Failure Mode and Effects Analysis (FMEA) is one of the most often-used and time-tested reliability engineering techniques. FMEA provides a comprehensive risk management framework. It offers an organized and structured approach to evaluating system or process failures and the risk associated with them. Its proven advantages show why time and time again, quality centric organizations turn to FMEA to improve their products and processes.

In this article, we examine one of the latest techniques intended to build on FMEA’s robust risk detection and mitigation strategies – Reverse FMEAs or RFMEAs. We will answer the 5 W’s of RFMEA in order to explain the key aspects and benefits of this useful methodology.

Foundations of RFMEA

Within the broad technique of FMEA, there are a few distinct types of FMEAs that can be employed depending on what is being analyzed. The primary types of FMEAs include:

- System / Functional FMEAs

- Design FMEAs

- Process FMEAs

- Service FMEAs

- Software FMEAs

- Manufacturing FMEAs

Each offers its own unique advantages based on its desired application. However, all are focused on the same function of risk assessment and the detection, elimination, and/or mitigation of critical risk events.

PFMEA can be used on any process, such as product manufacturing, emergency procedures, and software development. PFMEAs are broadly used throughout many industries and organizations to ensure processes are well controlled. Once a product moves from the design stage into production, PFMEA becomes vital to ensure that product quality is maintained during the manufacturing process. For the purposes of this article, we will focus on performing the Reverse FMEA technique when using Process FMEAs (PFMEA) on a manufacturing process. However, the same principles can be applied to any FMEA type.

Elements of PFMEA

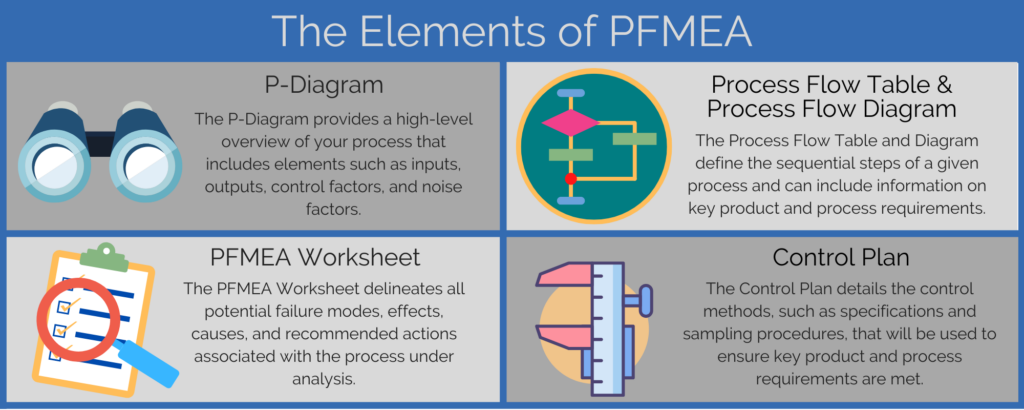

A PFMEA can often contain multiple elements that are designed to assist in process analysis. These may include:

- A P-Diagram to provide a high-level overview of the process, including factors such as desired inputs, expected and unexpected outputs, control factors, and noise factors.

- A Process Flow Diagram (PFD) and Process Flow Table (PFT) to lay out the required process steps along with their key product and process characteristics.

- The PFMEA Worksheet to delineate all potential failure modes, effects, causes, and recommended actions associated with the process under analysis.

- The Control Plan (CP) to detail the methods (specifications, evaluation techniques, sampling procedures, etc.) that will be used to control the PFMEA Product and Process Characteristics to ensure they meet requirements.

You can choose to use one or all of these elements for your PFMEA. Data across them is interrelated with the overall goal being efficient and accurate process analysis.

The Case for Adding RFMEA

When done correctly, PFMEA is a powerful and effective tool for process analysis and risk mitigation strategies. With its focus on the risk associated with each process step, it offers a comprehensive look at everything that is involved in the manufacturing process. However, it is most often performed prior to when the actual manufacturing process begins. Thus, it can be prone to disconnects between the process as intended and the process in actual use. This can be due to a variety of reasons. For example, the reliability engineering team completing the FMEA may not include manufacturing team members who possess critical knowledge of the process and possible problem areas. For this reason, it can be difficult for the FMEA team to anticipate all potential failure modes that can arise from human interaction, improper tool usage, environmental factors, etc.

These issues can lead to unexpected quality defects and warranty issues which can negatively impact the product as well as your company’s reputation. For this reason, analysts have recently been developing and taking a more proactive approach to managing these unexpected issues using RFMEA.

What is RFMEA?

Reverse FMEA is an approach to applying the proven FMEA risk management and mitigation processes in “reverse”, as you may expect! This technique was initially adopted in the automotive OEM space – notably by Ford. RFMEAs offer an approach to find new failure modes, causes, and areas of improvement that were missed during the FMEA process.

