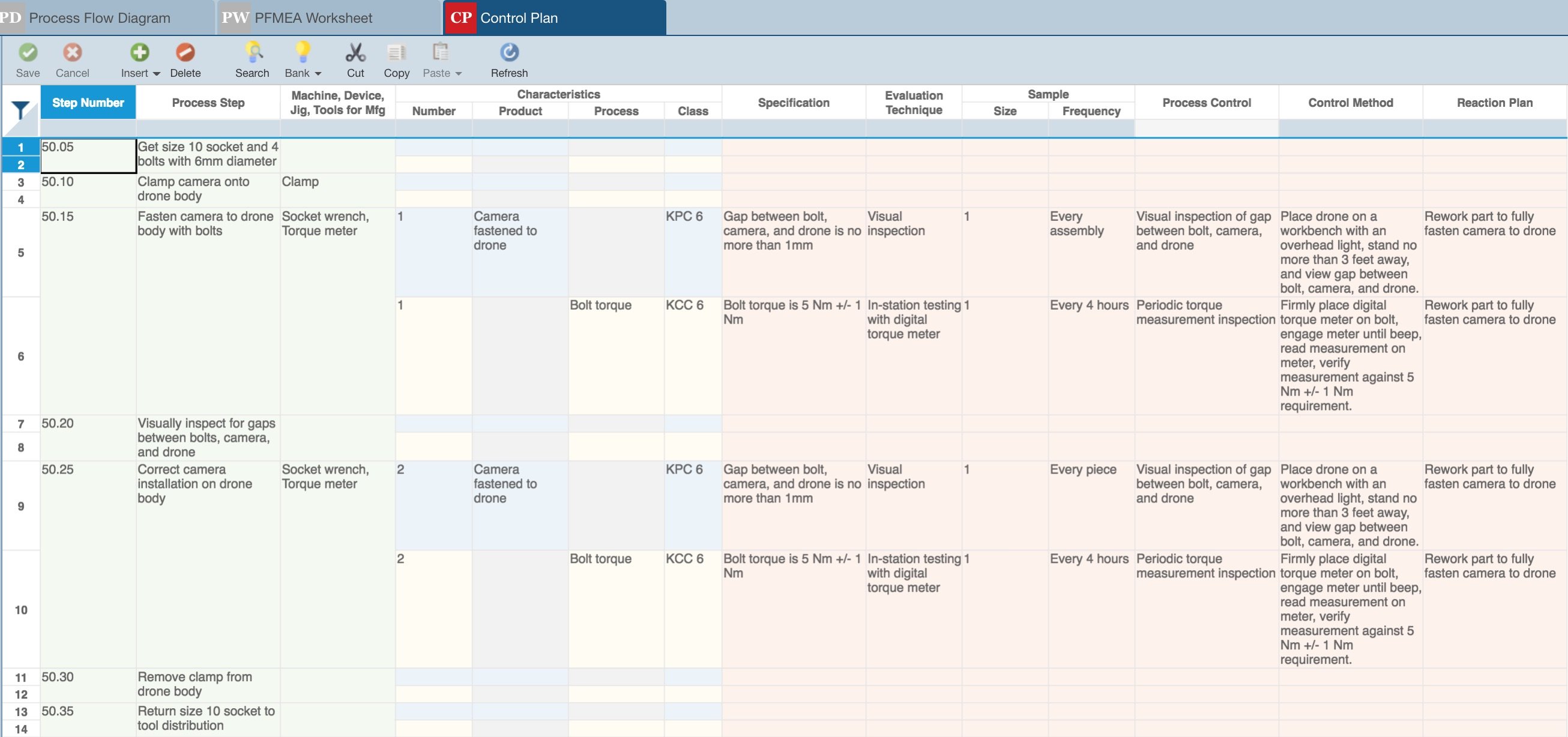

What are Control Plans Used For?

The Process Control Plan (PCP), or Control Plan (CP), details the methods you will use to control the product and process characteristics to ensure they meet your quality requirements. The CP is used as an organized, detailed plan for documenting all the controls put in place to address all the failure issues identified in your PFMEA. Ultimately, the CP can be used to create operator instructions.

Example Control Plan

As in your PFMEA Worksheet, the CP shares the process steps defined in your PFD. The process steps, product characteristics, and process characteristics are the linking mechanisms across all elements of the PFMEA process – from PFD, to PFMEA, to CP.

You do not have to use all elements – PFD, PFMEA Worksheet, and CP – you can use just one, two, or all three. Whichever you choose, the process steps are a critical element tying the components of your PFMEA together, so care should be taken when defining those steps. Almost all PFMEAs use the PFMEA Worksheet. Depending your needs, you may decide to include a PFD and CP as well.

