FMEA, or Failure Mode and Effects Analysis, and is a widely used, organized, systematic approach for performing failure analysis on your product, system, or process. FMEAs are typically customized to meet the needs of the organization; however, most are based on a recommended guideline from published standards. The newest standard gaining swift adoption for performing FMEA is the FMEA Handbook from AIAG & VDA.

In this article we will discuss important details from the standard and how to use Relyence FMEA to perform your AIAG & VDA FMEAs.

What is the AIAG & VDA FMEA Standard?

The AIAG & VDA standard, entitled FMEA Handbook, covers Design FMEA (DFMEA), Process FMEA (PFMEA), and Supplemental FMEA for Monitoring & System Response (FMEA-MSR). Published in cooperation between two widely recognized automotive industry groups, AIAG (Automotive Industry Action Group) and VDA (Verband der Automobilindustrie, or the German Association of the Automotive Industry) in June 2019, the AIAG & VDA standard is applicable to any organization performing design and process-based FMEAs. It is intended to replace the AIAG 4th Edition FMEA Manual.

For more details about the standard and information on purchasing, please visit the AIAG website.

AIAG & VDA FMEA Standard 7-Step Approach

Along with a thorough explanation of using FMEAs to meet customer needs, the handbook offers more focus on function-based FMEAs, provides general guidance for implementing a robust FMEA methodology, and introduces new concepts such as the 7-Step Approach for FMEAs.

The 7-Step Approach described in the AIAG & VDA standard is described in detail for DFMEAs, PFMEAs, and FMEA-MSRs, but can easily be applied to any type of FMEA performed. The 7-Step Approach includes:

- Planning and Preparation – identify the scope of analysis and determine strategies to focus on

- Structure Analysis – determine how to break down the system in subsystems, components, process work elements, etc.

- Function Analysis – describe the intended functions of each element from Step 2

- Failure Analysis – identify the potential failure modes, effects, and causes for each intended Function

- Risk Analysis – assign Severity, Occurrence, and Detection values for each item from Step 4 to prioritize the need for action

- Optimization – establish the prevention and detection actions required to reduce risks

- Results Documentation – record the complete results of the failure mode and effects analysis

You can find more details regarding each of the 7 steps in the AIAG & VDA handbook.

How to Perform AIAG & VDA FMEAs using Relyence FMEA

Relyence FMEA fully supports the AIAG & VDA standard for performing your FMEAs. As with all Relyence software, you can tailor the analysis as needed to meet your requirements. You can use the built-in AIAG & VDA defaults as-is or use them as a basis for creating a custom FMEA based on the AIAG & VDA standard.

In this section, we describe 7 key features and functions within Relyence FMEA designed to support FMEA based on the AIAG & VDA standard:

- Built-in AIAG & VDA Template

- Automated Higher and Lower Level Fields

- Boundary Diagrams

- Risk Assessment with Action Priority

- Failure Chains with Relyence FMEA SmartSuggestᵀᴹ

- Foundation FMEAs with Relyence Knowledge Banksᵀᴹ

- Support for FMEA-MSR

Built-in AIAG & VDA Template

Relyence FMEA includes a built-in template for performing FMEAs based on the AIAG & VDA standard. To use the AIAG & VDA template when creating a Relyence Analysis, simply choose the AIAG & VDA FMEA template from the dropdown list.

If you have an Analysis that want to update to use the AIAG & VDA FMEA template, you can use Relyence’s Template Transfer feature to easily convert your existing FMEAs to the new format. Template Transfer is available from the Manage Analyses feature in Relyence.

Automated Higher and Lower Level Fields

Relyence FMEA includes various FMEA fields that can be included on your FMEA Worksheet to support FMEAs following the AIAG & VDA standard. The built-in Next Higher Level and Next Lower Level fields provide useful reference information when working to enter or review details for a Focus Element. Relyence automatically populates these fields with appropriate information applicable to each Focus Element, thus saving you time and effort during the FMEA process.

In addition, these fields help with the understanding of Failure Chains, easily associating the Focus Element Failure Mode to the Next Higher Level Failure Effect and Next Lower Level Failure Cause.

