With all the disruptions this year has brought to our lives, our work at Relyence has adapted to meet the ongoing challenges. We chose to delay our usual late spring/early summer release, and we regrouped, refocused, and went to work (from home!). We are committed to supporting our customers, to moving forward with our ever-growing user base, and to making continual improvements to our ever-advancing product line.

We are proud to introduce a hugely impressive Relyence 2020 Release 2. We’ve not only added a number of completely new innovations but have also added a long list of useful capabilities across our product line. Welcome to Relyence 2020 Release 2! The best just keeps getting better!

New! Introducing Failure Direct Connect

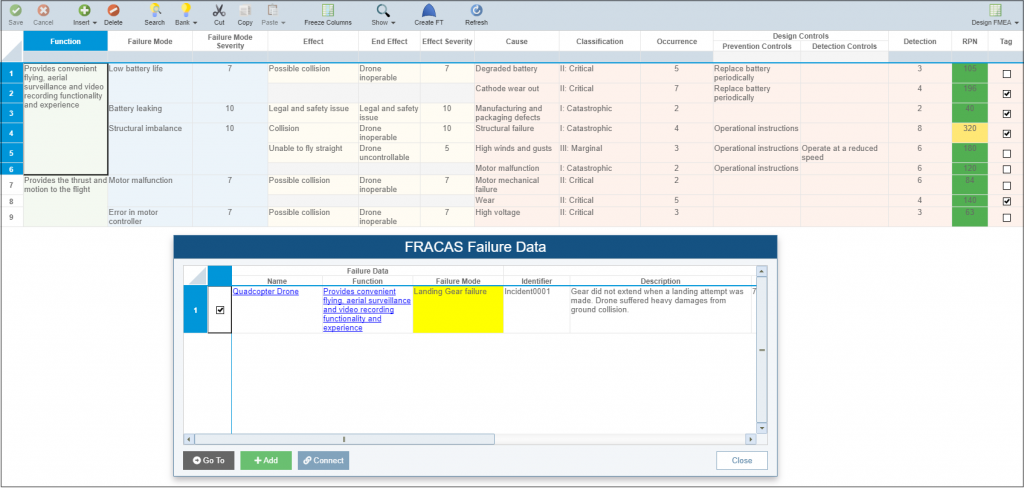

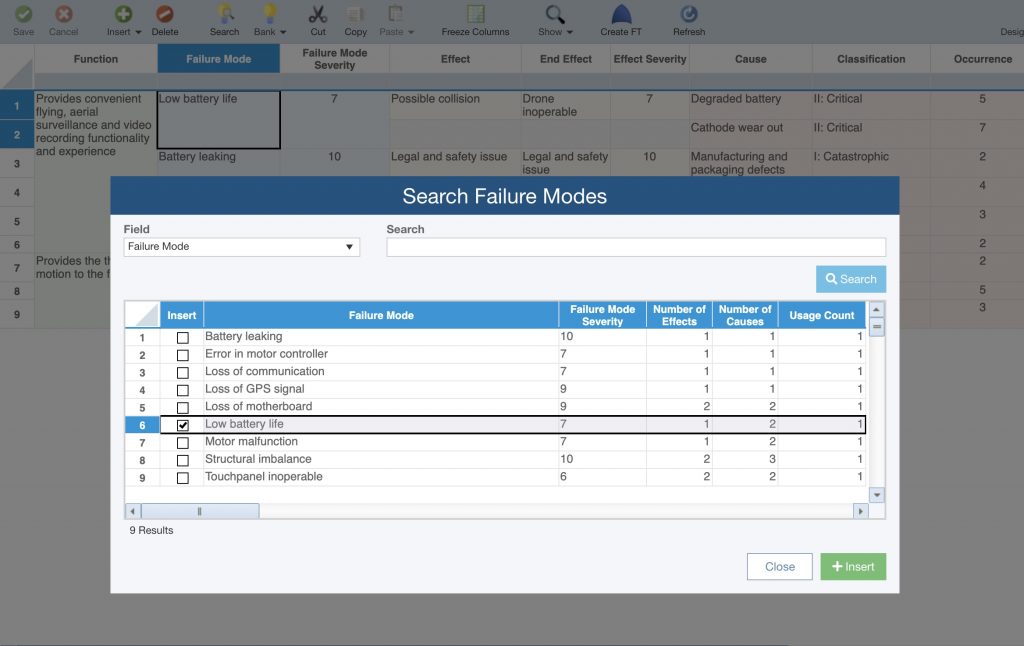

Long on our customers’ wish list is a way to integrate FMEA (Failure Mode and Effects Analysis) and FRACAS (Failure Reporting, Analysis, and Corrective Action System) for better management and control of failure analyses. The idea behind this capability is uniquely intriguing – but how exactly do you do it? It is a question that was never fully answered…until now!

Given our domain expertise, reliability knowledge, software design talents, and highly skilled development team, we recognized that we were perfectly suited to designing and delivering the solution. Relyence 2020 Release 2 introduces a completely new and innovative approach to fully control your failure information: Relyence Failure Direct ConnectTM.

Using Failure Direct Connect, your FMEA and FRACAS teams can work together to ensure that your failure analysis coverage is all-embracing and cohesive. The approach involves seamlessly integrating a multi-step process between Relyence FMEA and Relyence FRACAS.

Step 1: Perform FMEA

To begin, design engineers use FMEA to evaluate potential failures and the effects of those failures in a product design. By assessing the risk of the various identified failures, the design team works to ensure that actions are taken to eliminate, mitigate, or detect those failures in order to bring the design into accordance with risk profile goals.

Step 2: Deliver Product

Once the product design is finalized, product development, manufacture, and deployment take place.

Step 3: Track Issues with FRACAS

