There are a wide range of well-established and accepted evaluation techniques that form the basis of sound reliability and quality engineering practices. Often, these techniques are based on industry-adopted compliance standards that have been developed to ensure product and service reliability and quality. In many cases, companies turn to software tools to adhere to these compliance standards. Specifically, reliability software tools play a crucial role in helping organizations meet compliance requirements. We’ll review a number of compliance-related factors and see how reliability software tools can help organizations achieve compliance requirements:

- Safety and Risk Management

- MTBF and Mission Viability

- Trackable Corrective Action

- Fault Tolerance and Redundancy

- Service and Repair Regulation

Safety and Risk Management

Safety and risk management are paramount in any industry. Encompassing measures designed to prevent accidents, protect personnel, and mitigate potential hazards, it plays a critical role in maintaining safety. Compliance requirements ensure that safety protocols are in place and consistently adhered to. These requirements span various aspects, including occupational health and safety regulations, industry-specific standards, and environmental protection laws.

Compliance standards also provide guidance on various risk assessment and mitigation strategies that organizations can implement to achieve risk management goals. Compliance with safety and risk management standards not only minimizes risk and ensures safety, but also demonstrates a commitment to ethical conduct.

FMEA

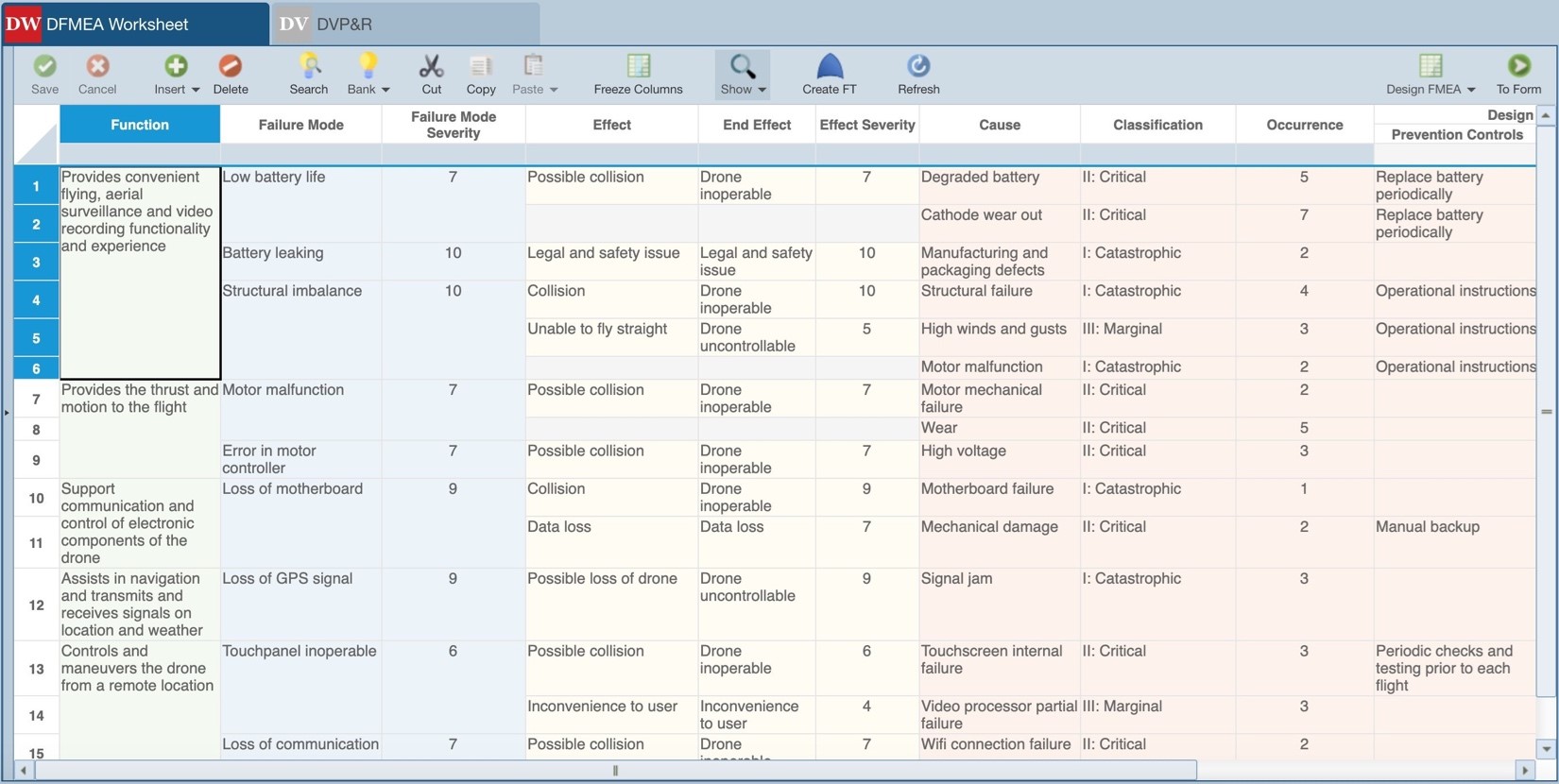

FMEA (Failure Mode and Effects Analysis) is a widely adopted technique for risk assessment and mitigation for a product, system, or process. FMEA is required for regulatory compliance in certain high-risk industries, such as medical devices. In many other cases, organizations perform FMEA in order to control risk, even if not required by regulatory agencies.