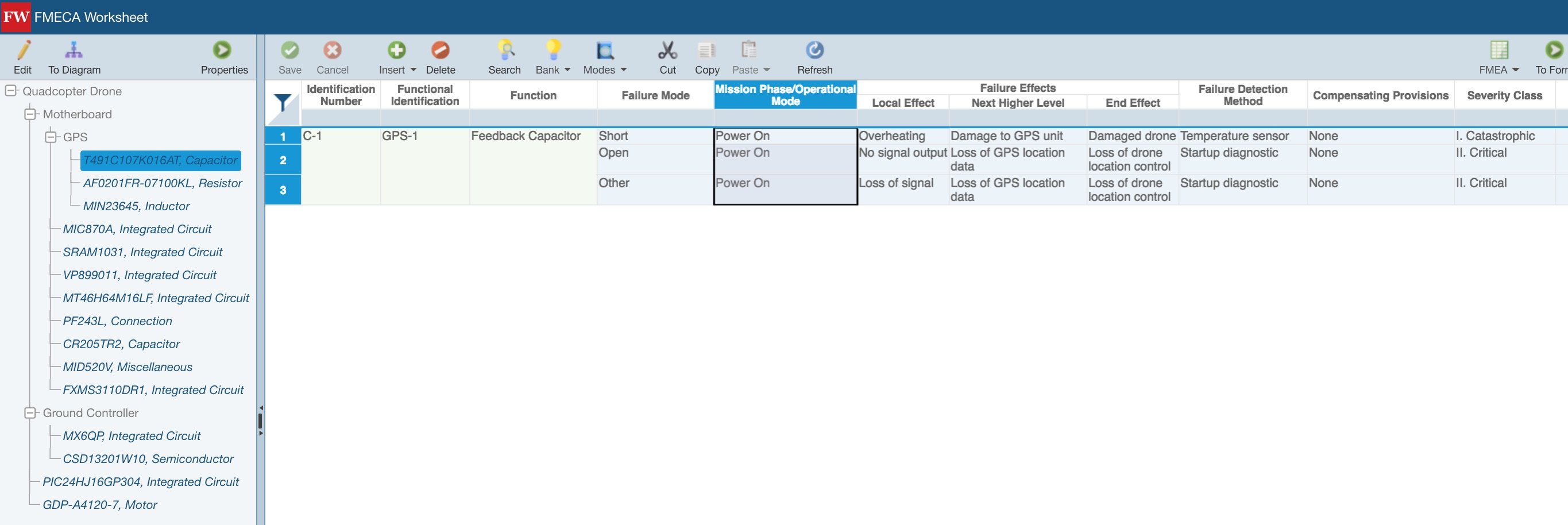

What is a FMECA?

FMECA, or Failure Mode, Effects, and Criticality Analysis, incorporates a specific type of criticality analysis in to the FMEA. Typically, FMECAs are performed based on the MIL-STD-1629A standard that defines a well-known and widely accepted procedure for FMEA. One of the defining characteristics of a FMECA (versus a FMEA) is the way criticality is assessed.

With MIL-STD-1629A FMECAs, you can use either a qualitative or quantitative approach to criticality assessment. With the qualitative method, the severity level of each potential failure effect is determined, along with the likelihood of occurrence of the failure mode. A criticality matrix, or graph, of severity versus occurrence is then used to evaluate risk level.

Using the qualitative method, first the Mode Criticality is computed as:

Item Unreliability x Mode Ratio x Probability of Loss x Operating Time

The Item Criticalities are then the sum of the Mode Criticalities. The resulting criticalities are then easily ranked based on their computed numeric value.

Another unique aspect often associated with FMECA is the level of system breakdown. FMECAs are often performed at the piece-part level. Piece-part FMECAs break down a system into component subassemblies, and then down to the device level. This means that each device in the system, down to each integrated circuit (IC), resistor, capacitor, etc., is outlined in the FMECA Worksheet. At the device level, you then consider each possible failure mode and its resulting effects on its parent component, and then ultimately on the system. Piece-part FMECAs are highly detailed, very organized, and exceptionally comprehensive.

Example piece-part FMECA

Other FMEA Types

There are various other types of FMEAs, all which follow that same basic FMEA procedure and are used to assess and mitigate risk. In addition, organizations frequently create their own custom FMEAs to best suit their unique requirements. Oftentimes, companies begin with a FMEA standard as a starting point and then adapt and customize it as needed. Some commonly used FMEA standards include SAE J1739, ARP5580, AIAG, and MIL-STD-1629A.

Some other FMEA types include:

- Functional FMEAs, sometimes referred to as System FMEAs, analyze the functions of a system. For example, before a design is finalized, you can use the functional requirements as a basis to perform a Functional FMEA.

- Software FMEAs are performed by analyzing the ways software can fail and what the resulting effects of those failures are on the system. As the breadth and depth of software dramatically increases in today’s systems, Software FMEAs can be vitally important to address all potential failure paths.

- Service FMEAs are unique in that they analyze a service you plan to provide or create in order to meet a customer’s needs.

- Manufacturing FMEAs are similar to process FMEAs in that they analyze the potential failures associated with a manufacturing process.

- FMEA-MSRs, or Monitoring and System Response FMEAs, were introduced in the AIAG & VDA FMEA Handbook, and consider how a product will fail when in use by the customer. The intent of FMEA-MSRs is to keep products safe or ensure that they remain in compliance with regulations.

Automating Failure Mode & Effects Analysis with FMEA Software

For overall efficiency, it is best to use a tool expressly built for performing FMEAs. You get the advantages of data sharing, reusability, built-in criticality and risk calculations, and support for team collaboration.

Because FMEAs are best performed as a team effort, selecting a FMEA tool that supports ease of collaboration, including web-friendly and mobile-friendly features, can be most effective.

Relyence FMEA was designed and built to meet all the needs of FMEA analysts. Supporting the most widely accepted standards with complete customization capabilities, along with powerful features for team collaboration, Relyence FMEA is the proven go-to tool for Failure Mode and Effects Analysis.

Feel free to contact us today to discuss your FMEA needs, or see Relyence FMEA in action today with a free trial!