For the PFMEA case, RFMEA is a technique of attempting to uncover missing failure modes or inadequate prevention and detection controls. There can be many approaches in achieving this goal, including trying to make defective parts, attempting to bypass prevention or detection controls, or any other ways of attempting to uncover potential problems. In essence, the goal is to “break” the process and find failures that were not accounted for in the PFMEA. It is a proactive technique that aims to discover the cause of defects or quality issues before they occur. Remedies can then be put in place before production begins.

Is there an RFMEA Standard?

Currently, there is no specific standard related to Reverse FMEAs. This allows for maximum flexibility when designing your RFMEA process. Because you know your products and processes best, this flexibility enables you to develop an RFMEA process to effectively meet your needs. Thus, it is also of utmost importance that the RFMEA tool you choose be flexible and powerful.

When should I do an RFMEA?

Because there is no standardized approach to RFMEAs, this also means you can choose when and where to engage the RFMEA process. You could choose to perform an RFMEA at your desired equipment vendor’s facility prior to shipping, immediately upon equipment arrival at your facility, during a pre-production sample run, or even after product launch. Or, if desired, at each step along the way! In fact, it can be advantageous to perform an RFMEA both at your vendor’s facility and then upon installation on your production floor. Performing an RFMEA at your vendor’s facility can help ensure you have the ability to design-in controls prior to equipment arrival. An RFMEA at your facility could then be used to verify those controls are effective on your manufacturing floor.

In general, the earlier you are able to perform RFMEAs the better, as you can more easily make any needed changes to the production process. As you progress further towards official production, often your options become more limited, and changes become more difficult and expensive to make.

Where do I do an RFMEA?

Whereas FMEAs are often completed with a cross-functional team during the design and development process, RFMEAs associated with a manufacturing process must be conducted on the manufacturing floor during operation. There can be a variety of approaches to perform your RFMEA. For example, each equipment manufacturer can perform an RFMEA on their piece of equipment. Or, the shop manager can walk the floor and perform the RFMEA on the process as a whole. Because of the flexibility offered by RFMEAs, you can choose any approach that best suits your organization.

Who should perform RFMEAs?

The benefits of a robust RFMEA process can be realized at any organization that already employs FMEA. The RFMEA technique was originally designed and intended for organizations that manufacture a physical product, so its framework is most suitable there. However, due to its flexibility, RFMEA can be performed by any organization that performs FMEAs as part of their reliability program. RFMEAs are beneficial for any business looking to gain additional insight into their risk management procedures once the FMEA is completed.

For RFMEAs associated with the manufacturing process, the RFMEA team should include members who are familiar with the equipment that will be used during production. This can mean the equipment operators themselves, the shop floor manager, or anyone else with a deep understanding of the intended process. Additionally, the team can and should include any team members who have an interest in product success in any capacity. A well-rounded team is key to effective RFMEAs. Because the goal of the RFMEA is to uncover missing failure modes or inadequate prevention and detection controls, it is important that the RFMEA team understands the importance of proactively finding and correcting process issues. Having an RFMEA team that is both quality-driven and possesses a thorough understanding of the equipment and processes ensures you will get the most possible out of your RFMEA.

Why should I perform RFMEAs?

The main benefit of performing RFMEAs is to discover failure modes and other associated risk data that was missed in the earlier phases of the FMEA process. RFMEA provides feedback to your FMEA Worksheet that ensures your failure coverage is as complete and accurate as possible. You can be certain that you are taking into account all failure data and that the controls you have in place are effective.

In short, RFMEAs ensure that your FMEAs and process controls are as robust as possible prior to moving into full production. RFMEAs can greatly assist in your continuous improvement efforts and help you to achieve your organization’s overall reliability goals. In addition, because they are performed prior to full production, they can save you overall costs in the long term. Process issues discovered at an early stage enable you to rectify problems prior to full-scale production, thereby avoiding potentially costly downtime issues or stoppages in the future. Additionally, you are more likely to catch and prevent any major issues that could cause costly returns, product recalls, damaged company reputation, and other COPQ (Cost of Poor Quality) concerns.