The product is delivered to the customer. At this point, organizations adopt some type of corrective action management system, such as FRACAS, to track and manage reported issues. Information such as the failure mode, the cause of failure, and other failure related information is recorded in the corrective action system.

Relyence Failure Direct Connect ensures your failure information remains connected throughout the product lifecycle.

At this stage, it is obvious that the information recorded during both the FMEA process and the FRACAS process directly overlap. This is where Relyence Failure Direct Connect steps in to provide an effective way to manage your failure information throughout the product lifecycle.

With Failure Direct Connect, the FRACAS analyst now has complete insight into the FMEA data. Instead of manually re-entering all the known information, the FRACAS failure data can be directly connected to the existing FMEA data.

But what happens if this is a newly uncovered failure mode that was not identified during the FMEA process? With Failure Direct Connect, the FRACAS analyst has the option to add in the new failure information and request that the FMEA be updated with the new findings.

FMEA analysts can then review the requests made by the FRACAS team and make decisions on how to proceed. Perhaps the FRACAS analyst misinterpreted the failure, and it needs to be connected to another element in the FMEA. Or perhaps, it is a newly discovered failure mode that needs to be addressed. Whatever the case may be, Relyence Failure Direct Connect handles all scenarios easily with a few mouse clicks!

Relyence Failure Direct Connect provides an innovative approach to integrating FRACAS and FMEA failure information.

With this innovative new ability to directly connect your FMEA and FRACAS processes, you can see how your overall quality management system becomes fully integrated for utmost effectiveness. Your design engineers and field personnel are now communicating directly. You are not only ensuring all failures are identified, but also that they are properly addressed.

By using Relyence Failure Direct Connect, you can be confident that lessons learned are not lost. Failure Direct Connect provides yet another Relyence-only powerful capability for more expansive and thorough failure control, tracking, and management.