To perform a Failure Mode and Effects Analysis, analysts consider all possible or potential failure modes, evaluate their associated risk factors based on their level of severity, and determine ways to prevent, mitigate, or detect those failures deemed most critical. recommended action plans based on the results from this analysis. FMEAs provide a well-accepted approach for risk assessment and are invaluable for achieving and continuously improving your quality goals.

FMEA Standards

FMEAs may be required to be performed based on an established standard, such as:

- SAE J1739: Potential Failure Mode and Effects Analysis in Design (DFMEA), Potential Failure Mode and Effects Analysis in Manufacturing and Assembly Processes (PFMEA)

- ARP 5580: Recommended Failure Modes and Effects Analysis (FMEA) Practices for Non-Automobile Applications

- MIL-STD-1629A: Procedures for Performing a Failure Mode, Effects, and Criticality Analysis

- AIAG & VDA: FMEA Handbook

FMEA is a widely adopted technique for risk assessment and mitigation for a product, system, or process.

Fault Tree Analysis

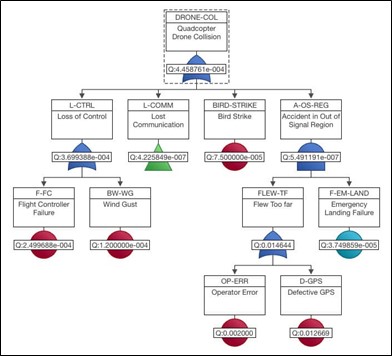

Fault Tree Analysis (FTA) is a Probabilistic Risk Assessment (PRA) technique that offers a top-down deductive approach used to analyze risk and safety issues. Starting with a highly undesirable or catastrophic top-level event, FTA employs Boolean logic to model the effects of low-level events which ultimately may lead to the top-level failure. To run an FTA, users construct a graphical fault tree diagram using Boolean logic gates that represent the relationships between events that could lead to a top-level failure. The lowest-level events on the fault tree, known as Basic events, are described by mathematical distributions, or models, which represent their probability of occurrence. The fault tree computational engine then determines the probability of the occurrence of the top-level event based on the lower-level event probabilities and Boolean logic relationships.

Fault Tree Analysis is a PRA technique that uses basic Events and Boolean logic gates to determine the risk of a catastrophic top-level event.