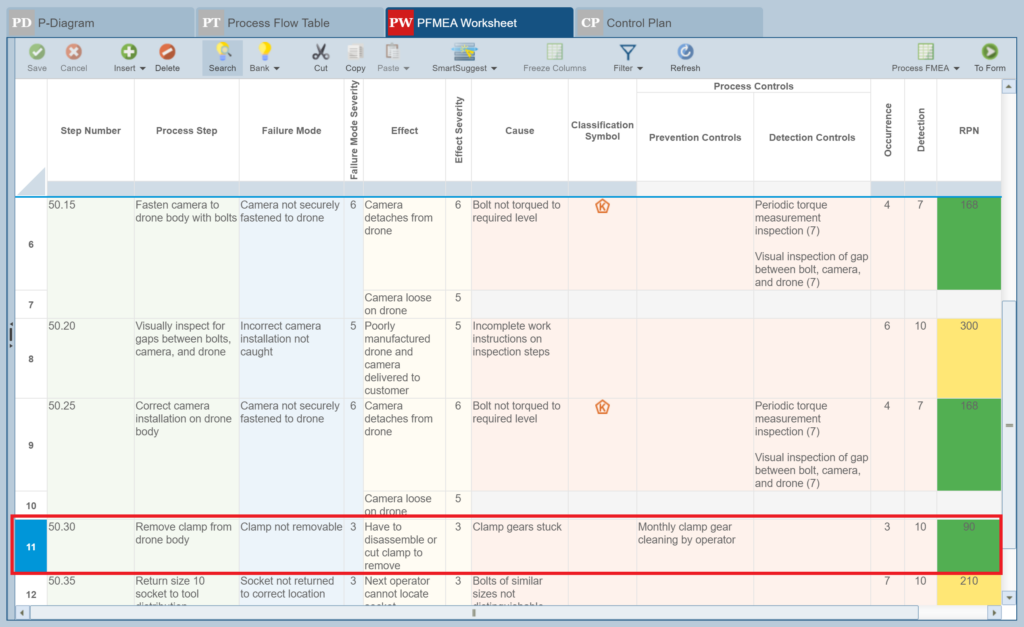

Example RFMEA

As an example, let’s look at a way to use RFMEA methodology on a PFMEA of the process of attaching a camera to a drone. For this example, we’ll focus on Step 50.30 “Remove clamp from drone body” of our completed PFMEA.

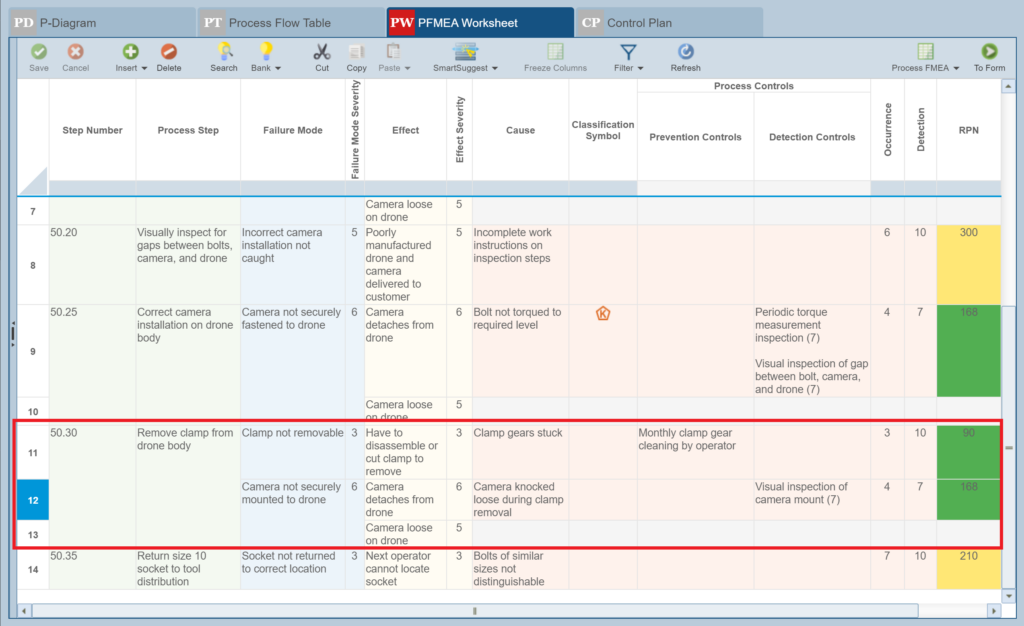

We see that there is a single Failure Mode noted: “Clamp not removable.” Now, we head to the manufacturing floor and observe the process in action. While there, we see that during one of the removals, the clamp hit the camera attachment and knocked it loose. This could very likely lead to a failure caused by a loose camera. We determine that this newly discovered failure mode should be added to our existing PFMEA.

Returning to the PFMEA, we can then determine the best approach for risk mitigation. Perhaps we add a secondary visual inspection after clamp removal. Or perhaps we decide a better approach may be to reorder our Process Steps and perform visual inspection after clamp removal.

This is a small example of how performing RFMEA on your manufacturing process can be key in discovering potential failures not recognized earlier. As you go about your RFMEA methodically, you can see how this technique can play a vital role in quality improvement. Also, because FMEAs provide a wealth of knowledge that can be reused in future designs, your RFMEA efforts have long-lasting impact.

Conclusion

RFMEA is a powerful technique to uncover potential failure modes and areas of improvement that were missed during the FMEA process. Additionally, performing RFMEAs ensures you create a quality-driven environment at your organization and highlights the importance of catching potential failures before they occur.

Relyence FMEA offers a feature-rich and fully customizable off-the-shelf software solution for performing FMEAs and RFMEAs. It combines out-of-the-box support for Process Flow Diagrams, Boundary Diagrams, P-Diagrams, and more with an array powerful features, such as Knowledge Banks, SmartSuggest, AutoFlow, and full Workflow capabilities, to allow you to create a robust and effective RFMEA program.

Check out Relyence FMEA today. Sign up for a completely free no-hassle trial, schedule a personal demo at your convenience, or contact us to speak to one of our knowledgeable representatives.