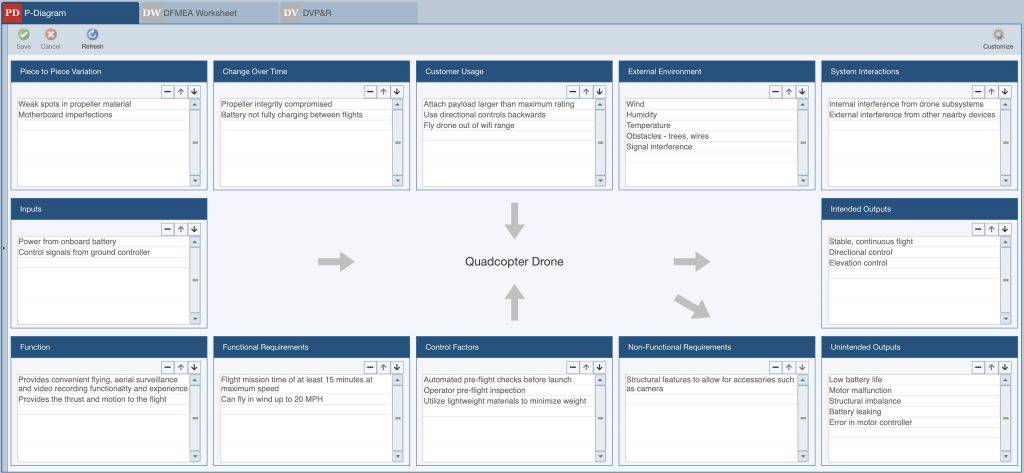

New! P-Diagrams in FMEA

P-Diagrams (Parameter Diagrams) provide another layer to FMEAs that can be used for upfront assessment that your required design outputs are met considering all inputs. P-Diagrams are an optional element that is typically used as the first step in the DFMEA or PFMEA process.

The central idea of P-Diagram analysis is to evaluate all the required outputs considering all possible inputs of a system prior to starting the FMEA Worksheet. P-Diagrams provide a way to review all the inputs that should be considered in order to achieve the required outputs. They can be especially helpful when designing complex systems that have many interactions and specific design requirements. Because P-Diagrams provide a compact visual overview, they can aid in understanding the overall system and the interactions of various factors influencing successful operation. Oftentimes, information from the P-Diagram analysis is used as a starting point for the FMEA Worksheet.

In P-Diagrams, there is a set of certain aspects to consider during system design – these include:

- Input Signals: The items required for meeting the basic system functions.

- Output Response: The desired outputs of the system.

- Control Factors: The factors the designers can use in order to meet design requirements.

- Error States: A list of undesirable system outputs that could occur.

- Noise Factors: These are the items that a design engineer may not be able to control but that have an influence on the system. Some examples of common Noise Factors are piece-to-piece variation, unintended customer usage, changes over time, external environment, and other system interactions. While they may not be controllable by the designer, the product should nevertheless be capable of handling the Noise Factors.

P-Diagrams, or Parameter Diagrams, provide a concise visual overview for design analysis.

All the elements of a P-Diagram are then placed in a series of text boxes that delineate all the identified items in each category. The end result is a concise, easy-to-read overview of all items that should be analyzed and evaluated by the engineering team. P-Diagrams offer a great way for the design and development team to think about the design at a high level, brainstorm, and develop a good understanding of the system before the structured design process begins.

In Relyence FMEA, you can now optionally enable P-Diagrams. You can also fully customize the P-Diagram as you require by choosing the elements that make up your diagram and naming them to your specifications. Additionally, the data from your P-Diagram can be added to your FMEA Worksheets using the Insert P-Diagram Data feature.

New! Fault Tree and Event Libraries

Fault Tree Analysis (FTA) is a fundamental and widely used technique for risk assessment. FTA employs a top-down deductive approach to analyze high risk and safety issues in critical systems. Using Boolean logic, a fault tree diagram is constructed to evaluate all the possible conditions that may lead to the top-level undesirable event.