Fault Tree Standards

Some examples of compliance standards used when performing FTAs include:

- IEC 61025: International Standard for Fault Tree Analysis (FTA)

- NUREG-0492: U.S. Nuclear Regulatory Commission Fault Tree Handbook

- MIL-HDBK-338: Electronic Reliability Design Handbook

- SAE ARP475A: Guidelines for Development of Civil Aircraft and Systems

- SAE ARP4761: Guidelines and Methods for Conducting the Safety Assessment Process on Civil Airborne Systems and Equipment

MTBF and Mission Viability

Some compliance requirements are based on meeting a defined MTBF (Mean Time Between Failure) goal or specific. The most common tool used for this analysis is Reliability Prediction software.

Reliability Prediction

A Reliability Prediction is a way to analyze an electro-mechanical system to determine its predicted failure rate, MTBF, and mission success. Reliability Predictions take into account all the components in your system along with design and environmental parameters known to affect reliability such as operating stresses, temperature, environment, and procurement quality level. Reliability Predictions are often used in early design to estimate likely reliability performance levels. Using the results of these analyses, engineers can make design changes early in the lifecycle when it is most crucial and cost effective.

Reliability Prediction Standards

Reliability Predictions are most often performed based on a known Reliability Prediction standard. Reliability Prediction standards that may be required to be used for compliance include:

- MIL-HDBK-217: Reliability Prediction of Electronic Equipment

- Telcordia SR-332: Reliability Prediction Procedure for Electronic Equipment

- IEC 61709: Electric components – Reliability – Reference conditions for failure rates and stress models for conversion

- SN 29500: Siemens Failure Rate of Components

- 217Plus: Reliability Prediction Models

- NSWC Mechanical: Handbook of Reliability Prediction Procedures for Mechanical Equipment

- ANSI/VITA 51.1: Reliability Prediction MIL-HDBK-217 Subsidiary Specification

- NPRD/EPRD: Nonelectronic Parts Reliability Data/Electronic Parts Reliability Data

Using the results of Reliability Prediction analysis enables engineers to make design changes early in the product lifecycle to improve a system’s reliability performance.

Trackable Corrective Action

Oftentimes, compliance standards require an organization to use a trackable corrective action system. While a specific corrective action system is not typically described in detail in a standard, an organization must define their corrective action system and verify that they adhere to it.

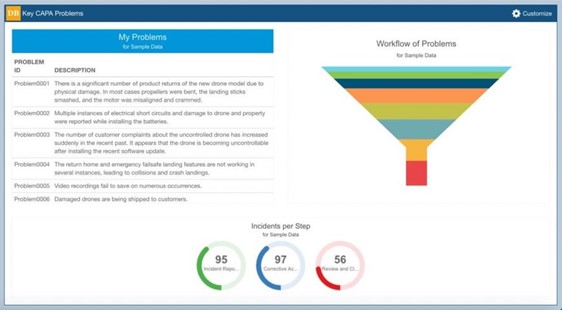

CAPA and FRACAS

CAPA (Corrective and Preventive Action) and FRACAS (Failure Reporting, Analysis, and Corrective Action System) are management systems for handling issues that arise with products or processes. When implemented, these corrective action systems provide a closed-loop process for effectively managing any type of failure, complaint, incident, issue, problem, or concern. They ensure that as incidents arise, they are captured and subsequently tracked until they have been properly addressed.

Corrective Action Standards

Some compliance standards where CAPA and FRACAS are key elements include:

- ISO-9001: ISO Standard for Quality Management Systems (QMS)

- MIL-STD-2155: Failure Reporting, Analysis, and Corrective Action System

- MIL-STD-785: Reliability Program for Systems and Equipment Development and Production

- ISO/TS 16949: Quality Management Systems – Particular requirements for the application of ISO 9001 for automotive production and relevant service part organizations

- AS 9100: Quality Systems – Aerospace – Model for Quality Assurance in Design, Development, Production, Installation and Servicing

CAPA and FRACAS processes ensure that incidents are captured and tracked until they have been properly addressed.

Fault Tolerance and Redundancy

Many compliance requirements for complex systems relate to ensuring system availability and minimizing downtime. Fault tolerant systems are crucial to many industries such as telecommunications, power, manufacturing, nuclear, and aerospace. For example:

- The nuclear power sector must meet strict fault tolerant guidelines and must ensure low probabilities of failure. In this industry, NRC (Nuclear Regulatory Commission) standards center on using PRA (Probabilistic Risk Assessment) in order to achieve risk requirements.

