Relyence RCM Software Overview

Perform Reliability Centered Maintenance analysis in a flexible, friendly software tool

Compliant RCM Analysis

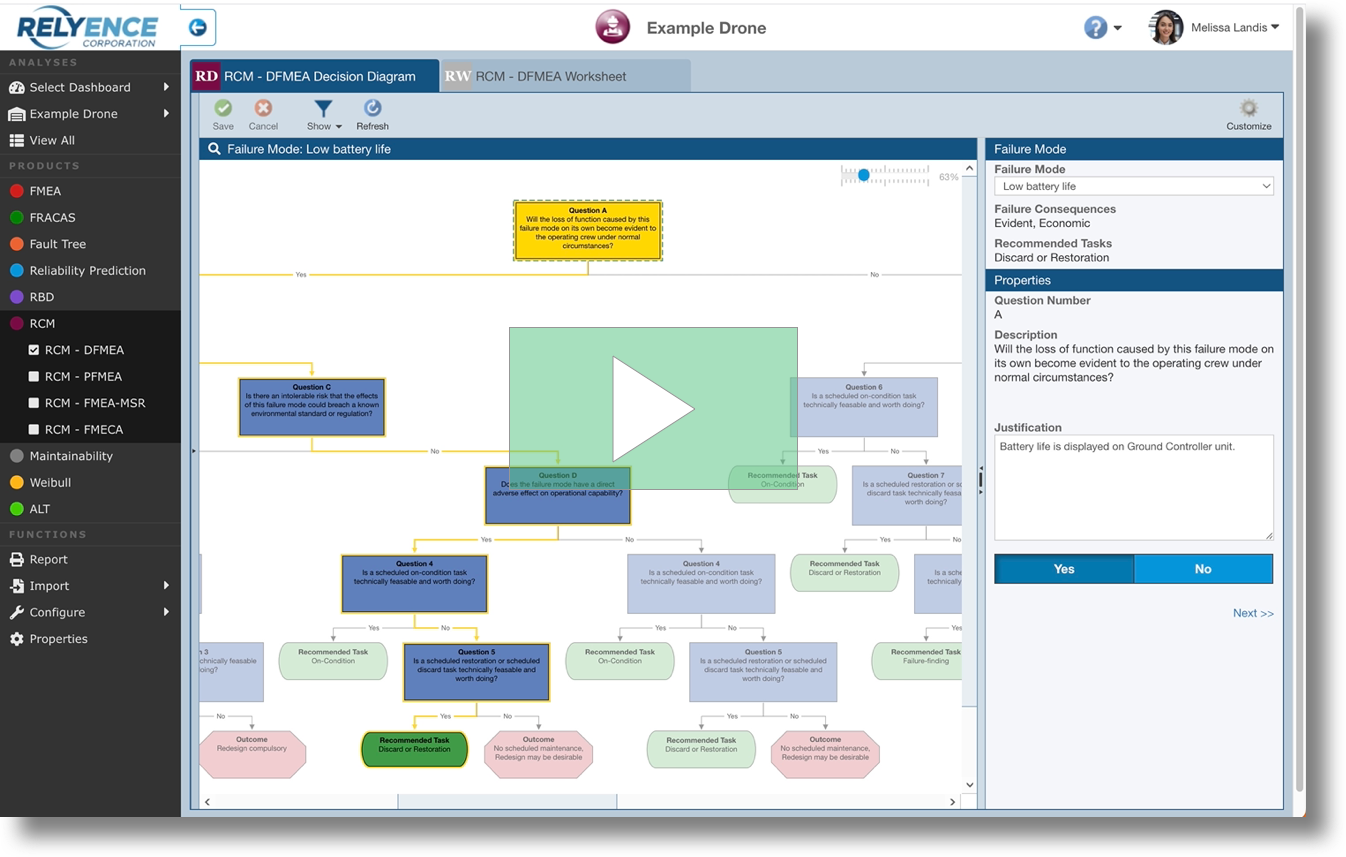

Relyence RCM is built to support your Reliability Centered Maintenance needs – whether driven by compliance requirements or your own internal goals and objectives. Select from the supplied templates supporting SAE JA1012, MIL-HDBK-2173, and NAVAIR 00-25-403 methodologies, or create a completely custom format.

RCM and FMEA Integration

Relyence RCM can be used as a stand-alone analysis tool; however, its streamlined integration with Relyence FMEA enables efficient RCM analyses. It works with any type of FMEA you perform: Design FMEAs, Process FMEAs, FMECAs, or FMEA-MSRs. And Relyence RCM is part of Relyence Studio, our high-powered, integrated, cross-product platform.

An Efficient RCM Tool

Take Relyence for a Test Drive!

Discover Relyence RCM

Get the details on how Relyence RCM meets all your analysis needs

Spotlight on Relyence RCM Software

Discover the unparalleled features that make Relyence RCM software the choice tool for Reliability Centered Maintenance analysis.

Reliability Centered Maintenance

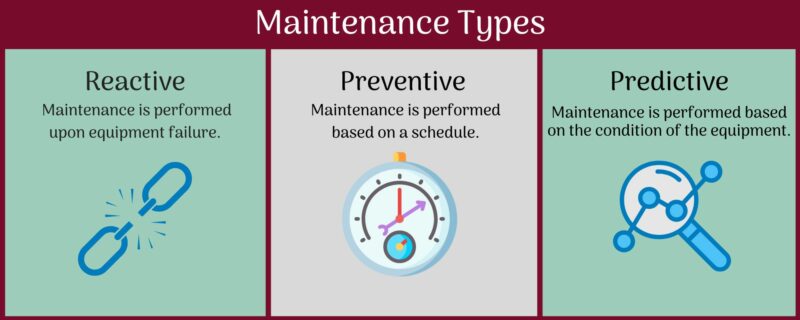

Reliability Centered Maintenance enables you to determine how to use all maintenance types to establish the most efficient maintenance program.