Boundary Diagrams

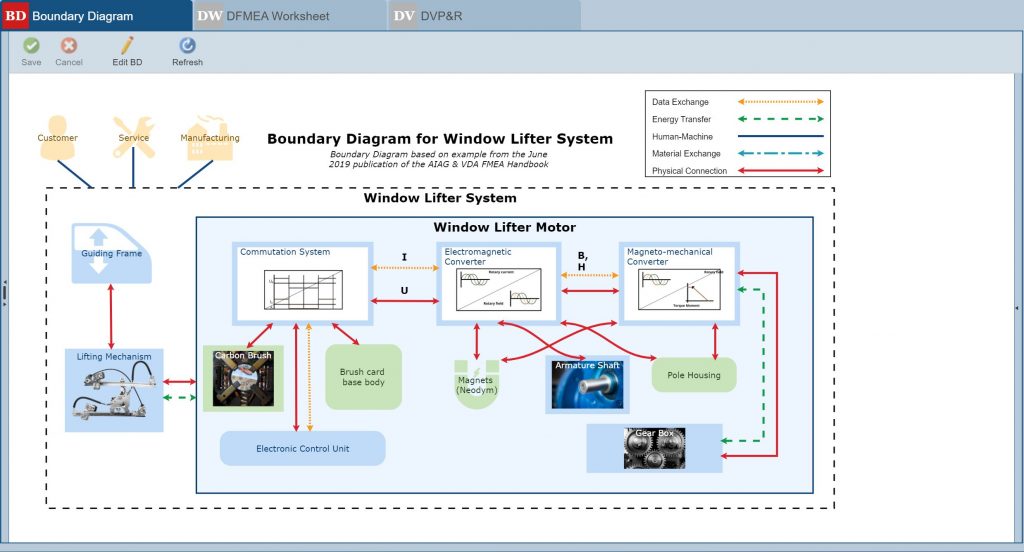

Boundary Diagrams are used to provide a visual representation of the components of a system including the interfaces between components and external factors, such as environmental effects and human interactions. They are an optional, but helpful, part of Failure Mode and Effects Analysis.

Typically used as the first step in the DFMEA process, Boundary Diagrams help to better define the scope of analysis. The intent of a Boundary Diagram is to improve the understanding of the system under consideration by providing a graphical diagram of its interactions with internal and external elements. They can be useful as an upfront brainstorming tool to ensure the scope of analysis is well understood and all appropriate factors are taken into consideration in the DFMEA.

Boundary Diagrams are typically constructed using a set of graphical elements that represent the components of a system and the interfaces between components and external factors. Relyence FMEA comes with a complete set of built-in components for creating your Boundary Diagrams. Or, diagram elements can be fully customized to meet your requirements. Additionally, interface data from your Boundary Diagram can be added as or connected to Functions in your DFMEA Worksheet.

Boundary Diagrams provide a graphical overview of a system’s components and connections to other elements. (Boundary Diagram is based on the example from the June 2019 publication of the AIAG & VDA Handbook.)

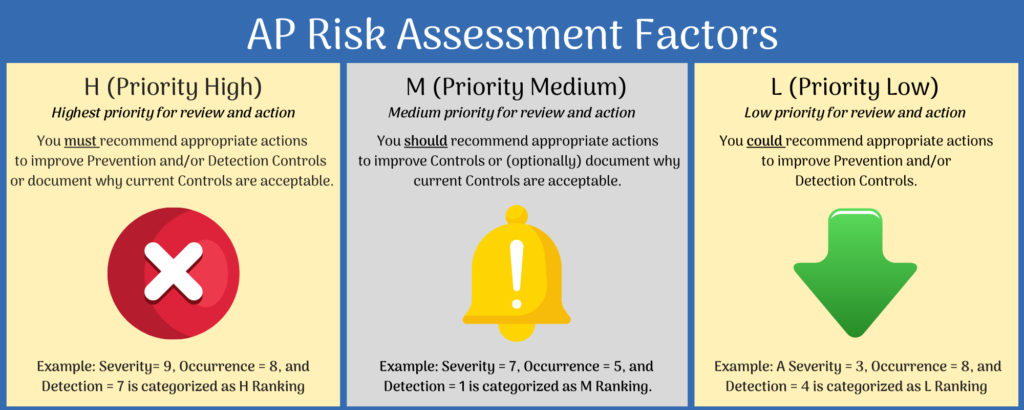

Risk Assessment with AP

The AIAG & VDA FMEA Handbook introduced Action Priority (AP) as a technique for risk assessment. AP replaces RPN, Risk Priority Number, from the AIAG 4th Edition standard. The previously used RPN criteria is the product of Severity * Occurrence * Detection. Similar to RPN, AP considers Severity, Occurrence, and Detection; however, it’s ranking system places the most emphasis on Severity, then Occurrence, and then Detection. Three AP levels of High, Medium, and Low are defined based on your Severity, Occurrence, and Detection values.

Relyence FMEA fully supports the use of AP for evaluating risk. Both the AP and Revised AP fields can be added to your FMEA Worksheets.

Failure Chains with Relyence FMEA SmartSuggest

Failure Chains assist in understanding the relationship between the Focus Element under consideration and the overall product or process being analyzed. In terms of the AIAG & VDA FMEA Handbook, this means associating the Focus Element Failure Mode to the Next Higher Level Failure Effect and Next Lower Level Failure Cause.