- In the aerospace sector, manufacturers developing space-based products must often rely on redundant systems in order to ensure operations continue when repairs are not an option.

Reliability tools help analyze fault-tolerant systems with redundancy and failover mechanisms. This is crucial for meeting compliance requirements related to system availability and minimizing downtime. Several reliability tools are built to aid in designing and developing systems that meet these vital requirements. Fault Tree Analysis (FTA) and Reliability Block Diagram (RBD) are two modeling tools which are often used to meet these demands.

Fault Tree Analysis

As previously noted, FTA is a type of Probabilistic Risk Assessment (PRA) tool that provides a well-structured approach for risk assessment. One of the keys goals of FTA is to ensure that the probability of occurrence of high-risk failures is minimized. FTA helps fields like the nuclear power industry comply to their strict fault tolerant requirements.

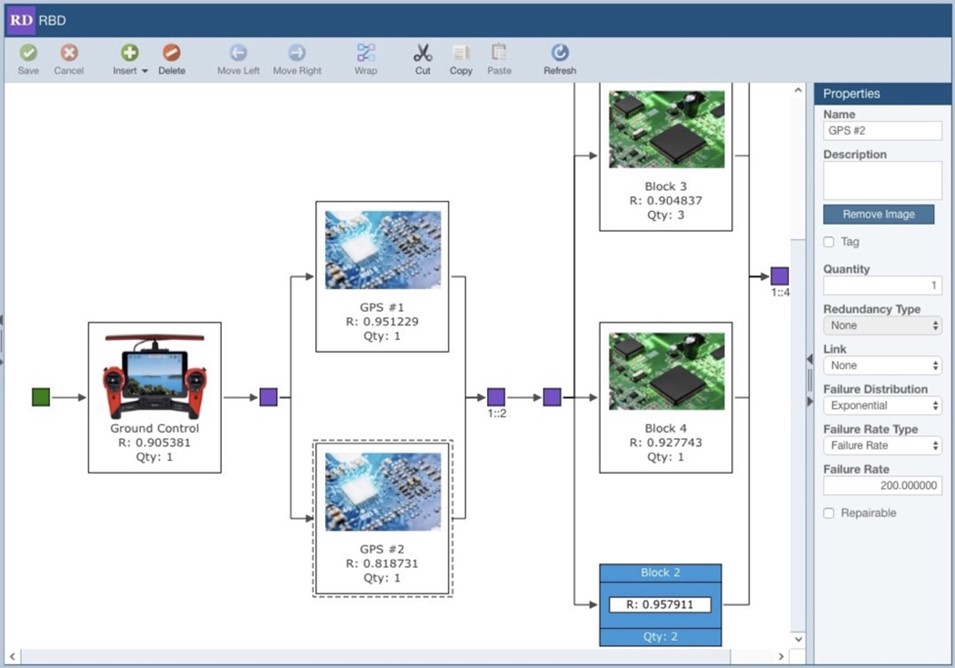

RBD Analysis

RBD analysis is a methodology for assessing the failure or success paths through a complex system. RBDs are created in a visual format, using blocks to represent components or elements of a system, and the connections between those blocks to indicate their relationships to one another. = RBDs are often used to assess the impact of redundant components or redundant paths in a system. Redundancy means that, when a component or path fails, a secondary component or path can take over to keep the system operational.

RBD analysis is a methodology that uses a visual format to assess the failure or success paths of a complex system, often those that incorporate redundancy.

Service and Repair Regulation

Service and repair operations are crucial components within various industries that ensure the functionality, safety, and longevity of equipment, machinery, and systems. Compliance requirements play a pivotal role in regulating these operations and ensure that organizations adhere to legal obligations, industry standards, and manufacturer specifications.

For example, aviation companies must comply with specific maintenance plans to retain their airworthiness certifications. Common recommended maintenance tasks for airplanes incorporate parts replacement or overhaul according to specified time intervals.