RCM Software – What & Why

Answering the key questions about RCM software tools

RCM, or Reliability Centered Maintenance, offers a strategy for maintenance program planning in order to optimize resources in the most efficient manner possible. RCM provides a methodology to keep equipment up and running safely, thereby minimizing downtime while using a cost-effective approach. RCM recognizes that not all equipment and assets are of equal importance, so maintenance strategies need to factor this prioritization into maintenance plans.

A commonly adopted approach for RCM analysis, as delineated in SAE JA1011, answers the following seven questions:

- What are the functions of the system?

- What are the ways the system can fail to function?

- What are the causes of the failures?

- What happens when it fails, or what are the consequences of failing?

- Does it matter if it fails?

- What can be done to prevent the failure?

- What can be done if the failure cannot be prevented?

From the comprehensive review of the potential system failures, a successful RCM analysis results in a well-defined maintenance plan.

Unexpected equipment failures can lead to devastating consequences. For example, if a manufacturing assembly line experiences a failure, the entire line is down until the repair is made. So not only do you incur the cost of repair, but also the costs of assembly line shutdown and subsequent restart.

Therefore, maintenance of complex equipment is a critical aspect in ensuring that downtime is minimized and costs are controlled. You cannot prevent all failures, but with a high quality maintenance program, you can ensure the detrimental effects of failures are minimized or prevented. However, you need to optimally create your maintenance program. Performing maintenance activities too often is an unnecessary waste of resources and capital.

RCM provides a way to help ensure you are intelligently balancing your maintenance activities in order to meet your objectives as efficiently as possible. Therefore, RCM improves uptime while also providing cost savings.

The key benefits of RCM are:

- Reduced costs – unnecessary maintenance tasks are eliminated.

- Optimal system performance – uptime is maximized and asset life is extended by efficient maintenance planning.

- Improved safety and reliability – prevention and/or mitigation of critical system failures means improved safety and system reliability.

- Improved teamwork – RCM works across the organization to reach shared goals.

The most effective RCM analyses are performed using software tools designed specifically for this purpose.

If you are looking for compliance to accepted RCM standards, such as SAE JA1011, SAE JA1012, MIL-HDBK-2173, and NAVAIR 00-25-403. make sure the software you choose supports those standards. RCM software should provide out-of-the-box support for the accepted standards and make it easy for you to get up and running in minimal time. Additionally, because flexibility is key in RCM analyses, your RCM tool should be easily customizable, enabling you to adapt the framework to your requirements and change as your process evolves.

Importantly, look for a tool that is part of a complete RAMS (Reliability, Availability, Maintainability, and Safety) platform so your tools work together seamlessly for ultimate efficiency. Specifically, your RCM tool should integrate and work in conjunction with your FMEA software.

Additionally, most professionals appreciate a browser-based toolset for easy accessibility and no installation requirements. If you prefer a cloud-based or an on-premise setup, be sure the tool you choose supports your needs. Other desirable features include role-based permissions, ease-of-use, intuitive design, and a top-notch customer service team.

Today’s professionals know that when performing RCM analysis, their choice of software is a critical decision. If the RCM software tool is too basic, the resulting RCMs are inconsistent, unmanageable, and slow to perform. The limitations of generic tools such as Excel swiftly become apparent once the analysis process gets into the details. If the tool is too complex to use, the process is cumbersome and results in frustration and poor-quality RCM analyses.

Relyence RCM provides a powerful and well-managed approach for Reliability Centered Maintenance analysis. It supports the most widely accepted RCM standards, including SAE JA1012, MIL-HDBK-2173, and NAVAIR 00-25-403. Relyence RCM is built on the Relyence Studio platform, which offers an array of features and functions to make your job easier and ensure your RCM analyses are performed efficiently and result in the most effective maintenance plans. For these reasons and more, Relyence is the tool of choice for RCM practitioners.

In addition to delivering a feature-rich and comprehensive RCM software tool, Relyence provides best-in-class in service and support. We are committed to our customers. We deliver results, we listen to customer ideas and suggestions, we continually innovate, and we answer emails and calls with speed and accuracy. It’s why we’ve become the name so many organizations trust for their reliability, quality, safety, and maintenance needs.

See how Relyence RCM can deliver for you. Start your free trial today!

Want to learn more?

Check out our blog for more information on Reliability Centered Maintenance analysis, Relyence RCM, and other reliability & quality topics.

Subscribe to Our eNewsletter

We won’t bombard you with emails! Our eNewsletter is timely and informative. And gets great reviews!

“Your Advisor is well written—simple (appealing since not cluttered), concise (efficient), and most importantly, technically informative (effective). Thank you!”

Tim A., Reliability-Risk Engineer

Relyence Advisor: Tools & Tips for the Reliability and Quality Professional

Note: You can unsubscribe at any time.

Why wait? Get your no-hassle free trial today!

See why Relyence is the name to rely on for excellence! Our Reliability Centered Maintenance software free trial is completely hassle-free – no downloads, no installations, no waiting. Simply open a browser and you’re ready to go with Relyence! You can start with our step-by-step tutorial if you prefer, or jump right in. Our RCM free trial is fully functional, so you can give us a complete test drive. Why wait? Get started today! If you’d like a personal demo, feel free to call 724.832.1900 or schedule at your convenience.