Relyence FMEA SmartSuggestTM offers a unique approach for keeping your FMEA data synchronized throughout your Analysis Tree hierarchy. As the name implies, FMEA SmartSuggest provides suggested FMEA data that should be considered for inclusion in your FMEA Worksheet. By analyzing your FMEA Worksheets that are completed across the various levels of your FMEA tree hierarchy, FMEA SmartSuggest develops a list of possible failure data to include on your current Worksheet. From the SmartSuggest panel, you can see recommended data suggestions and then choose those that are most appropriate for your analysis. For example, when working to enter Failure Modes, SmartSuggest will suggest Higher Level Causes and when working to enter Effects, SmartSuggest will suggest Higher Level Modes.

Foundation FMEAs with the Relyence Knowledge Bank

The central concept of Foundation FMEAs is to provide a databank of FMEA information from past analyses for optimal analysis efficiency. When utilized, Foundation FMEAs offer access to your historical data in a centralized place so it can be easily referenced and retrieved. This methodology ensures that lessons learned are retained and carried through to all your ongoing projects.

Depending on the organization’s usage, Foundation FMEAs can be employed as a place to store universal FMEA data that applies to all products – these FMEAs can also be known as baseline, generic, or best-practices FMEAs. Or, they can be tailored to more specialized data – for example, Foundation FMEAs could be created that apply to certain product lines, processes, manufacturing locations, etc. When this more specialized approach is chosen, the resulting failure information database can also be referred to as a family FMEA. The AIAG & VDA standard defines details regarding Foundation and Family FMEAs in section 1.3.6.

Relyence FMEA supports Foundation FMEAs with its innovative Knowledge BanksTM feature. With a few clicks, you can add any FMEA information from your FMEA to a Knowledge Bank – FMEA Functions, Process Steps, Failure Modes, Effects, Actions, and even full components or systems. Then, in future FMEAs, data can be easily retrieved from the Knowledge Bank using the flexible search feature.

Additionally, Knowledge Banks allow you to keep all your analyses organized and in sync. Data in the Knowledge Bank can be updated at any time and you can then push updates out to all your FMEAs tied to Knowledge Banks. This ensures that appropriate changes are propagated to all places the data is used within your system and process FMEAs.

Our blog post offers a thorough overview of using Relyence Knowledge Banks for Foundation FMEAs.

FMEA-MSR in Relyence FMEA

The AIAG & VDA FMEA Handbook also defines a new FMEA type: Monitoring and System Response FMEA, or FMEA-MSR. FMEA-MSRs supplement DFMEAs and consider how a product will fail when in use by the customer. The intent of FMEA-MSRs is to keep products safe and ensure that a product remains in compliance with regulations (such as environmental statutes) during customer use.

As with all FMEAs, FMEA-MSRs analyze potential failure modes and the resulting effects on the system. A main consideration of FMEA-MSRs is to determine if a customer will detect a failure if it occurs. FMEA-MSRs are most often used when systems include active or passive monitoring and response systems, such as a tire pressure monitoring system. Given that FMEA-MSR analyses can be used to ensure that functional safety goals are met, they can be used a part of ISO 26262 compliance requirements.

Relyence FMEA includes a supplied template for a FMEA-MSR Worksheet. You can use this Worksheet as-is, or modify it as needed to perform your Monitoring and System Response FMEAs.

Transitioning from Other FMEA Standards to AIAG & VDA

The AIAG & VDA handbook states that existing FMEAs developed using the AIAG 4th Edition FMEA Handbook may remain in their original form. This means that, if desired, you can keep all past and current FMEAs as is and use the AIAG & VDA standard as a basis for new analyses. However, the decision as to how and when to implement the AIAG & VDA approach for your FMEAs should be made based on your organization’s needs and requirements.

In preparation for using the AIAG & VDA standard for FMEA, you should begin to familiarize yourself with the new AIAG & VDA handbook, identify changes your organization must make to successfully transition to using the AIAG & VDA handbook, and consider training to help streamline the process.

If you are new to AIAG & VDA FMEAs, you can find a number of free resources listed on the AIAG website, along with the link to purchase a copy of the standard.

Conclusion

Relyence FMEA is a powerful platform that fully supports your failure mode and effects analyses. Designed to ensure the FMEA process is as easy and effective as possible, Relyence FMEA includes a broad array of features and functions that make it the best-in-class FMEA solution. Additionally, Relyence FMEA supports the most commonly used FMEA standards, including the AIAG & VDA standard.

Check us out today to see why Relyence FMEA has become the go-to platform for AIAG & VDA based Failure Mode and Effects Analyses! If you are interested in learning more about Relyence FMEA, sign up today for your own no-hassle free trial. Feel free to contact us to discuss your needs or schedule a personal demo.