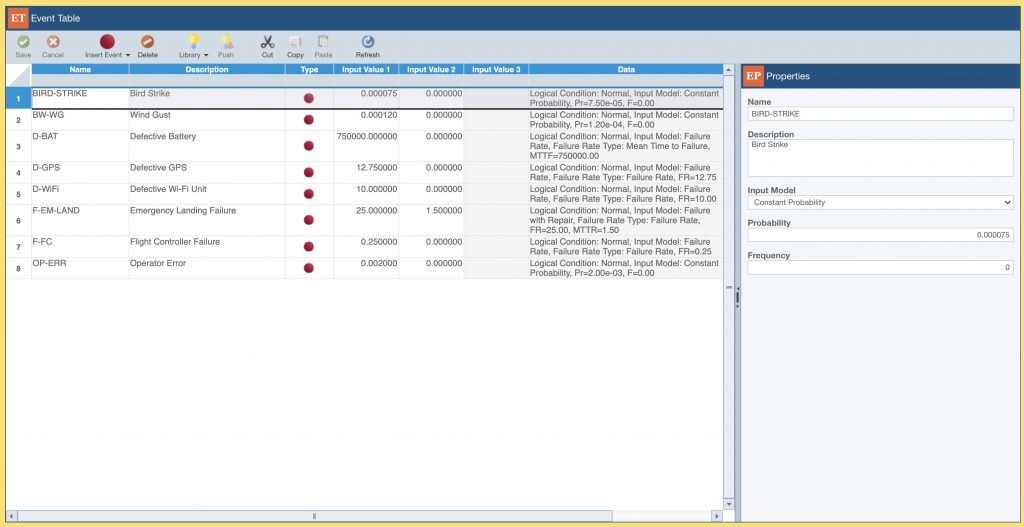

Depending on the system, fault tree diagrams can become very large and complex – this makes managing them critical for effective and accurate analysis. Relyence 2020 Release 2 introduces Fault Tree Libraries and Event Libraries to enable to you to more efficiently control and manage both entire diagrams and underlying event data.

Relyence Fault Tree Libraries allow you to save diagrams and all encapsulated data for reusability, management, and archiving. For example, you may have subtrees or portions of a fault tree diagram that are used across multiple FTAs. Or, you want to store a particular subtree with the knowledge that it may be required again in future analyses. With a click of a button, you can save your fault tree diagrams to a Fault Tree Library. This databank of vital fault tree data is then available for you to retrieve and reuse as needed.

When constructing fault trees, the lowest level is represented by events. Events allow you to model any type of failure such as hardware failures, human errors, system faults, or any failure event you choose. Types of events that can be modeled in Relyence Fault Tree include Basic, House, Undeveloped, and Repeated. The behavior of events is described by using mathematical models and related parameters. Relyence Event Libraries enable you to store a collection of described events for later reuse. Not only does this make fault tree construction more efficient, it also ensures data consistency.

The Fault Tree Event Libraries, along with the Fault Tree Libraries, provide an effective way to manage your FTAs.

Relyence Fault Tree Libraries and Event Libraries are independently managed, so you can use them individually or in conjunction with one another. These impressive new additions to Relyence Fault Tree allow you streamline your FTAs for fast, accurate analyses.