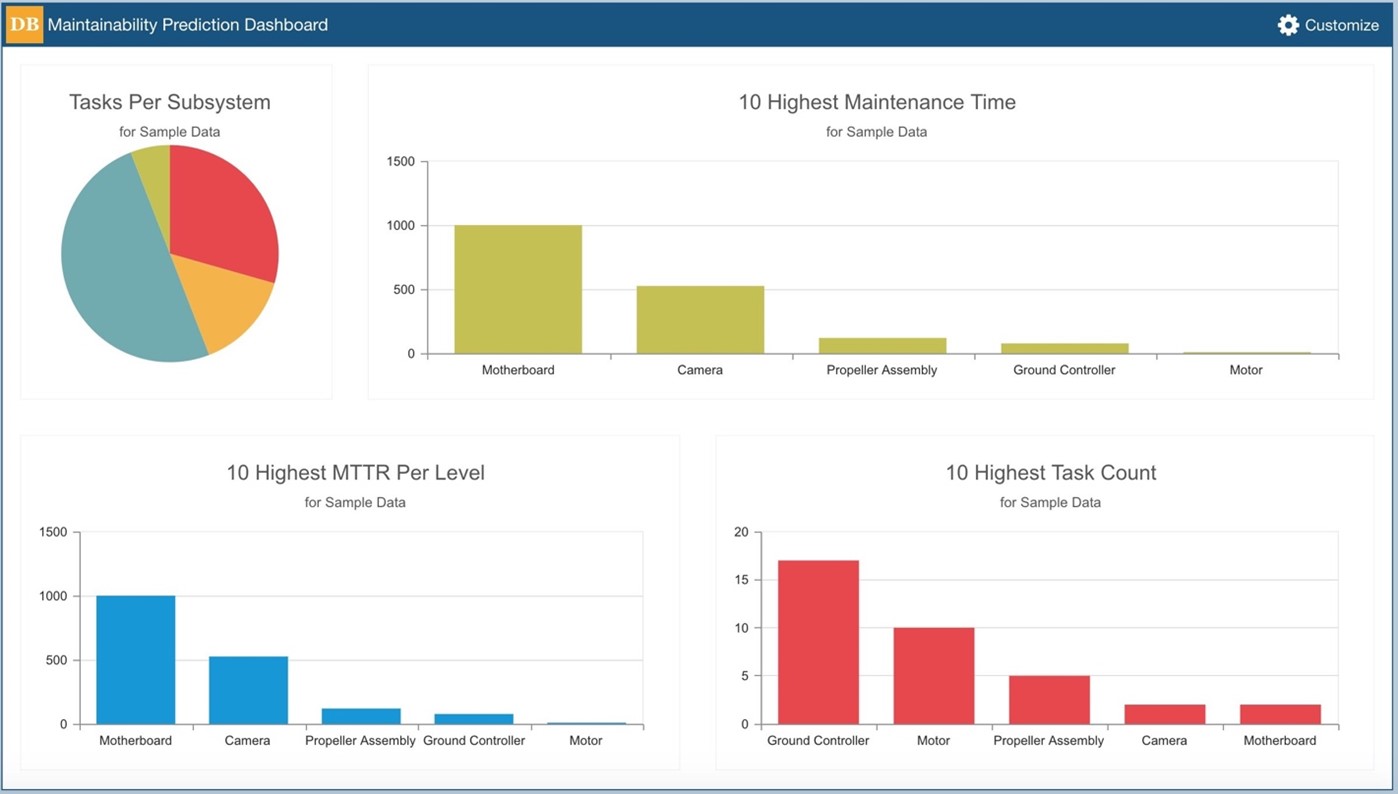

Maintainability Prediction

Maintainability is an important aspect in overall system performance and continuous improvement efforts. Assessing your repair and maintenance times is a crucial factor in assessing your product or system availability. For example, if a system fails but can be repaired quickly, then overall system uptime, or availability, is high. Additionally, repair and maintenance activities need to be optimized and performed in an efficient manner to maximize system uptime and achieve performance goals. Doing an upfront assessment of these metrics allows analysts to ensure product maintenance and repair procedures comply with service goals and objectives. Maintainability Prediction techniques evaluate repair procedures and allow for a predictive assessment of repair metrics.