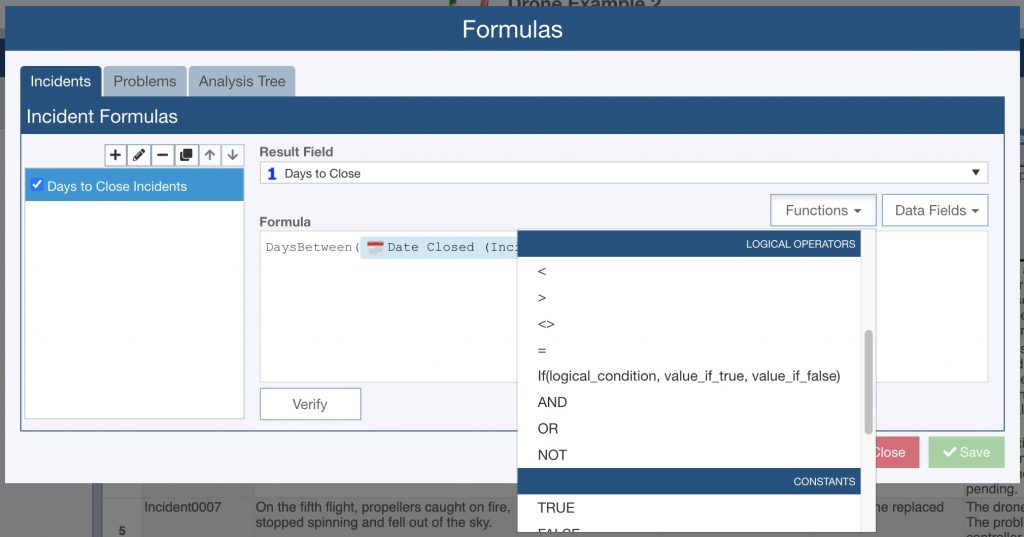

New! Formulas

Relyence 2020 Release 2 introduces a powerful new capability: Formulas. Much like Formulas in Excel, Relyence Formulas provide an extremely flexible way for you to define formula-based equations in your FMEA, FRACAS, and Reliability Prediction analyses.

The Formula Builder allows you to define any number of Formulas to evaluate during the calculation process.

Formulas support an array of capabilities, including:

- Arithmetic operators such as +, -, * and /

- Programmatic functions such as if/then/else

- Date Functions such as Date, CurrentDate, DaysBetween, and AddDays

- Constants such as TRUE and FALSE

- Logical operators such as AND, OR, NOT, <, >, <>, =

- Math functions such as ABS, CEILING, FLOOR, POW, SQUARE, SQRT

- Rollup functions such as Sum, Avg, Max, and Min

- Aggregate functions such as Sum, Avg, Max, Min, and Count

The Formula Builder enables you to create your own customized calculations.

The Formula Builder enables you to create your own customized calculations.

Formulas can operate on any available data fields on your Tables and Forms. The Formula Builder also includes a Verify button to enable you to verify that your defined Formula is valid.

For example, you could define a FMECA Formula such as:

If Detectable = TRUE then Detected Failure Rate = Failure Mode Rate and Undetected Failure Rate = 0.

You can then also define a Formula to sum all Detected Failure Rate and Undetected Failure Rates.

Even from this small example, you can envision the power available with Formulas!

New in Reliability Prediction

Additional Part Models

Relyence 2020 Release 2 now includes two new part models for Reliability Prediction, the Arrhenius model and the Test Data Extrapolation model. Both of these models can be found under the Miscellaneous Category.

The failure rate for the Arrhenius model is computed by the equation:

Failure Rate = A * e(-E/(K*T))

Where:

A = K factor, a user-entered pre-exponential non-thermal constant

E = Activation energy in eV, a user-entered value

K = Boltzmann’s constant

T = Temperature, based on entered temperature

The failure rate for the Test Data Extrapolation model is computed by the equation:

Failure Rate = Chi2(a,b) / (2 * Number of Test Devices * Number of Test Hours * AF)

Where

Chi2 (a,b) = Inverse Chi-squared value where p-value = a and b degrees of freedom

a for Upper Bound = (Confidence Level / 100)

for Lower Bound = 1 – (Confidence Level / 100)

b = 2 * (Number of Failures + 1)

AF = Acceleration Factor:

AF = e (E/K) * (( 1/Operating Temperature) – (1/Burn-in Temperature))

Where

E = Activation energy in eV, a user-entered value

K = Boltzmann’s constant

Note: When used in the above equations, Temperatures are in Kelvin. All temperatures in Relyence are entered in Celsius, and Relyence converts temperature values to Kelvin for you.

Failure Rate Adjustment

Also, Relyence Reliability Prediction now offers the ability to adjust failure rates computed based on a known environment and temperature to a different environment and temperature. The adjustment is based on a table of conversion factors defined in the Rome Laboratory Reliability Engineer’s Toolkit publication.

For example, you may know the failure rate of a component when in use in a Ground Fixed environment at 30° C. However, your current operating conditions are Ground Mobile at 35° C. Using the new Adjust Failure Rate capability, you can specify the failure rate and the reference environment and temperature and Relyence will automatically adjust it to the operating conditions.