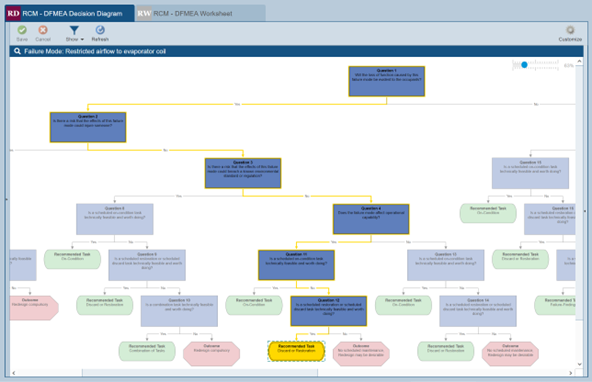

RCM

RCM, or Reliability Centered Maintenance, offers a strategy for maintenance program planning in order to optimize resources in the most efficient manner possible. RCM provides a methodology to determine efficient strategies to keep equipment up and running safely using a cost-effective approach, thereby minimizing downtime. RCM recognizes that not all equipment and assets are of equal importance, so maintenance strategies need to factor this prioritization into maintenance plans. The goal of RCM analysis is to develop a well-defined maintenance plan.

A commonly adopted approach for RCM analysis answers the following questions:

- What are the functions of the system?

- What are the ways the system can fail to function?

- What are the causes of the failures?

- What happens when it fails, or what are the consequences of failing?

- Does it matter if it fails?

- What can be done to prevent the failure?

- What can be done if the failure cannot be prevented?

RCM analysis provides a methodology to determine an efficient and cost-effective maintenance program.

Maintainability Prediction and RCM Standards

Maintainability Predictions typically are performed to a specific military standard, while there are several commonly used RCM standards:

- MIL-HDBK-472: Maintainability Prediction

- SAE JA1011: Evaluation Criteria for Reliability Centered Maintenance (RCM) Processes

- SAE JA1012: A Guide to the Reliability-Centered Maintenance (RCM) Standard

- MIL-HDBK-2173: Reliability-Centered Maintenance Requirements for Naval Aircraft, Weapons Systems and Support Equipment

- NAVAIR 00-25-403: Guidelines for the Naval Aviation Reliability-Centered Maintenance Process

A Maintainability Prediction Dashboard offers an overview of important maintenance and repair metrics.

The Relyence Studio Suite

The Relyence Studio suite is a powerful platform that encompasses all the reliability and quality software tools noted here in one integrated platform: FMEA, FRACAS, Fault Tree, Reliability Prediction, RBD, RCM, and Maintainability Prediction—in one integrated framework. If you perform more than one type of analysis, you do not have to engage a separate stand-alone tool for each. For example, if you perform both FMEA and Reliability Prediction, Relyence Studio allows you to navigate between the two with ease in a single tool. There are numerous additional advantages to this design approach:

- UI Consistency: The user interface look-and-feel remains the same, which makes learning the tool easy and keeps the UI consistent across all types of analyses.

- Data Sharing: Because the Relyence platform is built on one foundation, data is seamlessly shared between analysis tools, providing streamlined and efficient data handling.

- Ability to Grow: You can start with a single analysis tool and then add on as your needs or requirements grow and evolve.

- Ease of installation: No matter how many tools you use, there is only one install.

- Ease of maintenance and updates: Updates and maintenance need only to be managed for a single software package.

Conclusion

The suite not only encompasses all the most often used reliability and quality analytical tools but also supports all the compliance standards noted in this article. Out-of-the-box support for these standards helps you to achieve and maintain your compliance requirements with ease. For an overview of additional powerful features Relyence employs to help with compliance requirements, download our white paper.

Talk to us today about your needs, give Relyence Studio a completely hassle-free test run, or schedule a time to talk with a team member and get a personalized demonstration of our toolset.