New in FMEA

Knowledge Bank Push Management

Relyence’s innovative Knowledge BankTM has rapidly become a must-have feature for Failure Mode and Effects Analysis. Knowledge Banks provide a powerful way to automate FMEAs, reuse knowledge, and capture lessons learned. The Push mechanism built into the Relyence Knowledge Bank function provides the ability to ensure all FMEAs remain up to date with the latest information.

The Knowledge Bank, a Relyence innovation, has rapidly become a must-have feature for FMEA.

Now in Relyence 2020 Release 2, the ability to control and manage the Knowledge Bank Push operation is taken to a new level. Using the Push feature, you can now view all the pending changes and optionally select which changes are made. The Push Change Viewer provides a detailed listing of all changes that are pending for your FMEA data tied to Knowledge Banks. This data can be viewed either by Analysis or by Change depending on the situation.

You can then select individual changes to push out and those which can be held off to a later time. For example, perhaps you know that a particular Analysis is under a review process currently and you want to hold off any changes until that review is finalized. In Relyence, you can designate that push changes do not occur to that Analysis but to all others.

The new Push control feature is just one of the ways we continue to improve and advance this already impressive Relyence-only capability.

Auto-activate Workflow on new Subsystems

If you utilize another Relyence-only innovation – FMEA Workflow – you can now ensure that new FMEAs employ the process automatically. By enabling the Activate FMEA Workflow for all new Subsystems option, any time a new FMEA is started, your defined Workflow process is automatically activated.

New in FRACAS

Customized Terminology

By default, Relyence FRACAS uses the term Incident for a single reported item, and Problem for an item elevated to a full corrective action close-out process. You now can customize these terms and your preferred nomenclature will be used throughout Relyence FRACAS. A commonly used example is Defect for Incident and Nonconformance for Problem.

Fully indentured Analysis Tree

Using Relyence FRACAS Associations enables you to link across Incidents, Problems, and Analysis Tree items in a variety of ways. Now, when linking FRACAS elements to Analysis Tree items, the full system indenture can optionally appear when making your selection. This visual indication makes it easier to find the precise location for your linkages.

New in Fault Tree

Importing and Exporting

With Relyence 2020 Release 2, Relyence Fault Tree now supports complete importing and exporting of your fault tree diagrams. The streamlined, easy-to-use Import Wizard is employed to walk you step-by-step through the import process. To import or export your fault tree data, simply select Import or Export from the Sidebar when Relyence Fault Tree is active.

New Reporting Options

When generating a Fault Tree report, you now have three available options:

- Current Fault Tree

- Current Fault Tree and Subtrees

- All Fault Trees and Subtrees

More New Capabilities

Along with all these exciting new features, there is a lengthy list of additional capabilities included in Relyence 2020 Release 2:

- Audit Trail tracking and reporting extends to Users and Groups changes

- RBD reports can selectively include the current RBD, the current RBD and all Subdiagrams, or all RBDs and Subdiagrams

- A new hyperlink data field is available for inclusion on Tables and Forms

- A new image data field is available for inclusion on Tables and Forms and can include multiple images

- Importing now supports updating data

- Workflow responsibility can automatically be set to the current user in FMEA and FRACAS

- Titles of columns in Tables and Reports can be rotated vertically for a more condensed view

- And more!

Free Trial of Relyence Reliability Software

If you are a current Relyence cloud-based customer, you will see all the new capabilities now! If you are an on-premise customer, you will be able to access all these new features once you update your installation.

Once again, we’d like to offer a huge “Thank You!” to all our customers for helping us to improve our products by continually providing us with new and valuable ideas and suggestions. If you are current Relyence customer, a soon-to-be customer, or are a future customer, please feel free to reach out with your comments. You all help us to remain the best in our field!

As always, if you would like to check out these new features, or any of the capabilities of the Relyence software tool suite, you can sign up for completely free trial. No hassle, no strings, just register here and put us to the test! Or call today to speak to us about your requirements or schedule a personal demo at your convenience.